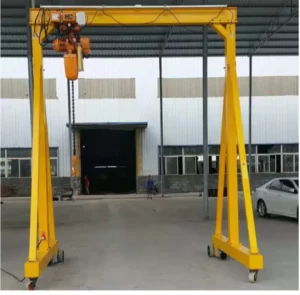

Here are some frequently asked questions (FAQs) about 10 Ton Gantry Cranes to help address common inquiries and considerations for those interested in this type of lifting equipment:

What are the primary uses of a 10 Ton Gantry Crane?

A 10 Ton Gantry Crane is commonly used in manufacturing, warehousing, construction, and shipping industries for lifting and moving heavy objects, such as containers, large machinery, and construction materials.

Can a 10 Ton Gantry Crane be customized?

Yes, most gantry cranes can be customized according to specific requirements such as span, height, type of movement (manual or motorized), and additional features like telescopic beams or adjustable spans.

What safety features are standard on a 10 Ton Gantry Crane?

Standard safety features include overload protection, emergency stop buttons, limit switches to prevent over-travel, and anti-collision devices. Ensuring regular maintenance and operator training is also crucial for safety.

How much space is needed to operate a 10 Ton Gantry Crane effectively?

The required space depends on the type of gantry crane and the operation’s scope. It’s important to consider the crane’s span, the height of the lift, and the maneuvering area around the crane. Planning should include sufficient clearance for safe operations.

Is a 10 Ton Gantry Crane movable?

While fixed gantry cranes are stationary, many models, such as portable or rail-mounted gantry cranes, are designed to move along a track or have wheels for easy relocation to where they are needed within a facility.

What maintenance is required for a 10 Ton Gantry Crane?

Regular maintenance should include lubricating moving parts, inspecting structural components for signs of wear or damage, checking electrical systems, and ensuring all safety devices are functioning properly. Detailed maintenance schedules can vary based on the crane model and usage intensity.

What are the differences between a semi-gantry and a full gantry crane?

A semi-gantry crane has one side running on a ground-level rail with the other side elevated on a runway, which is typically mounted on a wall or column structure. A full gantry crane has legs on both sides running typically on ground-level rails, offering more stability and lifting capacity.

How long does it typically take to install a 10 Ton Gantry Crane?

Installation time can vary greatly depending on the crane’s complexity and the preparedness of the installation site. Simple cranes might take a few hours, while more complex systems could require several days to set up properly.

Can a 10 Ton Gantry Crane operate outdoors?

Yes, many gantry cranes are designed for both indoor and outdoor use. For outdoor applications, cranes are equipped with features to withstand various weather conditions, including corrosion-resistant finishes and more robust electrical components.

Where can I purchase a 10 Ton Gantry Crane?

10 Ton Gantry Cranes can be purchased from manufacturers specializing in lifting equipment, industrial machinery suppliers, or through direct orders with customization options to meet specific operational needs.

These FAQs cover key aspects of 10 Ton Gantry Cranes, providing essential information for potential buyers and operators to ensure they understand their options and the operational considerations associated with these cranes.