Here are the top frequently asked questions (FAQs) about 2-ton jib cranes, providing essential information for potential users and buyers:

1. What is a 2-ton jib crane?

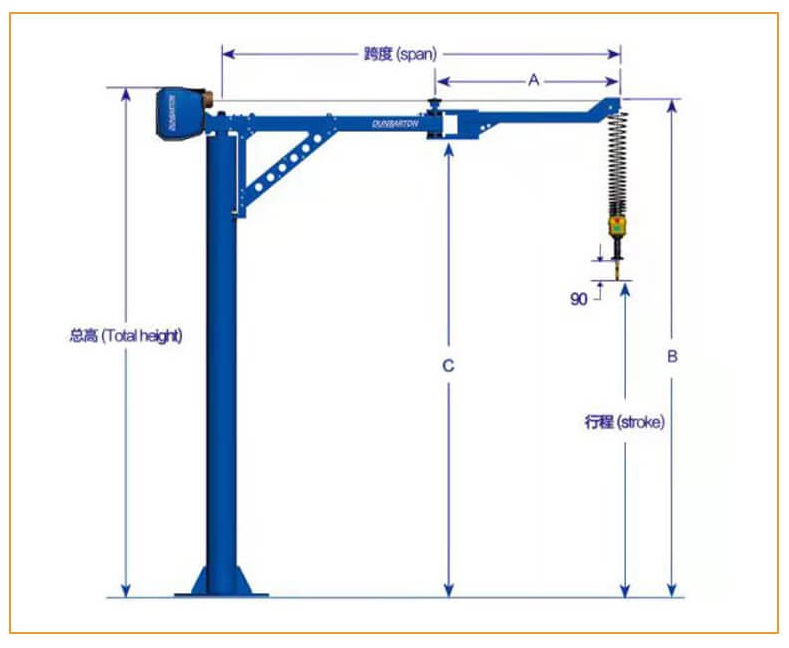

A 2-ton jib crane is a type of lifting equipment designed to lift and move loads up to 2 tons (4,000 pounds). It typically consists of a horizontal jib (boom) attached to a vertical support that allows the jib to swing in a circular area.

2. What are the different types of 2-ton jib cranes available?

There are several types including wall-mounted, free-standing, column-mounted, articulating, mast-type, and portable jib cranes. Each type serves different operational needs and space requirements.

3. Where can a 2-ton jib crane be used?

These cranes are versatile and can be used in various settings such as manufacturing plants, automotive repair shops, warehouses, construction sites, and anywhere heavy lifting is required within a confined area.

4. How much space is required to install a 2-ton jib crane?

The required space depends on the type of crane. Wall-mounted cranes need wall space and sufficient clearance to rotate, while free-standing cranes require ground space for a stable base. Always ensure there is enough clearance for the crane’s full range of motion.

5. Can a 2-ton jib crane be customized?

Yes, customization options include adjustable lengths, heights, slew angles, hoist types (electric, manual, or pneumatic), and control mechanisms (handle or wireless remote control). This allows the crane to be tailored to specific operational requirements.

6. What safety features should be considered when using a 2-ton jib crane?

Safety features to consider include overload protection, emergency stop functions, limit switches, and secure hoist mechanisms. Regular maintenance and safety inspections are crucial to ensure safe operation.

7. What is the typical lifespan of a 2-ton jib crane?

With proper maintenance and care, a 2-ton jib crane can last for many years. The longevity of the crane largely depends on its usage frequency, environmental conditions, and adherence to maintenance schedules.

8. Are there any specific maintenance tips for a 2-ton jib crane?

Regular lubrication of moving parts, routine checks of the hoist and cables for wear and tear, and structural inspections are essential. Following the manufacturer’s maintenance guide will help ensure long-term reliability and safety.

9. What training is required to operate a 2-ton jib crane?

Operators should be trained in proper lifting techniques, crane controls, safety precautions, and emergency procedures. Certification may be required in some jurisdictions.

10. How do I choose the right 2-ton jib crane for my needs?

Consider the type of applications, available space, required range of movement, and specific lifting tasks. Consulting with a crane specialist or manufacturer can also provide guidance based on your specific requirements.

These FAQs cover the basic knowledge needed to understand and effectively utilize a 2-ton jib crane in various industrial environments.