Here are the top 10 frequently asked questions about 1-ton jib cranes, which could be helpful for users considering this equipment for various industrial applications:

1. What is a 1-ton jib crane?

A 1-ton jib crane is a type of crane designed with a horizontal arm (jib) that supports a movable hoist fixed to a wall or column. It is used to lift and move loads up to one ton (1,000 kilograms).

2. Where are 1-ton jib cranes typically used?

These cranes are commonly used in small workspaces such as workshops, manufacturing facilities, automotive repair shops, and warehouses where efficient use of space and precise handling of materials are required.

3. What are the different types of 1-ton jib cranes?

There are several types of jib cranes, including wall-mounted, free-standing, and mast-style jib cranes. Each type serves different spatial and structural requirements.

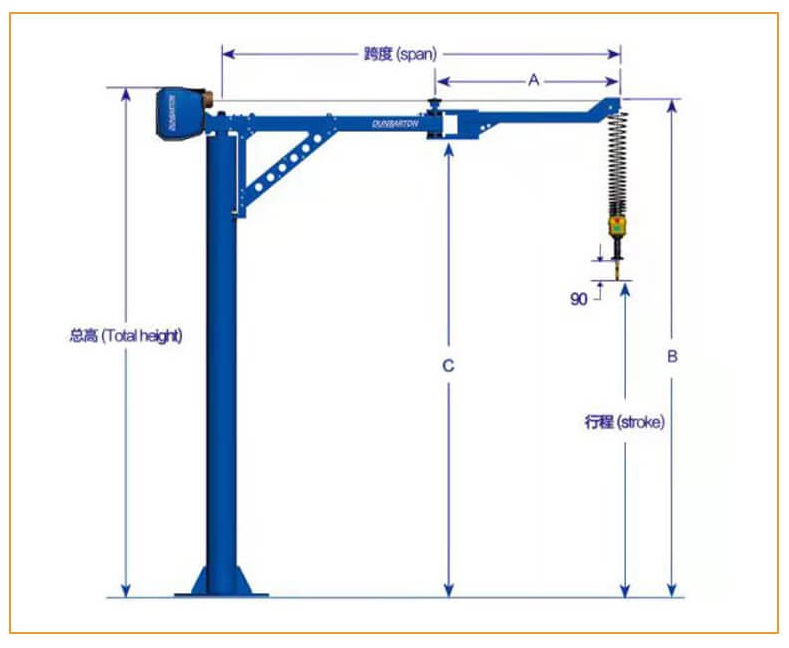

4. How much space is required to install a 1-ton jib crane?

The required space depends on the type of jib crane and the length of the arm. Wall-mounted cranes save floor space, while free-standing cranes need a solid foundation. Always ensure adequate clearance for the full rotation of the arm.

5. Can a 1-ton jib crane be customized?

Yes, jib cranes can be customized in terms of arm length, type of mount, and mobility options. Additional features like motorized rotation and special hoist types can also be integrated based on specific needs.

6. What safety features are included in 1-ton jib cranes?

Safety features typically include overload protection, emergency stop functions, and limits switches to prevent over-travel of the hoist. Regular inspections and maintenance are also crucial for safe operation.

7. How does a 1-ton jib crane operate?

Operation involves using the hoist to lift and lower loads, while the jib arm allows for horizontal movement. This can be controlled manually or with electric/air-powered systems depending on the crane model.

8. What is the maintenance protocol for a 1-ton jib crane?

Maintenance generally includes regular lubrication of moving parts, inspection of the hoist and cables for wear and tear, and checking structural integrity. Detailed maintenance schedules can vary based on the manufacturer’s recommendations.

9. How long does a 1-ton jib crane last?

With proper maintenance and care, a 1-ton jib crane can last many years. The longevity depends on the frequency of use, environmental conditions, and adherence to maintenance guidelines.

10. Where can I buy a 1-ton jib crane and what should I expect to pay?

1-ton jib cranes can be purchased from industrial equipment suppliers or directly from manufacturers. Prices vary widely based on the crane’s specifications and custom features, ranging from a few thousand to over ten thousand dollars.

These FAQs should provide a solid foundation of knowledge for anyone looking into purchasing or using a 1-ton jib crane in their operations.