Here are some frequently asked questions (FAQs) about 1 Ton Gantry Cranes to help clarify common inquiries and considerations for those interested in this type of lifting equipment:

What is a 1 Ton Gantry Crane?

A 1 Ton Gantry Crane is a versatile and portable lifting device designed to handle loads up to one ton. It is commonly used in various industrial and commercial settings for material handling tasks.

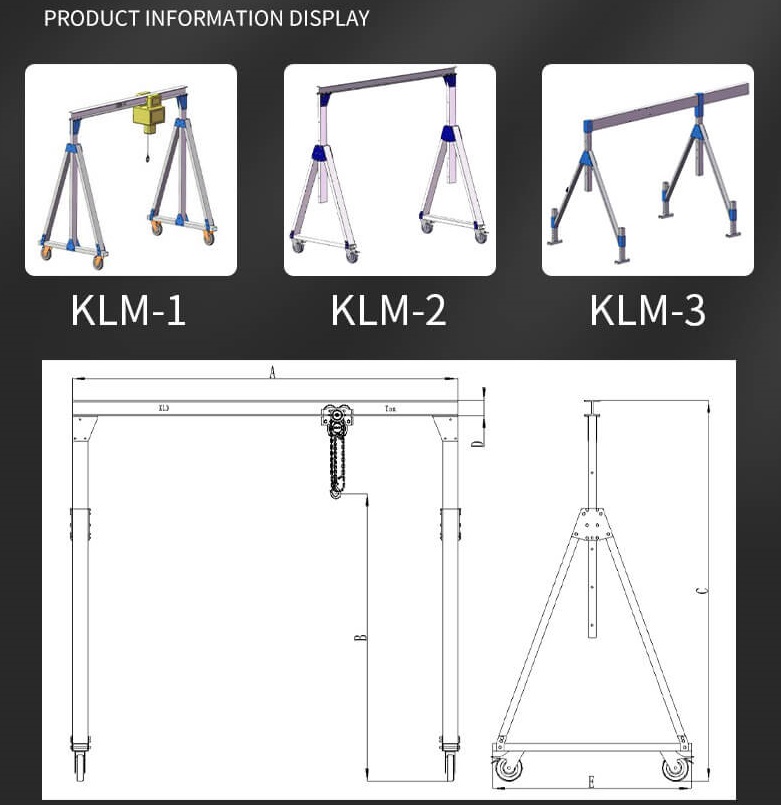

What types of 1 Ton Gantry Cranes are available?

Types include fixed, adjustable, portable, motorized, telescoping, and semi-gantry cranes, each offering specific features to accommodate different operational environments and needs.

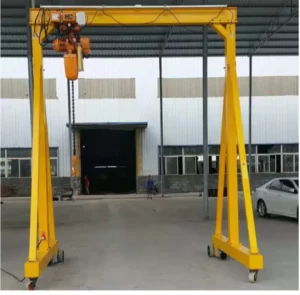

Can a 1 Ton Gantry Crane be used outdoors?

Yes, many 1 Ton Gantry Cranes are designed for both indoor and outdoor use, especially models with weather-resistant features such as corrosion-resistant paint and structural components.

How do I choose the right type of 1 Ton Gantry Crane for my application?

Consider the nature of the tasks, the environment in which the crane will operate, and specific requirements like mobility, height adjustability, and span width. Each type offers unique advantages that could align with different operational requirements.

Are 1 Ton Gantry Cranes customizable?

Yes, many manufacturers offer customization options for their gantry cranes, including adjustable spans, heights, and the addition of motorized trolleys, to better fit specific application needs.

What safety features are important for a 1 Ton Gantry Crane?

Look for cranes with built-in safety features such as overload protection, emergency stop buttons, and anti-collision systems to ensure safe operation.

What maintenance is required for a 1 Ton Gantry Crane?

Regular maintenance includes checking and lubricating moving parts, inspecting structural components for signs of wear or damage, and ensuring all safety devices are functioning properly.

Can I operate a 1 Ton Gantry Crane on uneven surfaces?

While some models with specially designed casters can handle slight irregularities, for optimal safety and performance, the crane should operate on a flat, stable surface.

How much space is required to operate a 1 Ton Gantry Crane effectively?

The required space will depend on the crane’s design and the operational area. Ensure there is enough clearance around the crane for safe movement and operation.

Where can I purchase a 1 Ton Gantry Crane?

1 Ton Gantry Cranes can be purchased from manufacturers specializing in lifting equipment, through industrial machinery distributors, or from online suppliers offering industrial lifting solutions.

These FAQs cover essential information to guide potential buyers and users in making informed decisions when considering a 1 Ton Gantry Crane for their lifting needs.