Here are some frequently asked questions (FAQs) about 3 Ton Gantry Cranes to help clarify common inquiries and considerations for those interested in this type of lifting equipment:

What is a 3 Ton Gantry Crane used for?

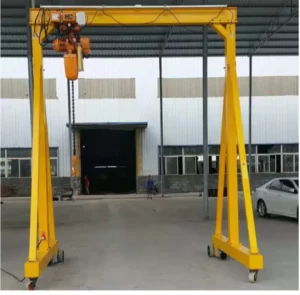

A 3 Ton Gantry Crane is commonly utilized in various industrial settings for lifting and moving loads up to 3 tons. It is ideal for tasks in manufacturing plants, warehouses, workshops, and more, where heavy lifting is required but not exceeding three tons.

Can the height of a 3 Ton Gantry Crane be adjusted?

Yes, adjustable models are available that allow you to change the crane’s height to suit different lifting tasks. This feature is particularly useful in facilities with varied operational needs or ceiling heights.

Are 3 Ton Gantry Cranes portable?

Many 3 Ton Gantry Cranes are designed with portability in mind, equipped with wheels or casters that allow them to be moved easily across a facility. This is especially useful in multi-functional spaces where the crane needs to be relocated frequently.

What are the benefits of a motorized 3 Ton Gantry Crane?

Motorized gantry cranes include features that automate the movement of the hoist and trolley, which increases operational efficiency, reduces the physical strain on operators, and enhances safety by minimizing the risk of manual handling errors.

How do I maintain a 3 Ton Gantry Crane?

Regular maintenance should include checking and lubricating moving parts, inspecting structural components for signs of wear or damage, and ensuring all safety devices are functioning properly. Maintenance schedules can vary based on the crane’s usage and manufacturer’s recommendations.

What safety features should a 3 Ton Gantry Crane have?

Key safety features include overload protection, emergency stop buttons, limit switches to prevent the crane from moving beyond designated boundaries, and anti-collision devices to prevent accidental contact with other equipment or structures.

Can a 3 Ton Gantry Crane be used outdoors?

Some 3 Ton Gantry Cranes are suitable for outdoor use, but it is important to choose a model specifically designed for exterior conditions, which may include features like weather-resistant paint and components that are protected against corrosion.

What are the differences between a fixed and adjustable 3 Ton Gantry Crane?

A fixed gantry crane has a set height and span and is typically more stable, while an adjustable gantry crane offers the flexibility to change the height and/or span, making it adaptable to various tasks and spaces.

How much space is required to operate a 3 Ton Gantry Crane effectively?

The required operational space depends on the crane’s span and the size of the area where the crane will be used. Ensure there is ample space around the crane for safe operation and maneuverability.

Where can I purchase a 3 Ton Gantry Crane?

3 Ton Gantry Cranes can be purchased from manufacturers specializing in lifting equipment, through industrial machinery suppliers, or customized directly from providers that offer specific design adaptations to meet unique operational requirements.

These FAQs cover the essential information for potential buyers and users, ensuring they are well-informed about the capabilities and considerations associated with 3 Ton Gantry Cranes.