telescoping gantry crane Safety Certifications

Telescoping gantry cranes are essential for various industrial applications, providing the flexibility to lift and transport heavy loads. To ensure safety and reliability, these cranes are subject to multiple safety certifications and standards.

1. OSHA (Occupational Safety and Health Administration): OSHA sets forth guidelines and regulations in the U.S. for workplace safety, including the use of gantry cranes. Compliance with OSHA standards ensures that the crane operates safely and minimizes risks to workers.

2. ASME B30.17 (American Society of Mechanical Engineers): This standard, part of the ASME B30 series, specifically addresses overhead and gantry cranes. It covers the design, construction, installation, inspection, and testing requirements. Adherence to ASME B30.17 ensures robust safety and operational integrity.

3. ISO 9001 (International Organization for Standardization): ISO 9001 certification ensures that the manufacturing processes of the crane meet international standards for quality management systems (QMS). This improves the overall safety and reliability of the crane.

4. CE Marking (Conformité Européenne): For cranes sold in the European Economic Area, CE marking is mandatory. It signifies that the product complies with the essential health, safety, and environmental requirements as outlined in applicable European Directives.

5. EN 14492-2: This European standard outlines the safety requirements for power-driven hoists used for cranes. Compliance ensures the safety of hoisting operations, which is critical for the overall safety of a telescoping gantry crane.

6. CSA (Canadian Standards Association): For cranes used in Canada, CSA standards cover various safety aspects, including electrical, structural, and mechanical components. Meeting CSA standards ensures safe operation in accordance with Canadian regulations.

In summary, compliance with these certifications and standards is critical for the safe operation and durability of telescoping gantry cranes. This ensures not only regulatory compliance but also significantly mitigates the risk of accidents and operational failures.

List Reference Technical Parameters of “telescoping gantry crane”

A telescoping gantry crane is a mobile and versatile lifting system used in various industries, including shipping, manufacturing, and construction. Here are key reference technical parameters to consider:

1. Load Capacity:

– Rated Load: The maximum load the crane can safely lift, ranging from a few tons to several hundred tons depending on the model.

2. Span Length:

– The horizontal distance between the runway rails or supporting structures, usually adjustable within certain limits.

3. Lifting Height:

– Maximum vertical distance the hook can travel, critical for applications requiring different elevations.

4. Telescoping Mechanism:

– Number of Telescoping Units: Involves multiple nested sections that extend to increase the lifting height.

– Extension Range: The total amount of height adjustment provided by the telescoping sections.

5. Power Source:

– Electric, diesel, or manual operation, depending on the crane’s application and location.

6. Travel Speed:

– Hoist Speed: The speed at which the hoist can lift or lower a load.

– Trolley Speed: The speed at which the hoisting mechanism travels horizontally along the beam.

– Crane Travel Speed: The speed at which the entire crane moves along the fixed path or tracks.

7. Control Systems:

– Manual control, wired remote control, or wireless remote control options.

8. Material and Construction:

– Typically constructed from high-strength steel to handle the stress and loads.

– Corrosion-resistant finishes for durability and longevity in harsh environments.

9. Safety Features:

– Overload protection, emergency stop functions, anti-collision systems, and limit switches to prevent over-travel.

10. Mobility:

– Wheel configurations: Can be rubber-tired or track-mounted.

– Steering Mechanism: Swivel casters or fixed direction, impacting maneuverability.

11. Compliance Standards:

– Adherence to industry standards and regulations such as ANSI, ASME, and OSHA for safety and performance.

These parameters ensure the safe, efficient, and reliable operation of telescoping gantry cranes tailored to specific lifting needs.

List Product features of “telescoping gantry crane”

A telescoping gantry crane is a versatile and adjustable lifting solution commonly used in various industrial and construction applications. Here are some of its key features:

1. Adjustable Height: The telescoping feature allows the crane to extend and retract its legs and beam, accommodating different heights and lifting requirements.

2. Mobility: Many telescoping gantry cranes come with caster wheels, enabling easy movement and relocation, even with loads. Some models include locking mechanisms for stability during lifting operations.

3. Capacity: These cranes are available in a range of lifting capacities, typically from a few hundred kilograms to multiple tons, catering to different industrial needs.

4. Durability: Constructed from high-strength steel or aluminum, these cranes are designed to withstand heavy use and harsh environmental conditions.

5. Ease of Assembly: Most models feature a modular design that allows for quick assembly and disassembly, making them ideal for dynamic work environments where equipment needs to be frequently moved.

6. Horizontal Beam Adjustment: Some models offer adjustable span lengths, providing flexibility to handle different loads and workspace constraints.

7. Manual or Motorized Operation: Depending on the model, gantry cranes can be operated manually or equipped with electric motors for easier and more efficient lifting and positioning of loads.

8. Safety Features: Many telescoping gantry cranes include safety mechanisms such as overload protection, brake systems, and precision controls to ensure safe operation.

9. Compact Storage: The collapsible design allows for compact storage when the crane is not in use, saving valuable space in the work area.

10. Customization: Available with various accessories like hoists, trolleys, and specialized lifting devices, allowing for customized setups tailored to specific tasks.

11. Compliance: Typically designed to meet industry standards and regulations, ensuring reliability and safety in professional environments.

These features make telescoping gantry cranes an ideal choice for many material handling tasks, offering flexibility, ease of use, and robust performance.

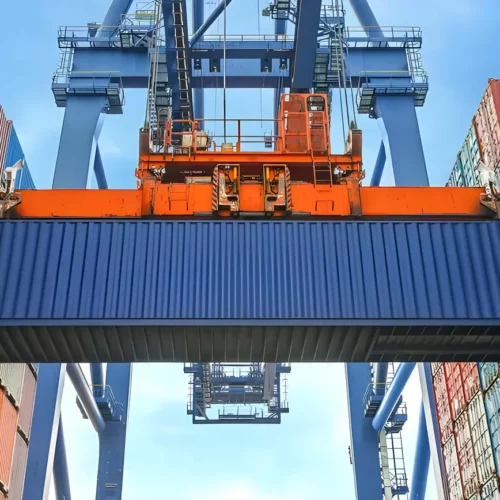

List Application of “telescoping gantry crane”

A telescoping gantry crane is a versatile lifting device characterized by its adjustable height and extendable boom, making it suitable for various applications across different industries. Here are some of its primary applications:

1. Warehousing and Logistics:

– Loading and Unloading: Facilitates the transfer of heavy materials in and out of storage areas or transport vehicles.

– Inventory Management: Efficiently moves goods within warehouses, optimizing space and organization.

2. Construction:

– Material Handling: Lifts and positions construction materials like steel beams, pipes, and concrete sections on sites with restricted space.

– Assembly Work: Assists in the assembly and installation of large structural components.

3. Manufacturing:

– Production Lines: Enhances the efficiency of production lines by moving heavy parts or finished products between stations.

– Maintenance: Plays a crucial role in the maintenance and repair of large machinery by providing accessibility to various parts.

4. Shipbuilding and Maritime:

– Dockside Operations: Manages the loading and unloading of ship parts and cargo, aiding in the construction and repair of vessels.

– Container Handling: Moves shipping containers in and out of dock areas, often where conventional cranes cannot reach.

5. Automotive Industry:

– Engine Lifting: Used for lifting engines and other heavy components during vehicle assembly or repair.

– Parts Handling: Moves large, heavy automotive parts around manufacturing facilities.

6. Aerospace:

– Aircraft Assembly: Assists in positioning large aircraft components accurately during assembly.

– Maintenance: Facilitates access to different parts of aircraft for repair and maintenance work.

7. Mining:

– Material Transport: Moves heavy mining equipment and ore, particularly in confined spaces or varying terrain.

– Installation and Maintenance: Helps with the setup and maintenance of mining infrastructure.

8. Event and Staging:

– Stage Construction: Lifts and positions heavy stage elements, lighting rigs, and sound equipment for concerts and events.

The telescoping gantry crane’s adaptability and mobility make it invaluable across these diverse sectors, enhancing operational efficiency and safety.

List Various Types of “telescoping gantry crane”

Telescoping gantry cranes are versatile lifting machines that combine the mobility of standard gantry cranes with the added functionality of telescoping mechanisms. Here are various types of telescoping gantry cranes:

1. Portable Telescoping Gantry Cranes:

– Manual Portable Cranes:

Operated manually to adjust height and span, typically used for light-duty applications.

– Electric Portable Cranes:

Electrically powered for telescoping adjustments, increasing efficiency for medium-duty applications.

2. Heavy-Duty Telescoping Gantry Cranes:

– Motorized Gantry Cranes:

Powered by electric or hydraulic systems, suitable for heavy-duty industrial applications where frequent adjustments are necessary.

– Double-Girder Gantry Cranes:

Feature two parallel girders for extra stability and heavy lifting capabilities, often seen in shipyards and large-scale construction sites.

3. Adjustable Telescoping Gantry Cranes:

– Adjustable Height Cranes:

Designed to provide varying lifting heights, often used in environments where the crane needs to clear obstacles or fit through doorways with different height requirements.

– Adjustable Span Cranes:

Allow the operator to modify the width of the span to accommodate different sizes of loads and operating space.

4. Aluminum Telescoping Gantry Cranes:

– Lightweight Aluminum Cranes:

Made of aluminum for ease of transport and assembly, ideal for applications requiring frequent relocation such as maintenance and assembly operations.

– Mobile Aluminum Cranes:

Feature wheels for easy mobility and are suitable for use in varied environments like factories or outdoor sites.

Each type of telescoping gantry crane offers unique benefits, making them suitable for different applications and operational requirements. Choosing the correct type involves considering factors such as load capacity, environment, and mobility needs.

telescoping gantry crane Accessories Upgrades and Custom Manufacturing Options

Telescoping gantry cranes are a versatile lifting solution for a variety of industrial applications. To maximize their functionality and efficiency, several accessories, upgrades, and custom manufacturing options are available.

Accessories:

1. Electric Hoists: Enhance lifting capabilities with electric hoists that offer different capacities and speeds.

2. Cable Management Systems: Ensure smooth and safe operation with festoon systems or retractable cable reels.

3. Safety Features: Equip your crane with limit switches, overload sensors, and emergency stop systems for enhanced safety.

4. Radio Remote Controls: Improve operator convenience and safety with wireless remote control options.

5. Trolleys: Choose from manual, electric, or air-powered trolleys for seamless load movement.

Upgrades:

1. Motorized Travel Kits: Convert a manual gantry crane to an electric one for easier and faster movement.

2. Adjustable Height Kits: Provide flexibility to your operations by allowing the gantry height to adjust according to the task at hand.

3. Weatherproofing: Upgrade to weather-resistant materials and coatings for cranes used in outdoor settings.

4. Anti-Collision Devices: Incorporate anti-collision systems to prevent accidents and damage when multiple cranes operate in close proximity.

5. Load Display Systems: Install load cells and digital displays to monitor the weight of lifted items in real-time.

Custom Manufacturing Options:

1. Custom Dimensions: Tailor the size of the gantry crane to meet specific workspace requirements, including custom height, width, and span.

2. Material Choices: Select from various materials like aluminum, steel, or stainless steel, depending on the operational environment.

3. Specialized Wheels: Opt for wheels designed for specific surfaces, such as pneumatic tires for uneven terrain or V-groove wheels for track operations.

4. Color Customization: Match the crane’s color to company branding or for improved visibility.

5. Heavy-Duty Models: For demanding applications, custom heavy-duty cranes can be designed to handle greater capacities and tougher environments.

Choosing the right accessories, upgrades, and custom options can significantly enhance the performance and lifespan of a telescoping gantry crane, catering to the unique needs of any industrial setting.

List Quality Control and The Manufacturing Process of “telescoping gantry crane”

Quality Control of Telescoping Gantry Crane

1. Material Inspection: Verify the quality of raw materials, such as steel and other metals, through tensile strength tests and composition analysis.

2. Dimensional Accuracy: Use precision tools to measure and ensure components meet design specifications.

3. Welding Quality: Perform non-destructive tests like ultrasonic or magnetic particle examination to check for welding defects.

4. Load Testing: Perform static and dynamic load tests to confirm the crane can handle specified weight capacities.

5. Component Verification: Ensure all mechanical and electrical components function correctly.

6. Paint and Coating Inspection: Check for uniform application to prevent corrosion and ensure longevity.

7. Final Assembly Check: Conduct a comprehensive review to ensure all parts fit, and the system operates smoothly.

8. Operational Testing: Run the crane through various cycles to assess performance under simulated working conditions.

9. Compliance Certification: Verify the crane meets industry standards (e.g., OSHA, ISO) for safety and performance.

Manufacturing Process of Telescoping Gantry Crane

1. Design and Planning: Engineers create detailed blueprints and plans, incorporating customer specifications and industry standards.

2. Material Procurement: Source high-quality materials and components required for the crane.

3. Cutting and Shaping: Use tools like plasma cutters and CNC machines to shape raw materials into required components.

4. Welding and Assembly: Weld parts together and assemble sub-units such as the gantry legs and telescoping mechanism.

5. Machining: Perform precision machining on critical parts to ensure dimensional accuracy and proper fit.

6. Surface Treatment: Apply coatings or paint to protect against corrosion.

7. Assembly: Integrate mechanical and electrical components, ensuring all parts fit and function correctly.

8. Calibration and Adjustment: Calibrate the telescoping mechanism and make necessary adjustments for smooth operation.

9. Testing and Inspection: Conduct rigorous quality control tests and inspections to confirm the crane meets all specifications and safety standards.

10. Packaging and Shipping: Carefully package the crane and arrange for delivery to the client’s site.

Through these meticulous quality control measures and a structured manufacturing process, high reliability and performance of the telescoping gantry crane are ensured.

How to use “telescoping gantry crane”

A telescoping gantry crane is a versatile lifting device used to move and position heavy loads. Here is a step-by-step guide on how to use it efficiently:

1. Site Preparation:

– Clear the area where the crane will operate to ensure smooth movement.

– Ensure the ground is level and stable to prevent tilting or accidents.

2. Inspection:

– Inspect the crane for any visible damage or wear.

– Check all safety features, including emergency stop buttons, limit switches, and harnesses.

3. Setup:

– Position the crane directly over the load to minimize horizontal movement.

– Adjust the telescoping legs to the required height, ensuring they are securely locked.

4. Rigging the Load:

– Use appropriate slings or lifting devices for the load.

– Attach the load securely to the crane’s hook, ensuring it is balanced and stable.

5. Lifting:

– Use the crane’s controls to lift the load slowly and steadily.

– Keep the load as close to the ground as possible to reduce swing and increase control.

6. Moving the Load:

– Move the crane slowly and steadily to the desired location.

– Avoid any sudden movements or turns.

7. Lowering the Load:

– Once at the desired location, lower the load gradually.

– Ensure the load is placed securely before detaching the lifting equipment.

8. Post-Operation:

– After completing the task, retract the telescoping legs for compact storage.

– Perform a final inspection to ensure there has been no damage during operation.

9. Safety Precautions:

– Always follow manufacturer’s guidelines for operation.

– Wear appropriate personal protective equipment (PPE) and ensure all personnel are trained.

By adhering to these guidelines, you can operate a telescoping gantry crane safely and effectively.

“telescoping gantry crane” Comparative Analysis

A telescoping gantry crane is a versatile lifting solution commonly used in various industries for material handling tasks. This type of crane is characterized by its extendable structure, allowing it to adjust its height to accommodate different operational requirements. When compared to traditional fixed-height gantry cranes, several advantages and limitations stand out.

1. Versatility:

– Telescoping Gantry Crane: Offers adjustable height, making it suitable for tasks that require varying lifting and lowering capabilities. This makes it ideal for environments where workflows change frequently.

– Fixed-Height Gantry Crane: Limited to a specific height, which can restrict its utility in dynamic work environments but may be sufficient for uniform tasks.

2. Portability:

– Telescoping Gantry Crane: Generally designed for easy movement and relocation within a facility. The telescoping feature can often be adjusted manually or hydraulically, enhancing portability.

– Fixed-Height Gantry Crane: Typically less portable and may require more equipment or labor to move, reducing operational flexibility.

3. Load Capacity:

– Telescoping Gantry Crane: May offer slightly lower load capacities compared to fixed-height cranes due to the additional mechanical complexity required for height adjustment. However, advanced designs can still manage substantial loads.

– Fixed-Height Gantry Crane: Usually can bear higher loads consistently, owing to a simpler and sturdier structure without the need for telescoping mechanisms.

4. Cost Implications:

– Telescoping Gantry Crane: Often more expensive upfront due to the complexity of the design but can yield long-term savings through increased versatility and reduced need for multiple cranes.

– Fixed-Height Gantry Crane: Generally has a lower initial cost but might necessitate additional purchases if varied heights are required for different tasks.

5. Maintenance:

– Telescoping Gantry Crane: More parts and mechanical components mean higher maintenance demands and potential downtimes.

– Fixed-Height Gantry Crane: Simpler design presents fewer maintenance challenges and generally exhibits higher reliability.

In conclusion, the choice between a telescoping gantry crane and a fixed-height gantry crane depends largely on the specific operational needs, budget constraints, and desired flexibility within a given industrial setting.

“telescoping gantry crane” Warranty and Support

Warranty and Support for Telescoping Gantry Crane

Warranty:

Our telescoping gantry cranes come with a comprehensive warranty designed to provide maximum peace of mind. The standard warranty covers parts and labor for one year from the date of purchase. This ensures that any manufacturing defects or issues related to workmanship will be promptly addressed. Extended warranty options are available for additional protection, which can cover up to five years for specific components like the motor and hydraulic systems.

What is Covered:

– Defects in materials or workmanship

– Replacement of malfunctioning parts

– Labor costs associated with repairs

What is Not Covered:

– Normal wear and tear

– Damage caused by misuse, neglect, or unauthorized modifications

– Routine maintenance tasks

Support Services:

We take pride in offering unparalleled support to ensure optimal performance and longevity of your telescoping gantry crane.

Technical Support:

Available 24/7, our technical support team can assist you through phone or email. They are trained to troubleshoot issues effectively and guide you through basic repairs and maintenance.

On-Site Service:

For more complex issues that can’t be resolved remotely, we offer on-site service. Certified technicians will visit your facility to diagnose and fix problems. This service can be scheduled through our customer support hotline.

Training:

We provide comprehensive training programs to ensure your operators are fully versed in the safe and efficient use of the crane. Training can be conducted at your site or online.

Spare Parts:

We maintain a robust inventory of spare parts to minimize downtime. Orders placed by noon can typically be shipped the same day.

Contact Us:

For any warranty claims or support inquiries, please contact our dedicated customer service team at:

– Phone: [Customer Service Number]

– Email: [Customer Service Email]

– Website: [Company Website]

Our commitment to quality and customer satisfaction means you can rely on our telescoping gantry cranes for years to come.

List “telescoping gantry crane” FAQ

Telescoping Gantry Crane FAQ

1. What is a telescoping gantry crane?

A telescoping gantry crane is a type of overhead crane with adjustable height capabilities, allowing it to be set to varying heights to accommodate different lifting requirements. It typically consists of a frame supported by legs with wheels, making it highly portable.

2. How does a telescoping gantry crane work?

The crane features telescoping legs or uprights that can be manually or electrically adjusted. The height adjustment mechanism enables the crane to raise or lower its horizontal beam, or girder, to adapt to different working environments and clearance needs.

3. What are the key advantages of a telescoping gantry crane?

– Versatility: Adjustable height for varied tasks.

– Portability: Wheels allow easy movement across job sites.

– Space-saving: Can be collapsed for storage.

– Cost-effective: Typically less expensive than permanent overhead cranes.

4. Where can telescoping gantry cranes be used?

These cranes are suitable for:

– Warehouses

– Workshops

– Construction sites

– Manufacturing facilities

– Maintenance and repair applications

5. What are the weight capacities for telescoping gantry cranes?

Capacities vary widely based on the design, generally ranging from 500 pounds to several tons. Always consult the manufacturer for specific limits.

6. How can I ensure safety when using a telescoping gantry crane?

– Follow manufacturer guidelines and load limits.

– Conduct regular inspections.

– Ensure the crane is on a level surface before lifting.

– Train operators thoroughly.

7. What materials are telescoping gantry cranes made from?

They are typically made from high-strength steel or aluminum, offering a balance of durability and ease of handling.

8. Are there any maintenance requirements?

Regular maintenance is crucial and includes checking for structural integrity, lubricating moving parts, and ensuring the proper functioning of the height adjustment mechanism.

By understanding these common questions and their answers, users can effectively select and operate telescoping gantry cranes for their specific needs.

Top 10 FAQ with answer about telescoping gantry crane for Buyer Sourcing from China

Sure, here are the top 10 FAQs with answers about sourcing a telescoping gantry crane from China:

1. What is a telescoping gantry crane?

– A telescoping gantry crane is a type of crane with extendable sections that allow for adjustable height and span, making it versatile for various lifting needs.

2. What are the benefits of sourcing from China?

– Chinese manufacturers often offer competitive pricing, diverse options, and advanced technology. Many also provide customization according to specific requirements.

3. How do I ensure quality when sourcing from China?

– Look for ISO certifications, request quality assurance documentation, and conduct factory audits. It’s also wise to procure from reputable brands with positive reviews.

4. What are the common specifications I should consider?

– Focus on load capacity, span length, lifting height, material quality, and application-specific features like mobility and power source (manual or electric).

5. Can I customize the telescoping gantry crane?

– Yes, many Chinese manufacturers offer customizable options to meet your specific operational needs, such as tailored dimensions, additional safety features, and specific power requirements.

6. What is the typical lead time for manufacturing and delivery?

– The lead time can vary based on complexity and customization but generally ranges from 30 to 60 days for manufacturing, plus additional shipping time.

7. How is shipping handled?

– Most manufacturers provide shipping services and can arrange FOB, CIF, or DDP terms. It’s important to clarify this during the negotiation phase.

8. What payment terms are common when sourcing from China?

– Common payment terms include a 30% deposit upfront with the remaining 70% paid before shipment, often secured through a letter of credit or T/T (Telegraphic Transfer).

9. What after-sales support can I expect?

– Reliable manufacturers offer after-sales services such as installation guidance, spare parts, technical support, and sometimes on-site service for complex issues.

10. What certifications should the crane have?

– Ensure the crane has relevant CE, ISO, and other industry-specific certifications that affirm the product meets international safety and quality standards.

By addressing these FAQs, buyers can make informed decisions when sourcing telescoping gantry cranes from China, ensuring they get high-quality equipment tailored to their needs.