free standing jib crane Safety Certifications

Free-standing jib cranes are essential for various lifting and material handling tasks. To ensure safety and compliance, several safety certifications and standards must be met:

1. ANSI/ASME B30.11 – This standard covers the safety requirements for monorails and underhung cranes, and it includes guidelines for the design, construction, installation, inspection, and operation of jib cranes.

2. OSHA (Occupational Safety and Health Administration) – Regulations such as OSHA 1910.179 and OSHA 1910.180 detail the safety standards for overhead and gantry cranes and derricks, which can apply to jib cranes. Compliance with OSHA standards helps in minimizing workplace accidents.

3. CMAA (Crane Manufacturers Association of America) Specification No. 74 – This sets performance standards for jib cranes, including the duty cycle and load ratings, ensuring that they are safe for intended applications.

4. ISO 9001 – While not a direct safety certification, manufacturers certified under this quality management standard are more likely to produce reliable and safe equipment.

5. FEM (Fédération Européenne de la Manutention) Standards – These European standards provide guidelines on the design and safety requirements for various types of cranes, including jib cranes.

6. EN 14492-1 – This European standard specifies the safety requirements for power-driven hoists and jib cranes, ensuring they meet stringent safety norms.

7. Regular Maintenance and Inspections – Regardless of certifications, jib cranes should undergo regular maintenance and inspections as dictated by the standards above. This ensures that the crane remains in safe working condition.

8. Load Testing – Periodic load testing should be conducted to verify the crane’s capacity and performance under load conditions as per ANSI/ASME B30.11 and other relevant standards.

Ensure that your jib crane provider complies with these certifications and standards to maintain a safe working environment.

List Reference Technical Parameters of “free standing jib crane”

A free-standing jib crane is a versatile piece of material handling equipment used in various industries. Below are the key reference technical parameters:

1. Load Capacity: Typically ranges from 0.5 to 15 tons, indicating the maximum weight the crane can handle.

2. Span Length: The horizontal distance from the center of the column to the end of the jib, generally between 5 to 30 feet.

3. Height Under Boom: Refers to the vertical distance from the floor to the underside of the jib arm, varying from 8 to 20 feet.

4. Rotation: Allows for the movement of the jib arm, with standard options being 180°, 270°, or 360°, depending on the design.

5. Hoist Type: Options include manual, electric, or pneumatic hoists, affecting the crane’s lifting mechanism and operation speed.

6. Lift Speed: The rate at which the hoist can raise or lower the load, typically measured in feet per minute (FPM).

7. Travel Speed: Relates to the trolley’s movement along the jib arm, also measured in feet per minute.

8. Mounting Style: Includes base-plate mounted, which is bolted to the floor, or insert-mount, embedded in concrete foundations.

9. Boom Fabrication: Typically constructed from I-beam or enclosed track to provide strength and durability against bending and twisting.

10. Column Construction: Usually a round or square steel tubular design that provides robust support for the jib arm.

11. Duty Cycle: Defines the frequency and duration the crane can be used, categorized into light, medium, heavy, or continuous duty.

12. Power Supply: Voltage and phase (single or three-phase), commonly 230V/1P or 460V/3P.

13. Control Method: Options include pendant controls, radio remote controls, or push-button stations for operating the crane functions.

These parameters ensure that the free-standing jib crane is specified correctly to match operational requirements and constraints.

List Product features of “free standing jib crane”

Product Features of a Free Standing Jib Crane

1. Robust Construction: Free standing jib cranes are typically made from high-strength steel, ensuring durability and longevity in industrial environments.

2. High Load Capacity: These cranes are designed to lift and transport heavy loads, with capacities typically ranging from 1 ton to 5 tons, and can go higher depending on the design.

3. 360-Degree Rotation: Many models offer a full 360-degree rotation, providing flexibility in maneuvering and positioning loads within the working area.

4. Adjustable Boom Length: The boom, or horizontal arm, is often adjustable in length, allowing for customization based on specific spatial requirements and lifting needs.

5. Ease of Installation: Free standing jib cranes can be installed on any flat, stable surface, without the need for an existing structure for support. This makes them versatile for various applications and easy to relocate if necessary.

6. Efficient Operation: Equipped with manual or motorized trolleys and hoists, these cranes facilitate smooth and efficient material handling operations.

7. Safety Features: Common safety features include overload protection, emergency stop functions, and secure anchoring systems to ensure safe and accident-free operations.

8. Versatility: Ideal for both indoor and outdoor use, suitable for diverse environments such as warehouses, manufacturing plants, and construction sites.

9. Low Maintenance: Designed for minimal upkeep, these cranes typically require only regular inspections and lubrication, contributing to lower operating costs.

10. Customizable: Options for height, boom length, and accessories such as tool balancers, electronic controls, and specialized grippers to tailor the crane to specific operational needs.

11. Ergonomic Design: Enhances worker productivity and reduces the risk of injury by allowing easy lifting and precise placement of heavy items.

12. Compliance with Standards: Built to meet or exceed industry standards and regulations, ensuring reliability and safety in operations.

List Various Types of “free standing jib crane”

A free-standing jib crane is a versatile material handling device that provides 360-degree rotation and can be installed almost anywhere in a facility. There are various types to suit different needs and applications:

1. Base Mounted Jib Cranes: These are the most common, featuring a mast that is bolted to a concrete floor. They’re ideal for high-capacity lifting and frequent use.

2. Foundationless Jib Cranes: Designed for light to moderate lifting capacities, these cranes do not require a reinforced concrete foundation, making them easier and more cost-effective to install.

3. Articulating Jib Cranes: These models have two rotating arms, allowing the crane to reach around obstacles and into confined spaces. They are used for precise positioning of loads and complex workstations.

4. Drop Cantilever Jib Cranes: These versions have a unique design where the arm is mounted lower than the mast height, allowing them to provide lifting solutions in low-clearance environments.

5. Freestanding I-Beam Jib Cranes: Typically, these cranes utilize I-beam construction for the mast and boom, providing robust lifting capabilities suitable for heavy-duty applications.

6. Freestanding Mast Type Jib Cranes: Instead of being mounted to a wall or column, these cranes are supported by a mast that is affixed to the floor with a base plate, allowing flexibility in placement.

7. Portable Freestanding Jib Cranes: These are equipped with a movable base, enabling the crane to be transported to different locations within a facility.

Each type offers specific advantages depending on the application, such as weight capacity, range of motion, and installation requirements. Choosing the right jib crane type ensures optimal performance and efficiency for material handling tasks.

List Application of “free standing jib crane”

A free-standing jib crane is a versatile piece of lifting equipment utilized across various industries. Here are some of its primary applications:

1. Manufacturing and Assembly Lines: Utilized for lifting, moving, and positioning heavy parts and assemblies. It enhances efficiency in workflows by enabling precise placement of materials and components.

2. Warehousing and Storage Facilities: Facilitates the loading and unloading of goods, improving inventory management. Jib cranes help in stacking and organizing heavy items efficiently.

3. Construction Sites: Assists in lifting building materials like steel beams, concrete blocks, and other heavy items. Its mobility and ease of installation make it suitable for temporary construction needs.

4. Automotive Industry: Used for lifting engines, transmissions, and large components during assembly or repair. Jib cranes provide the necessary reach and flexibility for working on various vehicle parts.

5. Maintenance and Repair Operations: Essential for lifting and positioning heavy machinery or equipment for maintenance. They provide support in confined spaces where other lifting equipment might not fit.

6. Shipping and Logistics: Used for loading and unloading shipping containers, pallets, and heavy cargo from trucks and ships. Jib cranes improve the efficiency of cargo handling operations.

7. Mining and Heavy Industries: Helps in moving heavy equipment and materials within mines or industrial setups. Jib cranes endure tough environments and handle substantial weights effectively.

8. Chemical and Pharmaceutical Plants: Assists in handling heavy drums, raw materials, and machinery parts, ensuring safety in the workplace. It helps maintain cleanliness and operational efficiency by reducing manual handling.

9. Aerospace Industry: Utilized for assembling aircraft parts and components, requiring precise and delicate handling. Jib cranes facilitate seamless movement of large, irregularly shaped parts.

10. Marinas and Dockyards: Employed for lifting boats, engines, and other heavy marine equipment. Jib cranes offer the flexibility needed in waterfront environments.

Overall, free-standing jib cranes are indispensable in settings where lifting and precise positioning of heavy items are required, offering improved safety, efficiency, and productivity.

List Buyer Types of “free standing jib crane”

Buyers of free standing jib cranes span various industries and sectors due to their versatility and utility in material handling tasks. Here’s a concise list of buyer types typically interested in acquiring free standing jib cranes:

1. Manufacturing Facilities: These include automotive, aerospace, and electronics manufacturers that use jib cranes for lifting heavy components, assembly line assistance, and moving products through different production stages.

2. Construction Companies: Utilized for handling construction materials, machinery, and tools on-site, especially in areas where portability and ease of setup are crucial.

3. Warehouses and Distribution Centers: Used for loading and unloading goods from trucks, organizing inventory, and moving heavy items with ease within the warehouse environment.

4. Shipyards and Marine Industries: Essential for lifting and placing heavy ship parts, maintenance equipment, and other heavy-duty materials in shipbuilding and repair activities.

5. Mining and Extractive Industries: Employed in handling large mining equipment, minerals, and tools, facilitating safer and more efficient material handling in rugged conditions.

6. Oil and Gas Operations: Used on both offshore and onshore platforms to move heavy pipes, drilling equipment, and other essential tools, enhancing operational efficiency and safety.

7. Utilities and Power Generation: Required for maintenance and installation tasks in power plants, including handling heavy machinery components, turbines, and generators.

8. Fabrication Shops and Metalworking: Utilized for lifting and positioning raw materials, fabricated parts, heavy machinery, and finished products, streamlining workflow and improving safety.

9. Railways and Transportation Hubs: Essential for maintenance of railway cars, handling heavy freight, and ensuring smooth logistical operations.

10. Defense and Aerospace Sectors: Used for moving and assembling intricate components, aircraft parts, and heavy machinery, adhering to stringent safety and precision requirements.

These buyers primarily seek free standing jib cranes to enhance productivity, ensure safety, and streamline material handling operations across diverse and demanding environments.

List “free standing jib crane” Project Types for Different Industries

Sure! Here’s a concise list of “free standing jib crane” project types across different industries:

1. Manufacturing:

– Assembly Line Support: Boost efficiency in assembly lines by swiftly moving parts.

– Machinery Service: Aid in machine maintenance and service tasks.

– Material Handling: Simplify the transfer of heavy materials within the facility.

2. Warehousing and Logistics:

– Loading/Unloading: Facilitate the loading and unloading of trucks and storage racks.

– Inventory Management: Enhance inventory handling by effortlessly moving large goods.

3. Construction:

– Site Preparation: Assist in setting up construction sites by transporting heavy tools and materials.

– Elevated Work Platforms: Support workers in lifting and placing building materials at height.

4. Automotive:

– Engine Assembly: Streamline engine and parts assembly tasks.

– Maintenance and Repair: Provide support for lifting heavy components during vehicle repairs.

5. Aerospace:

– Component Handling: Aid in the precise handling of large and sensitive aerospace parts.

– Assembly and Inspection: Simplify the transportation of components during assembly and inspection stages.

6. Energy:

– Wind Turbine Maintenance: Assist in maintaining and repairing heavy components of wind turbines.

– Oil and Gas: Facilitate the movement of heavy drilling equipment and machinery.

7. Food and Beverage:

– Processing Equipment: Enhance handling of bulky ingredients and processing machinery.

– Packaging: Streamline the movement of packaged goods for storage and distribution.

8. Mining:

– Equipment Handling: Assist in maneuvering large mining equipment and materials.

– Maintenance: Provide support for routine maintenance activities in mining operations.

Incorporating free standing jib cranes in these project types can significantly improve operational efficiency, safety, and productivity across diverse industries.

free standing jib crane Accessories Upgrades and Custom Manufacturing Options

Free-standing jib cranes significantly enhance productivity by allowing lift and transport of materials within a specific radius. To further optimize their functionality, several accessories, upgrades, and custom manufacturing options are available.

Accessories:

1. Electric Hoists: Improve lifting efficiency and reduce manual labor.

2. Variable Speed Controls: Fine-tune load handling and improve precision.

3. Rotational Stops: Restrict boom movement to prevent collisions and enhance safety.

4. Festoon Systems: Manage electrical cables or air hoses to avoid entanglement.

5. Hooks, Grabs, and Magnets: Customizable end-effectors to handle a variety of loads.

Upgrades:

1. Motorized Rotation: Upgrade to motorized systems for smoother and effortless rotation.

2. Increased Load Capacity: Reinforce the crane structure to handle heavier loads, if required.

3. Advanced Control Systems: Integrate smart controls for remote and automated operations.

4. Corrosion-Resistant Materials: Upgrade to stainless steel or coated components for durability in harsh environments.

5. Anti-Sway Technology: Incorporate systems to minimize load sway and enhance precision.

Custom Manufacturing Options:

1. Tailored Boom Lengths and Heights: Match specific operational requirements.

2. Specialized Mounting Bases: Adapt the crane to various floor configurations or mobile bases.

3. Environmental Adaptations: Custom designs for high-temperature or chemically aggressive environments.

4. Safety Enhancements: Additional safety systems like overload protection, emergency stops, and safety enclosures.

5. Design Aesthetics: Color customization and company branding.

These accessories, upgrades, and customization options ensure that free-standing jib cranes meet unique operational needs while maximizing safety, efficiency, and durability.

List Quality Control and The Manufacturing Process of “free standing jib crane”

Quality Control and Manufacturing Process of Free Standing Jib Crane

Manufacturing Process:

1. Design and Engineering:

– Requirements Analysis: Determine load capacity, span, and height.

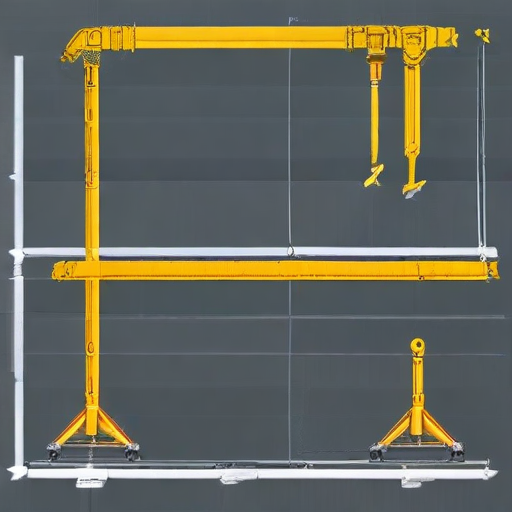

– CAD Modeling: Create detailed 3D models and blueprints.

2. Material Selection:

– Choose high-strength steel and other materials based on load and environmental conditions.

– Procure certified raw materials from trusted suppliers.

3. Cutting and Shaping:

– Use CNC lasers, saws, and plasma cutters to cut steel components to specified shapes and sizes.

– Employ bending machines and rollers for shaping.

4. Welding and Assembly:

– Perform sub-assemblies, such as welding the mast, boom, and base plate.

– Use robotic and manual welding techniques to ensure precision and strength.

5. Machining:

– CNC machines for precise holes and fittings.

– Ensure alignment for rotational and bearing points.

6. Surface Treatment:

– Shot Blasting: Clean and roughen surfaces for better adhesion.

– Painting/Coating: Apply anti-corrosive coatings and paint to protect against environmental factors.

7. Final Assembly:

– Combine all components, ensuring fit and alignment.

– Install electrical systems, if any, like motorized rotation controls.

8. Testing:

– Conduct load and stress tests, operational checks, and safety verifications.

Quality Control:

1. Incoming Material Inspection:

– Verify chemical and physical properties of raw materials.

2. In-Process Inspections:

– Dimensional checks during cutting and machining.

– Non-destructive testing (NDT) for welds and critical parts.

3. Assembly Verification:

– Check alignment and fit during sub-assembly and final assembly.

– Verify fastener torque and proper installation techniques.

4. Surface Quality Control:

– Inspect coating thickness and adhesion.

– Check for uniform application and coverage.

5. Final Testing:

– Load and operational tests to ensure the crane meets design specifications.

– Safety testing including overloading scenarios and emergency stop functions.

6. Documentation:

– Maintain comprehensive records of inspections, tests, and corrective actions.

– Ensure traceability of materials and parts.

How to use “free standing jib crane”

A free-standing jib crane is a versatile and efficient lifting device commonly used in industrial environments. Here’s a step-by-step guide on how to use it:

Setup:

1. Inspect the Crane:

– Before use, perform a visual inspection for any damage or wear.

– Check that all components, such as the boom, column, hoist, and trolley, are secure and in good condition.

2. Prepare the Workspace:

– Ensure the area around the crane is clear of obstructions.

– Verify that the crane can rotate freely without hitting any objects.

Operation:

1. Attach the Load:

– Use appropriate lifting slings or attachments for your load.

– Secure the load to the hoist hook, ensuring it is balanced and stable.

2. Lift the Load:

– Use the hoist controls to slowly lift the load just off the ground.

– Check that the load is stable and securely attached.

3. Move the Load:

– Rotate the jib arm to the desired position by pushing or pulling it. Some jib cranes have motorized rotation.

– Use the trolley controls to position the load horizontally along the jib arm.

4. Lower the Load:

– Once the load is in position, use the hoist controls to slowly lower it to the ground or onto the desired surface.

Safety Precautions:

1. Stay Aware:

– Always be attentive to the crane’s surroundings and where the load is being moved.

2. Do Not Overload:

– Ensure the load does not exceed the crane’s capacity.

3. Use Personal Protective Equipment (PPE):

– Wear appropriate PPE, such as gloves, safety shoes, and a hard hat.

Post-Operation:

1. Secure the Crane:

– After use, ensure the jib crane is in a safe, neutral position.

2. Perform a Final Check:

– Conduct a final check to ensure there is no damage to the crane after use.

By following these steps, you can safely and efficiently use a free-standing jib crane for various lifting and moving tasks.

“free standing jib crane” Comparative Analysis

A free-standing jib crane is a type of overhead lifting device that features a horizontal jib or boom supporting a hoist, which is affixed to a self-supporting, vertical mast anchored to the floor. When considering its implementation, several factors distinguish it from other crane types: versatility, ease-of-installation, load capacity, and operational efficiency.

Versatility: Free-standing jib cranes excel in applications requiring frequent and varied lifting tasks. The boom can rotate 360 degrees, allowing access to a large work area without the need for floor space-consuming tracks or extensive support structures.

Ease of Installation: Unlike wall-mounted or top-running gantry cranes, free-standing jib cranes require less structural support from the facility. This independence simplifies installation and minimizes disruptions, making it particularly advantageous for temporary or evolving work sites.

Load Capacity: Typically, free-standing jib cranes handle loads ranging from 1 to 5 tons, albeit with extreme precision. This load range makes them suitable for assembly lines, warehouses, and maintenance operations. In contrast, gantry cranes or bridge cranes, with their higher load capacities, are preferable for heavier, bulkier materials.

Operational Efficiency: In tight spaces or where overhead clearance is limited, free-standing jib cranes offer significant operational benefits. Their small footprint and high flexibility enable efficient material handling within confined or highly specialized areas, unlike larger overhead cranes that require more headroom and space.

Cost Considerations: While the initial cost of a free-standing jib crane can be competitive, particularly when compared to gantry or bridge cranes, ongoing maintenance and operational costs are generally lower due to fewer complex components and simpler design.

In summary, a free-standing jib crane provides a versatile, easy-to-install, and efficient lifting solution for a variety of applications. Its suitability hinges on the specific needs of the work environment, particularly in facilities where space, flexibility, and moderate lifting capacity are paramount. For heavier loads or broader coverage areas, alternative crane systems like gantry or bridge cranes may offer superior performance.

“free standing jib crane” Warranty and Support

At [Your Company Name], we are committed to providing our customers with exceptional products and unparalleled support. Our free-standing jib cranes are built to the highest standards of quality and durability, and we stand behind them with a comprehensive warranty and support package designed to ensure your complete satisfaction.

Warranty:

We offer a robust [number of years] warranty on all our free-standing jib cranes, covering both materials and workmanship. This warranty begins from the date of purchase, guaranteeing that your jib crane will be free from defects under normal use and service conditions. In the unlikely event that you experience any issues, we will repair or replace any defective parts at no charge to you. Our warranty does not cover damage resulting from improper installation, misuse, or unauthorized modifications.

Support:

Our dedicated support team is always ready to assist you with any questions or concerns you may have regarding your jib crane. We provide:

1. Technical Assistance:

– Expert advice and troubleshooting from our experienced technicians.

– Detailed user manuals and installation guides.

– On-site support for complex issues, ensuring minimal downtime.

2. Customer Service:

– Responsive customer service representatives available [hours of operation].

– Easy access to replacement parts and accessories.

– Clear communication and timely updates on the status of any warranty claims or service requests.

3. Maintenance and Training:

– Comprehensive maintenance programs to extend the life of your jib crane.

– Training sessions and resources to ensure your team can operate the equipment safely and efficiently.

We value your business and strive to create lasting relationships by delivering reliable products backed by exceptional service. For any further inquiries or assistance, please do not hesitate to contact us at [contact information].

List “free standing jib crane” FAQ

Free Standing Jib Crane FAQ

#### What is a Free Standing Jib Crane?

A free standing jib crane is a type of crane anchored to the floor with a vertical mast and a horizontal boom that rotates to lift, move, and position heavy loads.

#### Where are Free Standing Jib Cranes used?

They are commonly used in manufacturing plants, assembly lines, and workshops for tasks requiring repetitive lifting, such as loading machines, moving parts, and positioning materials.

#### What are the key benefits of a Free Standing Jib Crane?

– Versatility: Can be used in various applications and industries.

– Ease of Installation: Simple to install and relocate.

– Cost-Effective: Lower cost of ownership due to reduced labor and maintenance expenses.

– Increased Efficiency: Enhances productivity by lifting and moving heavy objects with minimal effort.

#### How much weight can a Free Standing Jib Crane lift?

Capacities range from 100 pounds to several tons, depending on the model and design specifications.

#### What is the typical span and height for these cranes?

Spans can reach up to 20 feet or more, and heights can range from ground level to several feet above the floor, depending on application needs.

#### Is it possible to customize a Free Standing Jib Crane?

Yes, customization options include varying heights, spans, rotation angles, and lifting capacities to meet specific requirements.

#### How does a Free Standing Jib Crane rotate?

Most models offer 180 to 360-degree rotation, utilizing manual or motorized mechanisms for movement.

#### What maintenance is required?

Regular inspections, lubrication of moving parts, and checking for wear and tear are essential for ensuring longevity and safe operation.

#### Are there any safety considerations?

Yes, adhere to load limits, ensure stable and proper installation, conduct routine inspections, and train operators thoroughly.

#### Can Free Standing Jib Cranes be used outdoors?

They can be used outdoors but should be made of materials or coatings resistant to weather elements like rain, wind, and corrosion.

By addressing these frequently asked questions, users can better understand the application, benefits, and maintenance of free standing jib cranes, ensuring safe and efficient use.

Top 10 FAQ with answer about free standing jib crane for Buyer Sourcing from China

Certainly! Here’s a concise FAQ for buyers sourcing free standing jib cranes from China:

1. What is a Free Standing Jib Crane?

A free standing jib crane is a versatile lifting device with a horizontal arm (jib) that supports hoists and trolleys. It’s ideal for loading docks, workshops, and warehouses.

2. What are the Key Specifications to Consider?

Important specifications include load capacity, jib length, rotation angle, lifting height, and type of hoist. Ensure they match your operational needs.

3. What is the Load Capacity Range Available?

Chinese manufacturers typically offer jib cranes with load capacities ranging from 0.5 to 15 tons. Custom capacities are often available upon request.

4. How Long Does Delivery Take?

Lead times can vary. On average, manufacturing takes 4-6 weeks and shipping 2-6 weeks, depending on your location and shipping method.

5. Are Custom Designs Possible?

Yes, many suppliers offer customization options for jib arm length, load capacity, and hoist type to meet specific requirements.

6. What Standards and Certifications Should I Look For?

Look for compliance with international standards like ISO, CE, and ANSI. Certification ensures the crane meets quality and safety regulations.

7. What Are Typical Payment Terms?

Common payment terms include a 30% deposit upon order confirmation and the remaining 70% before shipment. Some suppliers may offer LC (Letter of Credit) options.

8. How is Shipping Handled?

Manufacturers generally handle shipping logistics and provide options for sea, air, or land transport. Cranes are shipped in disassembled form to streamline transportation.

9. What About After-Sales Support and Warranty?

Most suppliers offer a 12- to 24-month warranty, covering parts and labor. After-sales support typically includes technical support, spare parts, and maintenance guidance.

10. How do I Ensure the Supplier is Reliable?

Research supplier background, check certifications, read customer reviews, and, if possible, visit their manufacturing facility or request a third-party inspection.

This streamlined FAQ aims to address vital questions buyers might have when sourcing free standing jib cranes from China.