1 ton gantry crane Safety Certifications

A 1-ton gantry crane must adhere to several safety certifications and standards to ensure safe operation. These include:

1. OSHA (Occupational Safety and Health Administration): OSHA sets rigorous guidelines for workplace safety. Cranes must comply with OSHA 29 CFR 1910.179, which covers overhead and gantry cranes. This includes regular inspections, proper maintenance, and operator training.

2. ASME (American Society of Mechanical Engineers): ASME B30.2 standards specifically address overhead and gantry cranes, focusing on design, construction, inspection, and operation. Compliance ensures that the crane meets the highest engineering and safety standards.

3. ANSI (American National Standards Institute): ANSI/ASME B30.17 covers the safety requirements for top-running and under-running bridge and gantry cranes, including hoists and trolleys. Adherence to these standards ensures the mechanical and structural integrity of the crane.

4. CMAA (Crane Manufacturers Association of America): CMAA Specification No. 70 includes guidelines for the construction of electric overhead traveling cranes, such as gantry cranes. This specification sets forth the criteria for design and operating practices.

5. Inspection and Maintenance: Regular inspection and maintenance are crucial. Per OSHA guidelines, frequent (daily or pre-shift) and periodic (monthly to annually) inspections are mandatory. Components such as hooks, ropes, limit switches, and safety latches must be regularly checked for wear and defect.

6. Operator Certification and Training: Operators must be adequately trained and certified to handle the crane safely. Training programs should align with OSHA and ASME guidelines, teaching safe handling, inspection procedures, and emergency protocols.

7. Load Testing: Before initial use, the crane should undergo load testing to verify that it can safely lift loads up to its rated capacity. Load tests typically involve lifting a weight up to 125% of the crane’s rated capacity.

Ensuring compliance with these safety certifications minimizes risks and enhances the operational safety of a 1-ton gantry crane.

List Reference Technical Parameters of “1 ton gantry crane”

A 1-ton gantry crane is a versatile lifting solution used in various industrial and construction settings. Below are the key technical parameters to consider:

1. Capacity: 1 metric ton (1,000 kg or 2,204.62 lbs).

2. Span: The horizontal distance between the two legs of the crane can vary, typically ranging from 2 to 10 meters depending on the model and application requirements.

3. Lifting Height: The maximum height the crane can lift a load. This can vary but generally ranges from 2 to 6 meters.

4. Hoist Type: Can be manual, electric, or pneumatic. Commonly, electric hoists are used for ease and efficiency.

5. Hoist Speed: The rate at which the hoist can raise or lower the load. Speeds typically range from 0.8 to 8 meters per minute.

6. Trolley Type: Manual push/pull or motorized. This affects how the hoist moves along the gantry beam.

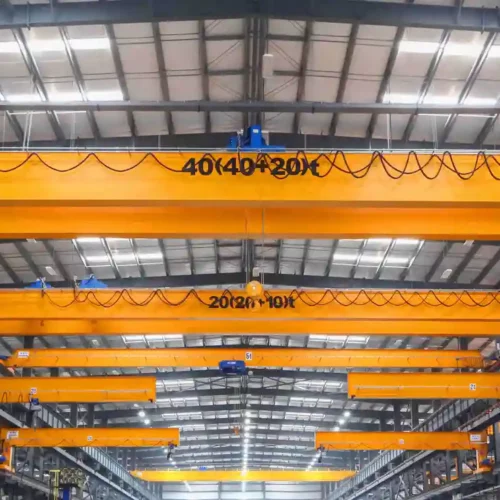

7. Beam Type: Typically I-beam or H-beam design, chosen based on load requirements and structural considerations.

8. Wheel Type: Polyurethane or steel wheels. Polyurethane is quieter and better for indoor use, while steel wheels are more durable for outdoor and heavy-duty use.

9. Adjustability: Some models offer adjustable height and span, allowing for greater flexibility in various work environments.

10. Power Supply: For electric models, common options are 220V, 380V, or 440V, 50/60Hz, single or three-phase.

11. Control Methods: Pendant control, wireless remote control, or push button station for operating the hoist and trolley.

12. Safety Features: Overload protection, emergency stop button, limit switches for lifting height, and anti-drop devices for enhanced security.

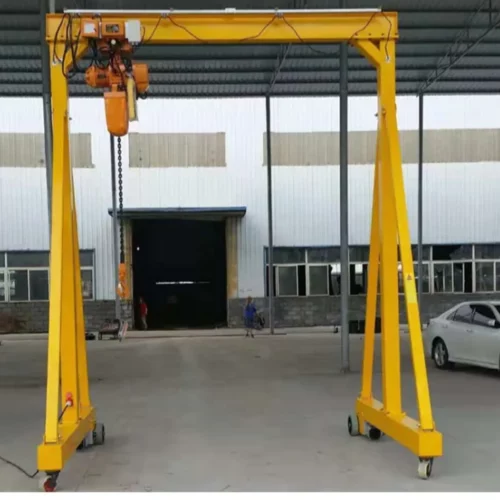

13. Portability: Some gantry cranes are equipped with caster wheels, making them portable and easy to move within a workspace.

14. Construction Material: High-quality steel for durability and strength, often treated for corrosion resistance if used in outdoor or harsh environments.

15. Compliance: Conforms to relevant standards and regulations, such as OSHA, ANSI, or CE certifications.

These parameters can influence the performance, suitability, and safety of the gantry crane for specific applications.

List Product features of “1 ton gantry crane”

A 1-ton gantry crane is a versatile and essential piece of equipment for lifting and moving heavy loads in various industrial settings. Here are the key product features:

1. Load Capacity: Capable of lifting loads up to 1 ton (2000 lbs), making it suitable for a variety of applications.

2. Adjustable Height: Many models offer adjustable height options to accommodate different working conditions and clearance requirements.

3. Span Width: Typically features a span width that ranges from 8 to 20 feet, allowing flexibility in the working area.

4. Mobile Design: Equipped with durable polyurethane casters or wheels for easy movement and positioning within the workspace.

5. Material Construction: Constructed from high-strength steel or aluminum, ensuring durability and long-term use.

6. Ease of Assembly: Designed for easy and quick assembly, often using bolt-together components to minimize downtime.

7. Safety Features: Includes safety locking mechanisms, overload protection, and secure lifting hooks to ensure safe operation.

8. Manual or Motorized Options: Available in both manual and motorized versions, catering to different operational needs.

9. Versatility: Suitable for various industries such as manufacturing, warehousing, shipping, and maintenance operations.

10. Cost-Effective: Offers a cost-efficient solution for lifting and transporting heavy loads, reducing the need for more expensive lifting equipment.

11. Portability: Some models are designed to be easily disassembled and transported for use in different locations.

12. Customization: Options for customized configurations to meet specific operational requirements, including different span lengths, caster styles, and lifting heights.

13. Weather Resistance: Models intended for outdoor use are often treated with weather-resistant coatings to withstand various environmental conditions.

14. Compliance: Meets industry safety standards and regulations, ensuring reliable and safe performance.

15. Accessories: Compatibility with various accessories such as electric hoists, trolleys, and beam clamps to enhance functionality.

In summary, a 1-ton gantry crane is a practical and adaptable tool designed to improve efficiency and safety in lifting and moving heavy loads, with numerous features that cater to a wide range of industrial applications.

List Various Types of “1 ton gantry crane”

A 1-ton gantry crane is a versatile lifting solution used in various industries for lifting and moving heavy objects. Here are several types of 1-ton gantry cranes:

1. Portable Gantry Crane:

– Description: Lightweight and easy to assemble, these cranes can be moved around the workspace to lift loads as needed.

– Applications: Ideal for workshops, garages, and smaller scale construction projects.

2. Adjustable Height Gantry Crane:

– Description: Features adjustable height for versatility in handling different load heights and working environments.

– Applications: Useful in varied settings where lifting heights need regular adjustments, such as maintenance facilities.

3. Fixed Height Gantry Crane:

– Description: These cranes have a set height, providing stability and sturdiness while lifting.

– Applications: Suitable for environments where the height of lifting remains constant, such as warehouses and production lines.

4. Aluminum Gantry Crane:

– Description: Made from aluminum, these cranes are corrosion-resistant and lightweight, making them easy to transport and assemble.

– Applications: Perfect for outdoor and indoor use where corrosion resistance is critical.

5. Steel Gantry Crane:

– Description: Constructed from steel, these cranes are robust and durable, capable of handling heavy-duty operations.

– Applications: Ideal for industrial settings requiring long-term durability and strength.

6. Motorized Gantry Crane:

– Description: Incorporates motorized mechanisms for traveling and lifting, reducing manual effort and increasing efficiency.

– Applications: Suitable for large-scale operations needing frequent lifting and transportation of heavy objects.

7. Reinforced Gantry Crane:

– Description: Designed with additional reinforcing features to handle more demanding environments and ensure extra stability.

– Applications: Optimal for heavy industrial environments with vigorous and frequent operations.

8. Cantilever Gantry Crane:

– Description: Features a cantilevered design enabling the crane to reach over obstacles or cover a larger area.

– Applications: Useful in settings where part of the process or load might extend beyond the crane’s base footprint.

Each type of 1-ton gantry crane is designed to meet specific needs, ensuring efficiency and safety across various applications.

List Application of “1 ton gantry crane”

A 1-ton gantry crane is a versatile lifting device used in various industries for handling and moving heavy loads. Here are some key applications:

1. Manufacturing and Assembly Lines:

– Gantry cranes are used to lift and transport parts and components within production facilities, improving efficiency and reducing manual labor.

2. Warehousing and Logistics:

– In warehouses, gantry cranes assist in the loading and unloading of goods, organizing inventory, and moving heavy items that are difficult to handle manually.

3. Construction Sites:

– These cranes are essential for lifting and positioning construction materials such as steel beams, concrete panels, and other heavy components, enhancing safety and productivity on-site.

4. Maintenance and Repair Shops:

– Gantry cranes facilitate the lifting of engines, machinery, and other heavy equipment, making it easier for technicians to perform maintenance and repairs.

5. Automotive Industry:

– In automotive manufacturing and repair shops, gantry cranes help in the assembly of vehicles and the handling of heavy parts like engines and transmissions.

6. Shipyards and Marine Industry:

– Used for lifting and moving heavy marine equipment, boat engines, and other components, gantry cranes are crucial for shipbuilding and repair operations.

7. Small-Scale Workshops:

– Ideal for small-scale operations where space is limited, gantry cranes provide an affordable and flexible lifting solution for various workshop activities.

8. Recycling and Scrap Yards:

– These cranes assist in handling and moving heavy scrap materials and recyclables, streamlining the sorting and processing operations.

9. Power Plants:

– Gantry cranes are used to handle heavy components like turbines and generators, facilitating maintenance and operational tasks in power generation facilities.

10. Educational Institutions and Laboratories:

– Used for research and educational purposes, gantry cranes help in the handling of heavy experimental setups and equipment in technical institutions.

Each of these applications leverages the gantry crane’s ability to provide a reliable, mobile, and efficient solution for lifting and transporting heavy loads.

List Buyer Types of “1 ton gantry crane”

When it comes to purchasing a 1-ton gantry crane, several types of buyers emerge based on their specific needs and operational contexts. Here are the primary buyer types:

1. Small Manufacturing Units:

– Description: Small-scale manufacturing companies that engage in light to medium-duty tasks.

– Requirement: Occasional lifting of materials, parts, or assemblies within their production areas.

– Focus: Cost-effectiveness, ease of installation, and versatility.

2. Warehouses and Storage Facilities:

– Description: Facilities that handle a variety of goods and materials needing efficient movement and storage.

– Requirement: Routine lifting and positioning of inventory items.

– Focus: Mobility, ease of operation, and load handling capacity.

3. Maintenance Workshops:

– Description: Workshops dedicated to vehicle, equipment, or machinery repair.

– Requirement: Frequent lifting and maneuvering of heavy components for repair tasks.

– Focus: Durability, precision, and safety features.

4. Construction Companies:

– Description: Firms engaged in construction activities that require on-site material lifting.

– Requirement: Portable lifting solutions for project sites with varying demands.

– Focus: Portability, robustness, and adaptability.

5. Research and Educational Institutions:

– Description: Universities and labs where various experimental setups necessitate material handling.

– Requirement: Occasional lifting for experimental setups and equipment relocation.

– Focus: Flexibility, ease of use, and minimal maintenance.

6. Art Installers and Event Management Companies:

– Description: Companies involved in setting up art installations, exhibitions, and large-scale events.

– Requirement: Lifting and positioning of heavy decorative elements and equipment.

– Focus: Aesthetic integration, ease of transport, and set-up efficiency.

7. Marine Facilities:

– Description: Marinas and boat repair shops where small vessels and equipment are handled.

– Requirement: Lifting and movement of boats and marine equipment.

– Focus: Corrosion resistance, durability, and load capacity.

Each of these buyer types has unique considerations, but commonly, the focus revolves around the crane’s capacity, mobility, ease of operation, and overall cost-effectiveness.

List “1 ton gantry crane” Project Types for Different Industries

Gantry cranes are versatile lifting devices used across various industries due to their mobility, flexibility, and capacity to handle heavy loads efficiently. Here’s a look at project types in different industries that might utilize a 1-ton gantry crane:

Manufacturing and Assembly:

– Product Assembly Line: For moving parts and assemblies through different stages of the manufacturing process.

– Machine Maintenance: Lifting and placing heavy components for repair and maintenance of machinery.

Warehousing and Logistics:

– Loading and Unloading: Efficiently handling pallets and heavy packages from transport vehicles.

– Inventory Organization: Shifting and organizing heavy loads within storage areas.

Construction:

– Material Handling: Transporting construction materials like steel beams, concrete blocks, and other heavy equipment on-site.

– Component Placement: Assisting in the placement of structural components during building construction.

Automotive:

– Engine Lifting: Removing and installing engines or heavy auto parts in maintenance shops.

– Vehicle Assembly: Assisting with the lifting of vehicle components during the manufacturing process.

Marine and Shipbuilding:

– Boat Maintenance: Lifting and positioning boat components, engines, and heavy equipment during maintenance and assembly.

– Dockyard Operations: Handling cargo and equipment at dockyards.

Aerospace:

– Aircraft Maintenance: Hoisting aircraft parts for maintenance and repair.

– Assembly Line: Moving large components and assemblies during aircraft manufacturing.

Mining:

– Equipment Handling: Moving and maintaining large mining equipment.

– Ore Processing: Assisting with the handling of heavy minerals and ore in processing plants.

Energy:

– Wind Turbine Assembly: Lifting heavy components during the assembly and installation of wind turbines.

– Power Plant Maintenance: Handling heavy equipment and components in power generation facilities.

Military:

– Maintenance Depot: Lifting heavy military equipment and machinery for maintenance.

– Field Operations: Mobile units for transporting and assembling gear in varying terrains.

Food and Beverage:

– Bulk Material Handling: Moving heavy bulk items like large containers of ingredients or finished products.

– Machine Upkeep: Facilitating the maintenance of heavy processing equipment.

These project types demonstrate the versatility of a 1-ton gantry crane, making it an indispensable tool across a wide range of industries. Its ability to facilitate the efficient and safe movement of heavy materials boosts productivity and ensures operational safety.

1 ton gantry crane Accessories Upgrades and Custom Manufacturing Options

A 1-ton gantry crane is a versatile piece of equipment, often utilized in workshops, warehouses, and construction sites for lifting and moving heavy loads. To enhance its functionality, various accessories, upgrades, and custom manufacturing options are available:

1. Wheels and Casters: For improved mobility, heavy-duty wheels or casters can be added, allowing for easy maneuverability across different surfaces, including smooth warehouse floors or rugged outdoor terrains.

2. Electric Hoists: Upgrading to an electric hoist can significantly increase lifting efficiency and reduce manual labor. Options include single-speed, dual-speed, and variable-speed hoists to suit various operational requirements.

3. Adjustable Height: Customizable height adjustments allow the crane to be adapted for different lifting tasks and varying workspace constraints, providing greater flexibility.

4. Remote Control Systems: Adding wireless or wired remote control systems enhances safety and efficiency by allowing operators to control the crane from a distance, minimizing the need to be in close proximity to the load.

5. Load Indicators and Scales: Integrated load indicator systems ensure safe lifting by displaying real-time weight measurements and preventing overload situations.

6. Custom Trolleys: Trolleys can be tailored for specific applications, whether it’s a motorized trolley for smooth, automatic movement or specialized designs for handling unique load shapes and sizes.

7. Safety Features: Incorporate safety enhancements such as limit switches, emergency stop buttons, and anti-drop devices, ensuring secure operation and minimizing the risk of accidents.

8. Material Choices: Custom manufacturing options include using stainless steel or galvanized components for superior corrosion resistance, making the crane suitable for harsh environments or cleanroom applications.

9. Load Spreader Bars: Add load spreader bars to distribute weight evenly, preventing load damage and increasing lifting stability.

Customization and upgrading of a 1-ton gantry crane can substantially extend its capabilities, ensuring it meets specific operational demands and enhances overall productivity and safety.

List Quality Control and The Manufacturing Process of “1 ton gantry crane”

Manufacturing Process of 1 Ton Gantry Crane

1. Design and Engineering:

– Initial design and specifications are created using advanced CAD software.

– Load calculations and structural analysis ensure the crane can handle required loads safely.

2. Material Selection:

– High-quality steel and materials are chosen for durability and safety.

– Each batch of materials undergoes chemical and physical testing for compliance with quality standards.

3. Cutting and Fabrication:

– Steel plates and profiles are cut to size using CNC cutting machines.

– Components are fabricated by welding and forming. Automated welding robots ensure precision and consistency.

4. Machining:

– Precision machining of components like the hoist mechanism and trolley wheels.

– Machining processes are monitored to ensure dimensional accuracy.

5. Assembly:

– Components are assembled into sub-assemblies such as the hoist, trolley, and beams.

– Electrical systems and controls are integrated, including wiring and circuit board assembly.

6. Surface Treatment:

– Assembled parts undergo sandblasting and anti-corrosion surface treatment.

– Finishing with industrial-grade paint to enhance durability and appearance.

Quality Control Processes

1. Initial Inspection:

– Raw materials and components are inspected on arrival for compliance with specifications.

– Certificates of compliance and test reports are verified.

2. In-Process Monitoring:

– Continuous inspection during manufacturing to check dimensions, welding quality, and assembly alignment.

– Use of calibrated measuring instruments and gauges.

3. Non-Destructive Testing (NDT):

– Techniques like ultrasonic testing, magnetic particle inspection, and radiography ensure weld integrity.

4. Load Testing:

– Assembled crane undergoes load tests to verify lifting capacity and structural integrity.

– Overload tests simulate worst-case scenarios to ensure safety margins.

5. Final Inspection:

– A comprehensive inspection of final assembly for fit, finish, and functionality.

– Electrical systems are tested, including emergency stop and limit switches.

6. Documentation and Certification:

– Compilation of test reports, inspection records, and certificates.

– Issuance of a quality certification confirming compliance with industry standards.

By following a rigorous manufacturing process and stringent quality control measures, 1-ton gantry cranes are ensured to be safe, reliable, and efficient for industrial use.

How to use “1 ton gantry crane”

Operating a 1-ton gantry crane involves several critical steps to ensure safety and efficiency. Here’s a concise guide:

Pre-Operation

1. Inspection:

– Check the crane structure, wheels, and hoist for any signs of damage or wear.

– Ensure all safety labels and load capacity indicators are visible and legible.

– Verify that the area is clear of obstructions and has a stable, level surface.

2. Setup:

– Position the gantry crane over the load, ensuring the wheels are locked if the crane is on a mobile frame.

– Adjust the height if the crane is adjustable and lock it securely.

Operation

1. Hoisting:

– Attach the load securely using appropriate lifting slings and load hooks.

– Ensure the load is balanced and secure before lifting.

– Use the hoist control to lift the load gently. Avoid jerky movements.

2. Moving the Load:

– If the crane is mobile, unlock the wheels and push the gantry crane to the desired location.

– Move slowly and steadily to avoid swinging the load.

– For fixed-position cranes, use the trolley to move the load horizontally along the beam.

3. Lowering the Load:

– Position the load over the drop location.

– Lower the load slowly using the hoist control.

– Ensure the load is stable and properly positioned before releasing the slings.

Post-Operation

1. Securing:

– Detach slings/hooks and store them properly.

– Lock the wheels if the crane is mobile.

– Perform a final inspection to ensure no parts are damaged.

– Store the crane in its designated area if it’s not permanently fixed.

Safety Tips

– Always follow the manufacturer’s instructions.

– Do not exceed the crane’s load capacity.

– Avoid sudden or jerky movements.

– Ensure all operators are trained and aware of emergency procedures.

“1 ton gantry crane” Comparative Analysis

A 1-ton gantry crane is a versatile lifting device employed in various industries to handle loads up to 1 ton (2,000 pounds). For a comparative analysis, several factors need to be considered: material, adjustability, portability, and intended use.

Material

Aluminum vs. Steel

– Aluminum: Lightweight, corrosion-resistant, and easier to maneuver. Ideal for mobile applications or environments where portability is key.

– Steel: More robust and durable, suitable for heavy-duty applications. Typically more stable and can withstand harsher environments.

Adjustability

Fixed Height vs. Adjustable Height

– Fixed Height: Simplifies operation, sturdy construction. Effective for repeated tasks at consistent heights.

– Adjustable Height: More versatile, accommodates different tasks and environments. Preferred in workshops with varying lifting needs.

Portability

Stationary vs. Mobile

– Stationary: Permanently installed, offering maximum stability. Common in production lines or warehouses with fixed layouts.

– Mobile: Equipped with wheels for easy movement. Ideal for tasks that require crane repositioning. However, they may have limited lifting heights due to base stability constraints.

Intended Use

Industrial vs. Commercial

– Industrial Use: Often requires robust construction, high durability, and sometimes additional features like motorized movement.

– Commercial Use: Generally lighter, more cost-effective, and suitable for less demanding applications.

Cost-Benefit Analysis

Entry-Level vs. Premium Models

– Entry-Level: Economical, suitable for small businesses or occasional use. Typically offers fewer features and lower durability.

– Premium Models: Higher upfront cost, but increased longevity, additional features, and more efficient performance. Best for frequent, intensive use.

Conclusion

Choosing a 1-ton gantry crane depends on specific needs: material for weight and corrosion resistance, adjustability for flexibility, and portability for mobility. For high-frequency, rigorous tasks, a steel, fixed-height, stationary crane offers durability and stability. Conversely, for diverse, mobile requirements, an adjustable, aluminum, mobile crane is advantageous. Balancing these factors against budget constraints will determine the best fit for operational efficiency.

“1 ton gantry crane” Warranty and Support

Warranty and Support for 1 Ton Gantry Crane

Our 1 Ton Gantry Cranes are backed by a comprehensive warranty, ensuring peace of mind and reliable performance for all our customers. The warranty covers all parts and manufacturing defects for a period of one year from the date of purchase. This includes coverage for structural components, electrical systems, and mechanical parts, ensuring that any issues arising from normal use are swiftly addressed and resolved.

In addition to the standard one-year warranty, we offer extended warranty options. These extensions can be customized based on your operational needs, providing additional coverage for up to three years. Extended warranties include the same comprehensive coverage as the standard warranty, offering extended protection for critical components and systems.

Our support services are designed to provide assistance throughout the lifespan of your gantry crane. We offer 24/7 customer support via phone and email, ensuring that expert help is always available. Our team of knowledgeable technicians can assist with troubleshooting, maintenance advice, and operational tips to ensure your crane remains in optimal condition.

For more complex issues, we provide on-site service and repair. Our network of certified technicians can be dispatched promptly to diagnose and repair any problems, minimizing downtime and ensuring that your operations can continue smoothly. Additionally, we offer routine maintenance packages to keep your gantry crane in top working order, preventing potential issues before they arise.

To access warranty and support services, simply contact our dedicated customer service team with your crane’s serial number and purchase details. We are committed to providing exceptional support and service, helping you maximize the efficiency and lifespan of your 1 Ton Gantry Crane.

List “1 ton gantry crane” FAQ

1 Ton Gantry Crane FAQ

1. What is a 1 Ton Gantry Crane?

A 1-ton gantry crane is a lightweight, portable lifting device designed to move loads up to 1 ton (2,000 pounds). It’s commonly used in workshops, warehouses, and maintenance areas for lifting and transporting materials within a confined space.

2. What are the key components of a 1 Ton Gantry Crane?

Key components include the horizontal I-beam (or girder), two vertical A-frame legs, caster wheels (for mobility), a hoist (manual or electric), and a trolley that travels along the I-beam.

3. What types of 1 Ton Gantry Cranes are available?

There are several types, including adjustable height, fixed height, and portable gantry cranes. Each type is tailored to specific needs in terms of lifting height and mobility.

4. How is a 1 Ton Gantry Crane operated?

The crane is typically operated using a hoist that can either be manual (hand chain) or electric. The hoist and trolley travel along the I-beam, allowing horizontal movement of the load. The crane itself can usually be moved along a surface via its caster wheels.

5. Are there safety standards a 1 Ton Gantry Crane must meet?

Yes, these cranes must adhere to standards set by organizations such as OSHA (Occupational Safety and Health Administration) and ANSI (American National Standards Institute), ensuring their safe design and operation.

6. Can a 1 Ton Gantry Crane be used outdoors?

Yes, but it requires weather-resistant materials and coatings. Additionally, ensure the ground is level and sturdy enough to support the crane and its load.

7. What are the installation requirements?

Installation is straightforward for portable models, requiring no permanent fixtures. Ensure the surface is level, and follow the manufacturer’s assembly guidelines.

8. How do you maintain a 1 Ton Gantry Crane?

Regular inspection, lubrication of moving parts, checking for wear and tear, and ensuring all components are securely fastened are essential for maintenance.

9. What is the cost range for a 1 Ton Gantry Crane?

The cost varies depending on features, ranging from a few hundred to several thousand dollars.

10. Where can I buy a 1 Ton Gantry Crane?

They are available through industrial equipment suppliers, online marketplaces, and specialized material handling equipment providers.

Top 10 FAQ with answer about 1 ton gantry crane for Buyer Sourcing from China

Sure! Here are the top 10 frequently asked questions (FAQ) about sourcing a 1-ton gantry crane from China, complete with concise answers:

1. Q: What is a 1-ton gantry crane?

A: A 1-ton gantry crane is a type of crane with a rated lifting capacity of 1 ton, typically used for lifting and moving heavy objects in workshops, warehouses, and construction sites.

2. Q: What materials are commonly used for gantry cranes?

A: Gantry cranes are typically made from steel due to its strength and durability. Some models can also incorporate aluminum for lighter weight and corrosion resistance.

3. Q: What are the key specifications to consider?

A: Important specifications include lifting capacity (1 ton), lifting height, span, overall height, beam length, and power supply requirements.

4. Q: How do I verify the quality of a 1-ton gantry crane from China?

A: Look for certifications such as CE, ISO, and SGS. Additionally, request a quality inspection report, check the manufacturer’s credentials, and read customer reviews.

5. Q: What is the typical lead time for manufacturing and delivery?

A: Lead times can vary but generally range from 4 to 12 weeks, depending on the manufacturer’s workload and customization requirements.

6. Q: What customization options are available?

A: Common customizations include adjustable height, spans, adding motorized trolleys, and specific color coatings. Customizations can be discussed directly with the manufacturer.

7. Q: How is shipping handled, and what are the costs?

A: Shipping costs depend on the size, weight, and destination of the crane. Manufacturers typically offer FOB (Free on Board) pricing, and the buyer can arrange sea or air freight.

8. Q: What type of warranty is offered?

A: Warranties usually range from 1 to 2 years. Ensure to understand what the warranty covers, including parts, labor, and onsite support.

9. Q: Are spare parts readily available?

A: Most reputable manufacturers provide spare parts readily. It’s advisable to confirm the availability and the lead time for spare parts before purchasing.

10. Q: What after-sales support is provided?

A: After-sales support can include installation guidance, training, maintenance services, and technical support. Confirm the details with your supplier.