diy overhead crane Safety Certifications

When undertaking a DIY overhead crane project, safety is paramount. Here’s a concise guide to essential safety certifications and standards to consider:

1. OSHA Compliance:

– The Occupational Safety and Health Administration (OSHA) sets comprehensive safety regulations for crane operations. Ensure your crane complies with OSHA Standard 1910.179, which governs the design, maintenance, and use of overhead cranes and hoists.

2. ASME Standards:

– The American Society of Mechanical Engineers (ASME) offers guidelines for crane construction and operation. ASME B30.2 covers overhead and gantry cranes, providing foundational safety measures.

3. ANSI Standards:

– The American National Standards Institute (ANSI) collaborates with ASME to develop safety protocols. Ensuring your crane meets ANSI’s sections relating to design, safety, and maintenance is crucial.

4. Load Testing:

– Conduct rigorous load testing to verify the crane’s capability. The load should exceed normal operational weights to confirm structural integrity. Use certified weights and document the testing process meticulously.

5. Professional Inspection and Certification:

– Have a licensed structural engineer or certified crane inspector review your design and construction. Regular inspections help identify potential issues before they become hazardous.

6. Training and Operation:

– Anyone operating the crane should be trained according to OSHA and ASME guidelines. Training should cover all aspects of crane operation, including emergency procedures.

7. Maintenance and Documentation:

– Implement a routine maintenance schedule to keep the crane in optimal condition. Keep detailed records of maintenance and any repairs to ensure compliance and safety.

By adhering to these certifications and standards, you can significantly enhance the safety and reliability of your DIY overhead crane project.

List Reference Technical Parameters of “diy overhead crane”

Sure, here are the reference technical parameters for a DIY (Do-It-Yourself) overhead crane:

1. Load Capacity:

– Max Load: Typically ranges from 0.5 to 2 tons.

2. Span Length:

– Distance between the crane rails: Typically 10 to 20 feet.

3. Lifting Height:

– Max height of lift: Typically up to 15 feet depending on the design and available space.

4. Hoist Type:

– Options: Electric, manual, or pneumatic.

– Hoist Speed: Variable, usually 0.5 to 1.2 m/min for electric hoists.

5. Travel Mechanism:

– Options: Manual push/pull or motorized.

– Travel Speed: For motorized systems, usually around 20 m/min.

6. Power Supply:

– Voltage: Generally 110V or 220V for DIY projects.

– Phase: Single-phase or three-phase depending on the motor type.

7. Control System:

– Type: Pendant control, wireless remote, or wired control.

8. Rails and Track System:

– Material: Typically steel.

– Size: Dependent on load capacity and span length.

9. Structural Support:

– Material: Steel or aluminum beams.

– Beam Size: I-beam or H-beam sizes vary based on load requirements.

10. Safety Features:

– Overload Protection: Ensures crane operates within load limits.

– Limit Switches: Prevents over-travel of the hoist.

– Emergency Stop: Allows immediate halt of operation.

11. Assembly Requirements:

– Tools: Basic hand tools, welding equipment, and possibly a drill press.

– Skills: Moderate mechanical and electrical skills for assembly and installation.

12. Environment:

– Indoor/Outdoor: Generally designed for indoor use, but can be adapted for outdoor settings with weather-proofing measures.

Remember, precise specifications depend on individual project requirements and available materials. Always prioritize safety standards and consult with an engineer if necessary.

List Product features of “diy overhead crane”

The “DIY overhead crane” is a versatile and essential piece of machinery designed to assist in heavy lifting and material handling tasks in workshops, garages, and small industrial settings. Here are some key product features:

1. Construction and Build:

– Durable Materials: Often made of steel or high-strength alloys for robustness and longevity.

– Adjustable Beam: Typically features an adjustable I-beam or gantry design to accommodate various workspace dimensions and lifting requirements.

– Portability: Some models come with wheels or a modular design for easy disassembly and relocation, offering flexibility across different work areas.

2. Lifting Mechanism:

– Hoist Compatibility: Designed to be compatible with various types of hoists, including manual, electric, and chain hoists.

– Load Capacity: Can support a range of load capacities, commonly from 500 lbs to several tons, depending on the design and specifications.

3. Ease of Installation:

– DIY-Friendly: Comes with comprehensive instructions and fewer parts, facilitating straightforward assembly and installation by users with basic tools and mechanical skills.

– Pre-Drilled Holes: Often features pre-drilled mounting holes for easier setup and alignment.

4. Safety Features:

– Safety Locks and Brakes: Equipped with safety mechanisms such as locks and brakes to prevent accidental drops and ensure secure handling of loads.

– Stability Design: Engineered for maximum stability during operation to minimize the risk of tipping or swaying.

5. Customization:

– Modular Components: Easily expandable with additional beams, trolleys, and other accessories to suit specific lifting needs and evolving work environments.

6. Economic Efficiency:

– Cost-Effective: A budget-friendly alternative to professional-grade cranes, offering significant cost savings for small businesses and hobbyists.

– Maintenance: Low maintenance requirements, often featuring simple mechanical systems that are easy to service.

7. Versatility:

– Multiple Applications: Suitable for a variety of tasks, from engine lifting in automotive workshops to material transport in small manufacturing settings.

These features make the DIY overhead crane a practical and efficient solution for lifting and material handling needs in small-scale operations.

List Application of “diy overhead crane”

DIY overhead cranes are versatile lifting devices, commonly used in various settings for handling heavy loads safely and efficiently. Here are some key applications:

1. Home Workshops: DIY enthusiasts and hobbyists use homemade overhead cranes in garages or personal workshops to lift heavy equipment or vehicle parts during repairs or projects, minimizing physical strain.

2. Agriculture: Farmers employ DIY overhead cranes in their barns or equipment sheds to lift and move heavy agricultural machinery, tools, and supplies. This aids in maintenance and saves time compared to manual handling.

3. Small Manufacturing Units: In small-scale manufacturing or fabrication shops, these cranes assist in lifting and positioning heavy raw materials, assembled products, or machinery, enhancing workflow and safety.

4. Warehousing: Small warehouses utilize these cranes for loading and unloading goods, organizing inventory, and moving heavy pallets or containers, thereby increasing efficiency in space utilization and management.

5. Construction Sites: DIY overhead cranes provide a cost-effective lifting solution on small construction projects, helping to move materials and equipment to different levels or specific locations on the site.

6. Art Studios: Artists and sculptors working with large or heavy pieces find DIY cranes useful for maneuvering their work accurately without risking personal injury or damage to the artwork.

7. Boat Maintenance: Enthusiasts maintaining boats at home or in small docks use these cranes to lift engines or other heavy marine components for repairs, installations, or cleaning purposes.

8. Gardening and Landscaping: In large gardens or small-scale nurseries, DIY cranes facilitate the movement of heavy planters, rocks, or large trees, making landscaping tasks more manageable.

Overall, DIY overhead cranes offer a practical, cost-effective solution for lifting and moving heavy objects across various small-scale or personal applications, increasing productivity while ensuring safety.

List Various Types of “diy overhead crane”

Creating a DIY overhead crane can be a cost-effective solution for small workshops, garages, or home projects. There are several types of DIY overhead cranes, each suited for different applications. Below are various types:

1. Fixed Gantry Crane:

– Description: Features a single horizontal beam supported by two vertical legs with wheels.

– Applications: Ideal for lightweight materials and small workspaces.

– Pros: Simple design, easy to construct.

– Cons: Limited to a specific area.

2. Adjustable Gantry Crane:

– Description: Similar to fixed gantry cranes but adjustable in height.

– Applications: Workshops with varying lifting requirements.

– Pros: Versatility in lifting different loads.

– Cons: Slightly more complex to build.

3. Rail-Mounted Gantry Crane:

– Description: Moves on a set of rails.

– Applications: Larger workshops or factory floors.

– Pros: Can cover large areas.

– Cons: More complicated and requires planning for rail installation.

4. Portable Gantry Crane:

– Description: Lightweight, mobile and often collapsible.

– Applications: Temporary or multiple locations.

– Pros: Portability.

– Cons: Limited weight capacity.

5. Jib Crane:

– Description: Consists of a pivoting vertical column with an arm extending outwards.

– Applications: Small workshops requiring localized lifting.

– Pros: Can be wall-mounted or floor-mounted, relatively simple.

– Cons: Limited range of motion compared to gantry cranes.

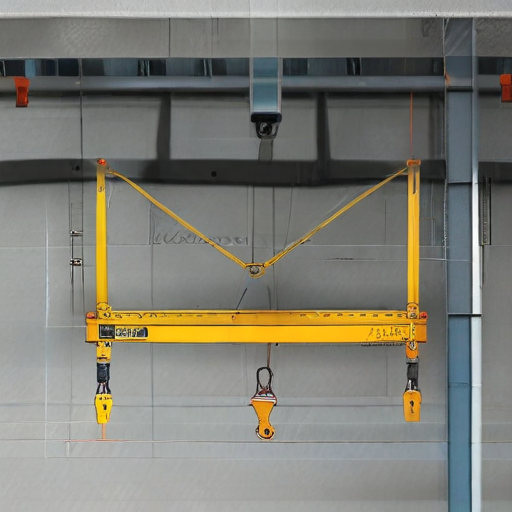

6. Bridge Crane:

– Description: Features a crane bridge that moves on parallel runways.

– Applications: Larger buildings or warehouses.

– Pros: Can handle heavy loads, large workspace coverage.

– Cons: Requires permanent installation and structural support.

7. Engine Hoist:

– Description: Small, portable and usually foldable units designed for automotive work.

– Applications: Home garages for engine lifting.

– Pros: Specifically designed for engine removal and installation.

– Cons: Limited to automotive applications.

Each type has its pros and cons, and the choice depends on your specific needs, space constraints, and the weight of the materials you intend to lift.

diy overhead crane Accessories Upgrades and Custom Manufacturing Options

Creating a DIY overhead crane can be a cost-effective and efficient way to handle heavy materials in your workshop. Upgrading and accessorizing your crane can further enhance its functionality and safety. Here are several key accessories, upgrades, and custom manufacturing options to consider:

1. Trolleys: Invest in high-quality trolleys to enable smooth horizontal movement along the beam. Options include push trolleys for manual operation or electric trolleys for automated movement.

2. Hoists: Choose between manual chain hoists, electric hoists, or hydraulic hoists based on your lifting needs. Ensure the hoist is compatible with your crane’s load capacity.

3. Wireless Remote Control: For enhanced safety and convenience, add a wireless remote control system. This allows you to operate the crane from a safe distance.

4. Limit Switches: Install limit switches to prevent accidental over-travel of the hoist, protecting both the crane and the load.

5. Variable Frequency Drives (VFDs): Adding VFDs can provide smooth starts and stops, reducing wear and tear on the crane’s components and offering more precise control over lifting operations.

6. End Stops and Buffers: Enhance safety by installing end stops and buffers to prevent the trolleys from derailing at the ends of the beam.

7. Structural Reinforcements: Depending on your load requirements, you may need to reinforce the crane’s structural components, such as the beam and supports. Custom-manufactured steel beams or braced supports can ensure stability and durability under heavy loads.

8. Custom Beam Designs: If standard beams don’t meet your needs, consider custom manufacturing options. Custom-fabricated I-beams or box girders can provide tailored strengths and dimensions.

9. Weatherproofing and Corrosion Protection: For outdoor or harsh environments, apply weatherproof coatings and corrosion inhibitors to prolong the crane’s lifespan.

10. Load Indicators: Integrate digital load indicators to monitor the weight being lifted, ensuring it does not exceed the crane’s capacity.

By combining these accessories and upgrades, your DIY overhead crane can become a robust and reliable tool in your material handling arsenal. Ensure all modifications comply with safety standards and guidelines.

List Quality Control and The Manufacturing Process of “diy overhead crane”

Quality Control:

1. Material Inspection: Verify the quality of raw materials such as steel and cables, ensuring they meet specifications.

2. Welding Checks: Inspect welds for defects like cracks or weak spots using non-destructive testing methods.

3. Dimensional Accuracy: Measure all components to ensure they conform to design tolerances.

4. Load Testing: Perform load tests to check the structural integrity of the crane under operational loads.

5. Safety Inspections: Ensure all safety features such as brakes and limit switches are functional.

6. Component Verification: Confirm that motors, controls, and other components meet required standards.

7. Assembly Validation: Double-check assembled units to ensure that all parts are fitted correctly and securely.

8. Final Inspection: Carry out a comprehensive review and testing of the complete crane system before dispatch.

Manufacturing Process:

1. Design and Planning:

– Design Specifications: Create detailed drawings and specifications.

– Material Procurement: Source high-quality materials.

2. Cutting and Shaping:

– Steel Cutting: Use laser or plasma cutting machines to shape steel components.

– Machining: Machine parts to precise dimensions using lathes, mills, and drills.

3. Fabrication:

– Welding: Weld the cut and machined parts into assemblies like the crane bridge, trolley, and hoist.

– Heat Treatment: Treat welded parts to relieve stress and improve strength.

4. Assembly:

– Component Installation: Assemble the primary crane components and install motors, trolleys, and hoists.

– Electrical Wiring: Connect electrical systems, controls, and safety switches.

5. Surface Treatment:

– Painting/Coating: Apply protective coatings to resist corrosion and wear.

6. Quality Control:

– Conduct thorough inspections and tests as described above.

7. Final Assembly:

– Pre-Assembly Check: Ensure all parts are ready and functional.

– Fitting: Assemble the final product with care.

8. Testing:

– Carry out operational and load tests to ensure performance meets safety and operational standards.

9. Shipping:

– Packaging: Securely package the crane and all components for delivery.

– Documentation: Provide manuals and certification documents.

How to use “diy overhead crane”

Using a DIY overhead crane can be a great way to move heavy objects efficiently. Here’s a concise guide:

Materials Needed

1. I-Beam or Rail: Acts as the track.

2. Trolley: Moves along the I-Beam.

3. Hoist: To lift the load.

4. Supports: To hold the I-Beam in place.

5. Fasteners and Tools: Bolts, nuts, wrenches, and drills.

Installation Steps

1. Mount the I-Beam:

– Securely install the I-Beam or rail using robust supports on both ends. Ensure it’s level.

2. Install the Trolley:

– Attach the trolley to the I-Beam so it can move smoothly along the track.

3. Attach the Hoist:

– Connect the hoist to the trolley. Ensure it’s securely fastened and can handle the intended load.

4. Electrical Connection:

– If using an electric hoist, properly connect it to a power source, following safety guidelines.

Operational Steps

1. Pre-Operation Check:

– Inspect the crane for any visible damage.

– Ensure all bolts and nuts are tight.

2. Position the Trolley:

– Move the trolley to the position directly above the load.

3. Connect the Load:

– Securely attach the load to the hoist using appropriate rigging equipment.

4. Lift the Load:

– Gradually operate the hoist to lift the load, ensuring it is balanced.

5. Move the Load:

– Carefully move the trolley along the I-Beam to the desired location.

6. Lower the Load:

– Gradually lower the load using the hoist until it’s safely on the ground.

Safety Tips

– Never exceed the crane’s weight capacity.

– Regularly inspect the crane for wear and tear.

– Always follow manufacturer guidelines for both installation and operation.

Using your DIY overhead crane safely and effectively ensures efficiency and prolongs the equipment’s lifespan.

“diy overhead crane” Comparative Analysis

When considering a DIY overhead crane, several key aspects must be analyzed: cost, complexity, safety, and functionality.

1. Cost: A DIY overhead crane is generally more budget-friendly than commercial models. By sourcing materials locally and using existing tools, costs can be minimized. However, this cost advantage might diminish if specialized equipment or expertise is required for construction.

2. Complexity: Building an overhead crane demands a solid understanding of mechanics and structural design. Commercial cranes come with pre-engineered solutions and user manuals, simplifying the installation. DIY projects, while customizable, require meticulous planning, accurate measurements, welding, and possibly custom machining.

3. Safety: This is arguably the most critical concern. Commercial cranes adhere to strict industrial standards and regulations, ensuring maximum safety. DIY cranes, if inadequately designed or improperly assembled, could pose significant risks, including structural failure or accidents. Ensuring dynamics, load distribution, and material strength is paramount in DIY projects.

4. Functionality: Purchased overhead cranes offer advanced features like automated control systems, adjustable lifting capabilities, and robust load capacities, often backed by warranties and professional support. DIY cranes can be customized to specific needs but may lack the precision and reliability found in commercial models. Properly designed, however, they can effectively accomplish basic lifting tasks.

In summary, DIY overhead cranes provide a cost-effective, customizable solution for specific lifting needs but at the expense of increased complexity and potential safety concerns. For those with proper skills and tools, they offer an intriguing challenge paired with satisfaction. Conversely, commercial cranes ensure higher reliability, advanced features, and adherence to safety standards, albeit at a higher cost.

“diy overhead crane” Warranty and Support

Warranty and Support for DIY Overhead Crane

When considering a DIY overhead crane, understanding the warranty and support options available is crucial for ensuring both safety and longevity of the equipment. Typically, DIY overhead crane kits come with a manufacturer’s warranty that can range from 1 to 5 years, depending on the brand and model. This warranty generally covers defects in materials and workmanship under normal use conditions. Be sure to read the warranty documentation carefully to understand what is and isn’t covered.

Warranty Inclusions:

1. Structural Components: Coverage often includes the beams, rails, and other main structural elements.

2. Electrical Parts: Motors, controllers, and wiring may also be included but often have a shorter warranty period.

3. Wear and Tear: Limitations typically exist around consumable parts subject to normal wear and tear, like wheels and brake pads.

Support Services:

1. Technical Support: Manufacturers usually offer comprehensive technical support to assist in the installation and maintenance of the crane. This can include step-by-step guides, video tutorials, and troubleshooting tips.

2. Customer Service: Most brands provide a customer service hotline or email service where you can get answers to your queries and report any problems.

3. Replacement Parts: Access to genuine replacement parts is crucial. Many manufacturers provide a streamlined process for ordering parts covered under warranty or for purchase.

4. Service Technicians: Some suppliers offer the option to have certified technicians assist with installation or repair, either remotely or on-site.

For a seamless experience, choose a reputable brand known for reliable customer service and comprehensive warranty coverage. Always register your product with the manufacturer, if required, to activate the warranty and ensure that you’re eligible for all support services. Your DIY overhead crane is an investment, so ensuring robust warranty and support options can save you time, money, and potential headaches down the road.

List “diy overhead crane” FAQ

DIY Overhead Crane FAQ

1. What is a DIY Overhead Crane?

A DIY overhead crane is a lifting system that you can build yourself, typically using readily available materials and tools. It is used to move heavy objects across a workspace efficiently.

2. What are the key components?

– Girder/Beam: The main horizontal support.

– End Trucks: Wheels and motors that move the crane along a path.

– Hoist: The mechanism that lifts and lowers the load.

– Trolley: Carries the hoist along the beam.

– Supporting Structure: Columns or frameworks holding up the beam.

3. What materials are typically used?

– Metal beams (steel or aluminum)

– Heavy-duty casters or wheels

– Electric or manual hoists

– Fasteners, welding supplies, and other construction materials

4. What are the common weight capacities?

DIY cranes can range from a few hundred pounds to several tons, depending on materials used and structural integrity. Always ensure your construction meets safety loads well above your maximum intended use.

5. Do I need special tools?

Basic hand tools, power drills, wrenches, and possibly a welding kit are required. More complex builds might need specialized machinery like a metal saw or lathe.

6. How do I ensure safety?

– Use high-quality, rated components.

– Follow engineering guidelines for load capacities.

– Perform regular inspections and maintenance.

– Never overload the crane.

– Use proper rigging techniques and safety gear.

7. Can I automate it?

Yes, automation can be added using electric hoists, remote controls, and programmable logic controllers (PLCs) for more advanced operations.

8. Are there legal considerations?

Check local regulations, building codes, and safety standards before constructing and operating an overhead crane.

9. What skills do I need?

Basic construction knowledge, mechanical aptitude, and a good understanding of physics and engineering principles are highly beneficial.

10. Where can I find plans or kits?

Online DIY forums, hardware stores, and suppliers specializing in industrial equipment often provide blueprints, kits, or parts for building overhead cranes.

Top 10 FAQ with answer about diy overhead crane for Buyer Sourcing from China

Certainly! Here are the top 10 frequently asked questions (FAQ) about sourcing DIY overhead cranes from China, along with their concise answers:

1. What are the main types of DIY overhead cranes available from China?

– Common types include single girder, double girder, top-running, and under-running cranes. Each type has unique features to suit specific applications and load capacities.

2. What is the typical lead time for manufacturing and delivery?

– Lead times vary but generally, it takes 30-60 days for manufacturing, depending on customization needs and order quantity. Shipping times will depend on your location.

3. How do I ensure the quality of the overhead crane?

– Choose suppliers with ISO certification and check if they comply with international standards like CE or ANSI. Request for inspection reports, material certificates, and references from previous customers.

4. What are the import duties and taxes when sourcing from China?

– Import duties and taxes vary by country. Consult your local customs office or a customs broker for specific information related to your location.

5. Are there any hidden costs involved?

– Apart from the product cost, consider shipping, customs fees, insurance, and possible installation costs. Confirm all expenses with the supplier upfront.

6. Can I customize the crane to meet specific requirements?

– Yes, many Chinese manufacturers offer customization options such as specific load capacities, dimensions, and features to meet your specific needs.

7. What warranty and after-sales services are provided?

– Warranties typically range from 1 to 2 years. Ensure the supplier offers after-sales support, which may include spare parts, technical assistance, and onsite service if necessary.

8. What payment methods are accepted?

– Common payment methods include T/T (Telegraphic Transfer), L/C (Letter of Credit), and sometimes, Western Union. Negotiate favorable terms and ensure secure transactions.

9. What documents are required for importing an overhead crane?

– Necessary documents generally include a commercial invoice, packing list, bill of lading, and certificate of origin. Additional documents may be required depending on your country’s regulations.

10. How can I verify the credibility of a Chinese supplier?

– Check for a valid business license, review online ratings and customer feedback, conduct a factory audit if feasible, and use third-party verification services like Alibaba’s Trade Assurance.

By addressing these frequently asked questions, buyers can make more informed decisions when sourcing DIY overhead cranes from China.