40 ton crane Safety Certifications

Operating a 40-ton crane involves ensuring the equipment and operators meet stringent safety standards. Key certifications and practices include:

1. OSHA Compliance: The U.S. Occupational Safety and Health Administration (OSHA) sets regulations for crane operations, including proper maintenance, inspection, and operator qualifications. Compliance with OSHA standards is mandatory.

2. ASME B30.5: The American Society of Mechanical Engineers (ASME) provides guidelines specifically for mobile and locomotive cranes. The B30.5 standard covers safety practices, maintenance, and inspection criteria.

3. NCCCO Certification: Operators should be certified by the National Commission for the Certification of Crane Operators (NCCCO). This certification ensures that operators are knowledgeable and skilled in safe crane operation.

4. Annual Inspections: Regular inspections by qualified personnel are mandated. ANSI/ASME standards require annual inspections, focusing on the crane’s structural integrity, mechanical components, and safety features.

5. Manufacturer’s Guidelines: Adhering to the crane manufacturer’s safety recommendations is crucial. These guidelines provide specific maintenance intervals, load capacities, and operational protocols.

6. HAZWOPER Certification: If operating in hazardous conditions, operators may need Hazardous Waste Operations and Emergency Response (HAZWOPER) certification to handle potential risks.

7. Fall Protection Training: Crane operators and riggers often work at heights, necessitating fall protection training and proper use of personal protective equipment (PPE).

8. CPR and First Aid Training: Basic First Aid and CPR training for operators and on-site personnel can be crucial in responding to emergency situations.

Implementing these certifications and maintaining rigorous adherence to safety protocols reduces the risk of accidents, ensuring a safe working environment around a 40-ton crane.

List Reference Technical Parameters of “40 ton crane”

The 40-ton crane is a versatile piece of machinery used in various construction and industrial applications. Here are some of the reference technical parameters for a typical 40-ton crane:

1. Lifting Capacity: 40 tons (36,287 kilograms).

2. Boom Length: Ranges from 9.2 meters (30 feet) to 30.1 meters (98.75 feet). Some models offer extendable or telescoping booms.

3. Jib Length: Optional jibs can increase the reach, typically ranging up to 15 meters (49 feet).

4. Lifting Height: Maximum lifting height can extend to around 40 meters (131 feet) with additional jib configuration.

5. Outrigger Span:

– Front Span: Around 6.2 meters (20.34 feet).

– Rear Span: Around 7.0 meters (22.97 feet).

6. Hoist Speed: Variable, typically between 0 to 120 meters per minute (0 to 394 feet per minute), depending on load and rope layers.

7. Swing Speed: Approximately 2.0 RPM (Revolutions Per Minute).

8. Travel Speed: Can range from 0 to 80 kilometers per hour (0 to 50 miles per hour), influenced by the type and make.

9. Engine Power: Typically ranges from 200 to 300 horsepower (HP), diesel-powered.

10. Tire Size: Commonly equipped with 29.5 x 25 tires or equivalent for adequate ground clearance and traction.

11. Hydraulic System Pressure: Usually operates between 250 to 350 bar (3,625 to 5,075 PSI).

12. Control Systems: Often feature computerized load management and safety systems including Load Moment Indicator (LMI), anti-two block system, and overload protection.

13. Dimensions:

– Length: Approximately 13 meters (42.65 feet).

– Width: Around 2.75 meters (9 feet).

– Height: Close to 3.8 meters (12.46 feet).

14. Weight: Gross vehicle weight can be up to 36,000 kilograms (79,366 pounds).

15. Axles: Typically equipped with 3 to 4 axles for stability and road compliance.

Understanding these parameters is essential for the proper selection, operation, and maintenance of the crane to ensure safe and efficient lifting operations.

List Product features of “40 ton crane”

Certainly! Here are the key product features of a 40-ton crane:

1. Lifting Capacity:

– Can handle loads up to 40 tons (80,000 lbs), suitable for heavy-duty lifting tasks.

2. Boom Length and Configuration:

– Variable boom lengths (often extendable up to or beyond 100 feet) enable flexibility in reaching different heights and distances.

– Telescoping or lattice boom options to suit different operations.

3. Mobility:

– Available in various models, such as truck-mounted, crawler, and all-terrain cranes, providing adaptability to different job site conditions.

4. Operational Range:

– Offers a wide operational range with 360-degree rotation for versatile and efficient positioning of loads.

5. Ease of Transportation:

– Compact design (for truck-mounted models) enhances ease of transportation between job sites, adhering to road travel regulations.

6. Stability Systems:

– Equipped with advanced outriggers and counterweight systems to ensure stability during lifting operations.

7. Control Systems:

– Modern cranes feature advanced electronic control systems, including load moment indicators, anti-two block devices, and computer-aided controls for precision and safety.

8. Safety Features:

– Includes emergency stop functions, load monitoring systems, and operational alerts that ensure safety compliance.

– Overload protection systems to prevent lifting beyond the crane’s rated capacity.

9. Versatility:

– Compatible with a variety of attachments (e.g., hooks, buckets, and grabs) to accommodate different lifting needs.

10. Power Source:

– Typically powered by robust diesel engines, although electric and hybrid models are also available for eco-friendlier operations.

11. Durability:

– Built with high-grade materials to withstand rigorous use in demanding environments, ensuring longevity and reliability.

12. Comfort and Ergonomics:

– Operator cabins are designed for comfort and visibility, often featuring climate control, adjustable seating, and user-friendly interfaces.

13. Maintenance and Support:

– Designed for ease of maintenance with accessible components, supported by manufacturer service networks for quick repairs and parts replacement.

These features make a 40-ton crane an efficient and versatile tool for industries like construction, shipbuilding, and manufacturing, where heavy lifting is a routine requirement.

List Various Types of “40 ton crane”

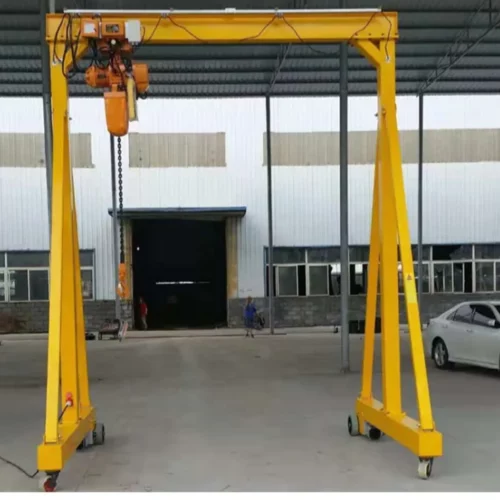

Certainly! A “40 ton crane” refers to cranes with a lifting capacity of 40 tons. Here are various types:

1. Mobile Crane: These cranes are mounted on rubber-tired trucks and offer great mobility. They can travel on highways, making them suitable for various jobs.

2. Rough Terrain Crane: Equipped with large tires and all-wheel drive, these cranes are ideal for off-road and rugged sites.

3. Crawler Crane: Mounted on tracks instead of wheels, crawler cranes offer stability and can easily move around a construction site without setting up outriggers.

4. Truck-Mounted Crane: A hybrid between a truck and a crane, these are ideal for quick setups and can travel on public roads to reach various job sites.

5. All-Terrain Crane: Combining the mobility of a truck-mounted crane with the off-road capabilities of a rough terrain crane, this type is very versatile.

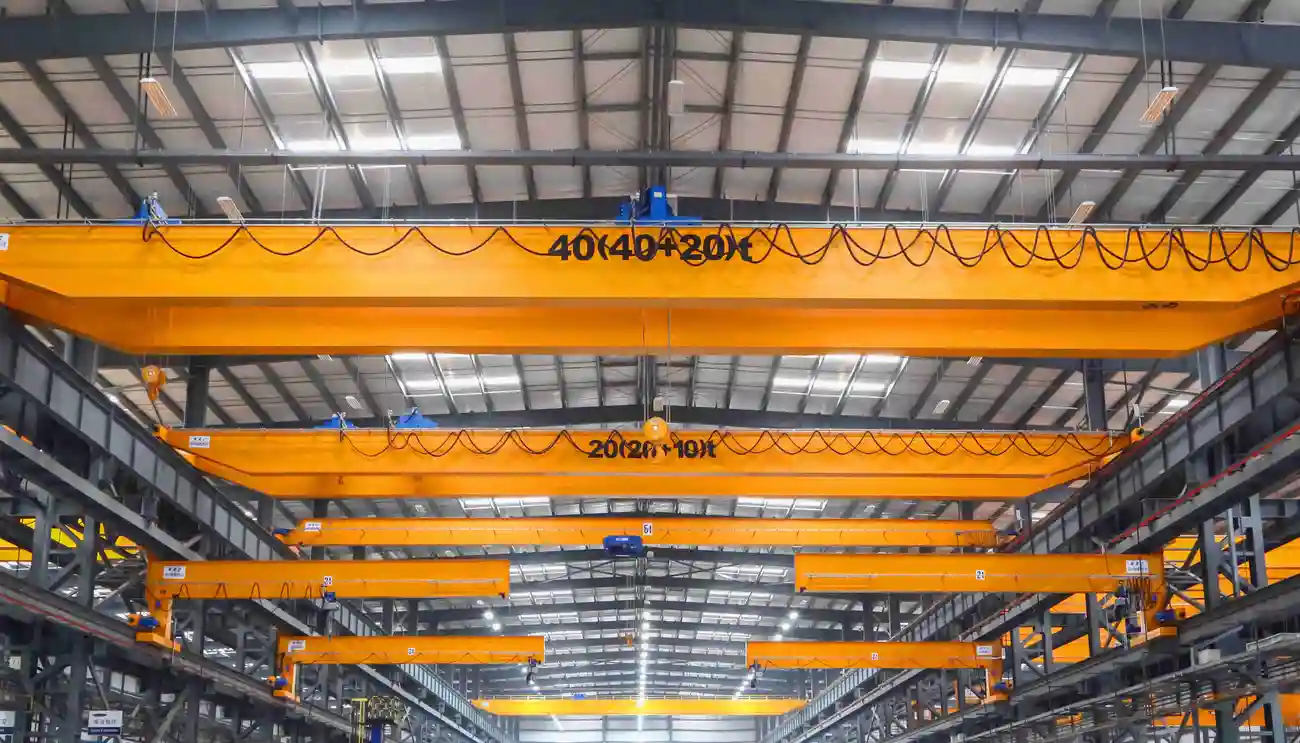

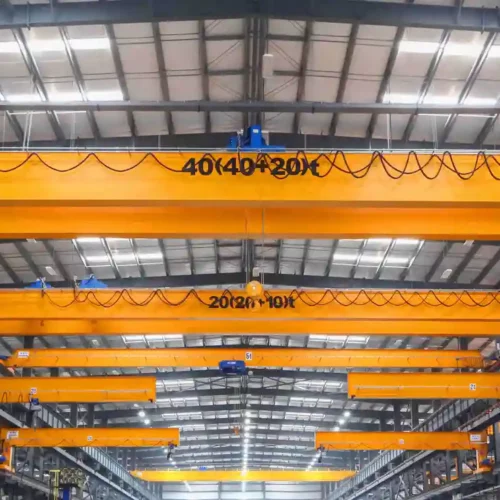

6. Overhead Crane: Typically used in industrial environments, these cranes move along a horizontal beam or gantry system to lift and move heavy loads within a workshop or warehouse.

7. Tower Crane: Commonly seen in urban construction, these cranes have a tall mast and can reach significant heights to support large projects.

8. Boom Truck: These are smaller cranes mounted on a flatbed truck. They offer versatile usage but limited lifting capabilities compared to other mobile cranes.

Each type has its own advantages and is suited to specific job requirements or site conditions. By understanding these various types, you can select the most appropriate 40 ton crane for your needs.

List Application of “40 ton crane”

A 40-ton crane is a versatile piece of equipment used in various industries for lifting and moving heavy loads. Its applications span across multiple sectors:

1. Construction:

– High-Rise Buildings: Lifting steel beams, concrete panels, and other heavy construction materials to considerable heights.

– Bridges: Assembling and placing large sections and components.

2. Manufacturing:

– Assembly Lines: Moving large machinery and components within factories.

– Heavy Equipment Production: Transporting substantial and heavy parts during the assembly process.

3. Infrastructure Development:

– Road and Rail Projects: Lifting and placing concrete segments, rails, and other materials.

– Utilities: Installing and maintaining large utility poles, transformers, and other substantial infrastructural elements.

4. Oil and Gas:

– Onshore and Offshore Rigs: Deploying or retrieving drilling equipment, pipelines, and other heavy materials.

– Refineries: Relocating heavy machinery and refinery components.

5. Shipping and Warehousing:

– Port Operations: Loading and unloading shipping containers and large cargo.

– Warehouse Logistics: Moving bulky inventory and equipment.

6. Mining:

– Extraction Sites: Handling large machinery and excavation equipment.

– Processing Plants: Installing and maintaining processing machinery.

7. Energy:

– Wind Farms: Erecting wind turbine components such as nacelles, blades, and towers.

– Power Plants: Lifting heavy electrical components and assemblies.

8. Maintenance and Repairs:

– Industrial Plants: Assisting in the maintenance and relocation of heavy machinery.

– Municipal Services: Replacing or installing large-scale public infrastructure elements.

The 40-ton crane’s capacity makes it an essential tool for projects requiring the handling of heavy and substantial materials efficiently and safely. Its ability to perform in diverse environments underscores its indispensability in modern industrial operations.

List Buyer Types of “40 ton crane”

When considering the purchase of a 40-ton crane, several types of buyers may be involved, each with distinct needs and motivations. Here’s a brief overview:

1. Construction Companies:

– Use Case: These buyers need cranes for various construction tasks such as lifting heavy steel beams, concrete panels, and other materials.

– Key Factors: Mobility, versatility, and safety are critical considerations.

2. Industrial Manufacturing Plants:

– Use Case: Plants may utilize cranes to move large, heavy components during the manufacturing process.

– Key Factors: Precision, repeatability, and integration with existing workflow and automation systems.

3. Shipping and Logistics Firms:

– Use Case: These buyers require cranes to load and unload cargo in ports and warehouses.

– Key Factors: Efficiency, speed of operation, and reliability for continuous use.

4. Mining Operations:

– Use Case: Cranes are used to handle heavy mining equipment and materials.

– Key Factors: Durability, ruggedness, and the ability to operate in challenging environmental conditions.

5. Energy Sector (Oil and Gas, Wind Farms):

– Use Case: Cranes are needed for constructing and maintaining energy infrastructures such as wind turbines, oil rigs, and pipelines.

– Key Factors: High lifting capacity, stability, and adaptability to different terrains.

6. Rental Companies:

– Use Case: Rental companies may buy these cranes to lease them out to other sectors needing temporary heavy lifting solutions.

– Key Factors: Versatility, ease of transport, and low maintenance costs.

7. Municipalities and Public Works:

– Use Case: Used for large public projects such as bridge construction, infrastructure development, and disaster recovery efforts.

– Key Factors: Public safety, reliability, and cost-effectiveness.

Each buyer type has unique requirements, but all seek efficiency, safety, and reliability in a 40-ton crane. Understanding the specific needs and operational contexts of these buyers helps manufacturers tailor their products accordingly.

List “40 ton crane” Project Types for Different Industries

Certainly! A 40-ton crane is versatile and finds application across a variety of industries, given its capacity and maneuverability. Here are some common project types in different sectors:

Construction

1. Building Erection: Used for lifting heavy steel beams, panels, and other structural components.

2. Bridge Construction: Helps in placing bridge segments and supporting temporary structures.

3. Skyscraper Development: Facilitates the installation of elevators, HVAC units, and other high-altitude tasks.

Manufacturing

1. Assembly Line Setup: Aids in positioning heavy machinery pieces.

2. Component Transportation: Moves heavy components across the plant.

3. Plant Maintenance: Assists in maintaining large equipment and replacing parts.

Oil and Gas

1. Rig Installation: Deployed for set-up and disassembling of drilling rigs.

2. Pipeline Construction: Assists in laying down pipeline segments.

3. Refinery Maintenance: Helps in maintenance and upgrading of refinery towers and vessels.

Renewable Energy

1. Wind Turbine Installation: For mounting turbine blades and nacelles.

2. Solar Farm Setup: Places heavy solar panels and support structures.

3. Hydro Plant Construction: Facilitates the installation of equipment in hydroelectric plants.

Transportation and Logistics

1. Port Operations: Loads and unloads shipping containers.

2. Railway Construction: Lifts railway tracks and other heavy components.

3. Airport Infrastructure: Assists in the installation of airfield lighting and signage.

Mining

1. Equipment Installation: Sets up machinery like crushers and conveyors.

2. Site Development: Helps in constructing infrastructures such as processing plants.

3. Material Handling: Moves large quantities of extracted materials.

Utility Services

1. Power Line Installation: Used for erecting utility poles and laying cables.

2. Waste Management: Assists in handling large waste containers.

3. Water Treatment Plants: Facilitates the assembly of large tanks and filtration units.

Event Management

1. Concerts and Festivals: Sets up large stages, lighting rigs, and audio-visual equipment.

2. Exhibitions: Helps in erecting large exhibition structures and displays.

3. Sporting Events: Assists in construction of temporary stands, scoreboard installations, and other structures.

This broad range of applications demonstrates the flexibility and importance of a 40-ton crane across different sectors.

40 ton crane Accessories Upgrades and Custom Manufacturing Options

When upgrading a 40-ton crane or considering custom manufacturing options, it’s crucial to optimize for efficiency, safety, and versatility. Key accessories and upgrades include:

1. Load Monitoring Systems: Advanced load cells and digital displays for precise weight measurement and overload protection.

2. Remote Control Operation: Wireless control systems provide safe, remote operation, reducing the need for personnel in hazardous zones.

3. Anti-Sway Technology: Enhances load stability during transit by minimizing oscillation.

4. Variable Frequency Drives (VFD): Improves speed control and energy efficiency, offering smoother acceleration and deceleration.

5. Custom Lifting Attachments: Specialized hooks, grapples, and spreader beams tailored to specific materials or operational requirements.

6. Weather Protection: Enclosures and coating upgrades protect against harsh environmental conditions, extending crane longevity.

7. Camera Systems: High-resolution cameras enhance visibility for operators, increasing precision and safety.

8. Automated Positioning: GPS and laser systems for precise load placement and crane positioning.

9. Seismic Upgrades: Structural reinforcements and shock absorbers to improve performance during seismic events.

10. Operator Cab Upgrades: Ergonomic seats, climate control, and improved visibility features enhance operator comfort and efficiency.

Custom manufacturing options often cater to unique operational needs. Tailored boom lengths, enhanced lifting capacities, and specialized chassis designs ensure the crane meets specific industry requirements. Additionally, custom software interfaces for integrating crane operations with existing facility management systems can offer streamlined workflow and productivity.

Overall, selecting the right combination of accessories and custom manufacturing options can significantly boost the operational efficiency, safety, and lifespan of a 40-ton crane.

List Quality Control and The Manufacturing Process of “40 ton crane”

Quality Control for 40-Ton Crane

1. Materials Inspection: Verify steel and other critical components for composition and strength.

2. Dimensional Accuracy: Ensure all parts meet design specifications using precision measurement tools.

3. Welding Inspection: Conduct visual and ultrasonic tests to check for defects in welds.

4. Load Testing: Perform stress tests to certify the crane can handle 40 tons safely.

5. Non-Destructive Testing (NDT): Use radiography, magnetic particle, and dye penetrant tests to identify internal flaws.

6. Functional Testing: Test all mechanical and electrical systems for proper operation.

7. Compliance Checks: Ensure adherence to industry standards and regulations (e.g., ISO, ASME).

8. Final Inspection: A thorough check before dispatch, including documentation reviews.

Manufacturing Process of a 40-Ton Crane

1. Design and Engineering:

– CAD/CAE software to create precise design.

– Structural analysis to ensure safety and performance.

2. Materials Procurement:

– Sourcing high-grade steel and essential components.

– Quality assurance checks on incoming materials.

3. Cutting and Shaping:

– Plasma or laser cutting for precision shapes.

– CNC machining for parts requiring high accuracy.

4. Welding and Fabrication:

– Assembling crane components using welding techniques.

– Ensuring weld quality through constant inspection.

5. Machining:

– Machining operations on bolted joints and moving parts.

– Quality control checks post-machining.

6. Assembly:

– Assembling structural components.

– Installation of electrical systems, motors, and winches.

7. Surface Treatment:

– Sandblasting for rust and impurity removal.

– Applying primer and paint for corrosion resistance.

8. Rigging and Testing:

– Preliminary assembly of boom, jib, and counterweights.

– Conducting load tests to verify lifting capacity.

9. Final Assembly:

– Integrating all components on-site.

– Conducting comprehensive system checks.

10. Quality Assurance and Certification:

– Final inspection and testing.

– Issuing compliance certifications and documentation.

Adhering to these rigorous processes ensures the reliability and safety of a 40-ton crane.

How to use “40 ton crane”

Using a 40-ton crane involves several key steps to ensure safe and efficient operation. Here’s a concise guide:

1. Pre-Operation Checklist:

– Inspect the Crane: Verify that the crane is in good working condition. Check fluid levels, cables, hooks, and safety devices.

– Examine the Load: Ensure the load does not exceed the crane’s 40-ton capacity. Calculate the weight accurately.

– Site Assessment: Survey the worksite for obstacles, ground stability, and overhead hazards. Define a safe operating zone.

2. Setup:

– Position the Crane: Station the crane on a stable and level surface. Use outrigger pads to distribute the load.

– Balance and Level: Extend outriggers fully and check the crane’s level using a spirit level.

3. Lifting Procedure:

– Attach the Load: Securely attach the load to the crane hook with appropriate rigging gear. Double-check all connections.

– Communication: Establish clear communication with the ground crew using hand signals or radios. Designate a signal person if necessary.

– Lift Slowly: Start lifting slowly, lifting the load a few inches to test stability. Confirm balance and adjust if needed.

4. Operating the Crane:

– Control Movements: Operate the crane using the control panel or remote, following the lifts path precisely. Avoid sudden jerks.

– Monitor Continuously: Keep an eye on the load, crane, and surroundings throughout the operation.

5. Setting Down the Load:

– Lower Gently: Lower the load slowly to the designated spot, maintaining control.

– Dismantle Rigging: Once the load is securely placed, carefully detach the rigging.

6. Post-Operation:

– Inspect: Conduct a post-operation inspection to ensure the crane and rigging are in good condition for future use.

– Report: Document any issues or incidents during the operation.

Always follow the manufacturer’s specific guidelines and local safety regulations. Operator certification is crucial for safe crane operation.

“40 ton crane” Comparative Analysis

A 40-ton crane is a valuable asset in construction, manufacturing, and other industries requiring the lifting of heavy loads. Various types of 40-ton cranes are available, each with unique features, advantages, and limitations. The primary categories include mobile cranes, tower cranes, and overhead cranes.

Mobile Cranes: These cranes, such as truck-mounted cranes and all-terrain cranes, offer flexibility and mobility. They can navigate on roads and access various job sites without extensive setup. They are ideal for short-term projects and situations where frequent relocation is necessary. However, their lifting capacity can be affected by the ground conditions and weight distribution.

Tower Cranes: These fixed cranes are prominent in high-rise construction projects. They provide a higher lifting height and a stable foundation, making them suitable for reaching great heights and distances. Tower cranes require a concrete base and are more labor-intensive to assemble and dismantle. They are not as mobile as other crane types but excel in large-scale, long-term projects.

Overhead Cranes: Often used in industrial settings, these cranes run on rails mounted on the ceiling. They maximize floor space and are capable of precise, repeated movements. Overhead cranes are well-suited for indoor environments like warehouses and manufacturing plants. Their major drawback is limited mobility since they are confined to the rail system.

Comparative Analysis:

– Mobility: Mobile cranes are the most versatile, suitable for multiple locations. Overhead and tower cranes are site-specific.

– Setup Time: Mobile cranes have the quickest setup, while tower cranes have the longest.

– Lifting Height: Tower cranes excel in height capabilities, followed by mobile cranes. Overhead cranes usually lift within the confines of a structure.

– Operational Environment: Overhead cranes are ideal for indoor use, tower cranes for high-rise buildings, and mobile cranes for diverse locations.

– Cost: Mobile cranes generally entail lower initial setup costs and are effective for short-term needs, whereas tower cranes, despite higher setup costs, are cost-efficient for long-term projects.

Each type of 40-ton crane has its specific applications, and the choice depends on the operational environment, project duration, mobility requirements, and lifting height needs.

“40 ton crane” Warranty and Support

When you invest in a 40-ton crane, securing a reliable warranty and robust support services is crucial to maximize uptime and minimize unexpected costs. Here is a comprehensive overview of what to look for in warranty and support.

Warranty

1. Duration: Typically, warranties for a 40-ton crane range from 1 to 5 years. A longer warranty period often reflects the manufacturer’s confidence in the crane’s durability.

2. Coverage: Ensure the warranty covers essential components such as the hoist, motor, gearbox, and electrical systems. Some warranties also include coverage for structural integrity.

3. Exclusions: Be aware of exclusions like normal wear and tear, misuse, and unauthorized modifications. Understanding these exclusions can help you maintain the warranty’s validity.

Support

1. 24/7 Technical Support: Immediate access to technical support can be indispensable. Ensure the manufacturer or dealer offers 24/7 support to quickly address any operational issues.

2. Maintenance Plans: Consider enrolling in a maintenance plan to ensure regular inspections and tune-ups. This can extend the crane’s life and ensure compliance with safety regulations.

3. Spare Parts Availability: Verify that spare parts are readily available and can be delivered quickly to minimize downtime.

4. Training Programs: Proper training for operators and maintenance staff can significantly reduce the likelihood of operational errors and enhance safety. Look for manufacturers or dealers that offer comprehensive training programs.

5. Local Service Centers: Opt for brands that have a network of service centers or certified technicians nearby. Prompt on-site service can be crucial for minimizing downtime.

6. Extended Support Options: Some providers offer extended support packages that include things like annual inspections, remote monitoring, and performance analytics.

Selecting a 40-ton crane with a solid warranty and extensive support options ensures that your heavy lifting needs are met reliably and efficiently over the long term.

List “40 ton crane” FAQ

40 Ton Crane FAQ

1. What is a 40 ton crane?

A 40 ton crane is a lifting machine designed to hoist, lower, and move loads up to 40 tons (80,000 pounds). It is commonly used in construction, manufacturing, and other industries requiring heavy lifting.

2. What types of 40 ton cranes are available?

Common types include mobile cranes, overhead cranes, and tower cranes. Mobile cranes offer flexibility and are mounted on trucks or crawlers. Overhead cranes are fixed and used in factories. Tower cranes are used in construction for high-rise buildings.

3. What are the dimensions and weight of a 40 ton mobile crane?

Dimensions and weight vary by model and manufacturer. Generally, expect a length of 30-40 feet, a width of 8-10 feet, and a height of 10-12 feet. The weight can range from 20 to 40 tons, excluding the load.

4. How far can a 40 ton crane reach?

Reach, or boom length, can vary but typically ranges from 100 to 200 feet. This is influenced by the model and any additional attachments like lattice or telescopic booms.

5. What factors influence the lifting capacity?

Lifting capacity is influenced by boom length, angle, radius from the crane’s center, and additional counterweights. Always refer to the crane’s load chart for precise calculations.

6. What safety precautions should be taken?

Ensure the crane is operated by a certified operator. Perform regular inspections, use proper rigging, avoid overloading, and consider environmental factors like wind conditions.

7. What maintenance is required for a 40 ton crane?

Regular maintenance includes inspecting and lubricating mechanical parts, checking hydraulic systems, and ensuring electrical components are functional. Follow the manufacturer’s maintenance schedule closely.

8. What is the cost to rent or buy a 40 ton crane?

Renting a 40 ton crane can range from $200 to $1,000 per day, depending on the duration and location. Purchasing one can cost $150,000 to over $500,000, influenced by brand, condition, and features.

9. How do I choose the right 40 ton crane?

Consider the lifting capacity, reach requirements, mobility, and specific application needs. Consulting with a specialist can help you select the most suitable model.

10. Are permits required?

Yes, operating a 40 ton crane typically requires permits, which vary based on location and the specific job. Always check local regulations.

Top 10 FAQ with answer about 40 ton crane for Buyer Sourcing from China

1. What are the types of 40-ton cranes available?

– Answer: The main types include mobile cranes, tower cranes, overhead cranes, and gantry cranes. Each type serves different construction and industrial needs.

2. What is the average cost of a 40-ton crane from China?

– Answer: The cost can vary significantly based on specifications, brand, and features. Generally, it ranges between $80,000 to $150,000, excluding shipping and customs duties.

3. What certifications should the 40-ton crane have?

– Answer: Look for ISO 9001 quality management certification, CE marking for European standards, and CCC (China Compulsory Certification) to ensure compliance with safety and quality regulations.

4. How long is the delivery time for a 40-ton crane?

– Answer: Typically, the delivery time ranges from 30 to 60 days, depending on the manufacturer and customization requirements.

5. What are the warranty terms for a 40-ton crane?

– Answer: Most manufacturers offer a 1 to 2-year warranty covering parts and labor. Be sure to confirm the specifics with the supplier and read the warranty terms carefully.

6. Are spare parts readily available?

– Answer: Reputable suppliers generally offer a full range of spare parts. It’s advisable to confirm the availability and potential shipping time for spare parts before purchasing.

7. What should be checked before purchasing a 40-ton crane?

– Answer: Verify the crane’s load capacity, lifting height, operating speed, and power requirements. Additionally, check for after-sales service and the availability of technical support.

8. Can the crane be customized?

– Answer: Yes, many manufacturers offer customization options to meet specific project requirements, including special lifting attachments and automation features.

9. What is the best way to find a reliable Chinese crane manufacturer?

– Answer: Use platforms like Alibaba, Made-in-China, and Global Sources. Check customer reviews, company certifications, and request quotes from multiple suppliers for comparison.

10. How do I handle shipping and import duties?

– Answer: Work with a freight forwarder experienced in importing heavy machinery. Ensure you are aware of your country’s import regulations and duties to avoid unexpected costs.