5 ton gantry crane Safety Certifications

Operating a 5-ton gantry crane requires adherence to various safety standards and certifications to ensure safe and reliable use. Key certifications and standards include:

1. OSHA Compliance: In the United States, the Occupational Safety and Health Administration (OSHA) sets forth regulations (29 CFR 1910.179) for the safe operation of overhead and gantry cranes. Compliance is mandatory for workplace safety.

2. ANSI/ASME B30.2: This standard by the American Society of Mechanical Engineers (ASME) provides safety guidelines related to the design, inspection, maintenance, and operation of overhead and gantry cranes.

3. CMAA Specification 70: The Crane Manufacturers Association of America’s Specification 70 outlines the requirements for cranes, including structural, mechanical, and electrical components. Adhering to this specification ensures the crane meets high-quality standards.

4. ISO 9001 & ISO 14001: ISO 9001 focuses on quality management systems, ensuring cranes are manufactured to high-quality standards. ISO 14001 is related to environmental management, ensuring environmentally responsible manufacturing processes.

5. Load Testing Certification: Regular load testing (typically 125% of the crane’s rated capacity) verifies the crane’s ability to handle loads safely. This should be done by certified professionals and documented.

6. Inspection and Maintenance Records: Regular inspection and maintenance are mandated. Compliance with standards like OSHA 1910.179(j) ensures thorough documentation of inspections, repairs, and maintenance.

7. Operator Certification: Crane operators need to be certified through accredited programs like those provided by the National Commission for the Certification of Crane Operators (NCCCO). Certification ensures operators are knowledgeable about safety protocols and operational procedures.

Meeting these certifications and standards not only ensures regulatory compliance but also enhances workplace safety, reduces downtime, and extends the service life of the gantry crane. Regular training, maintenance, and adherence to these standards are essential for safe crane operation.

List Reference Technical Parameters of “5 ton gantry crane”

A 5-ton gantry crane is a versatile lifting solution widely used in warehouses, workshops, and construction sites. Here are the key reference technical parameters for a typical 5-ton gantry crane:

1. Load Capacity: 5 Tons (5000 kg)

2. Span Length: The distance between the two legs, typically ranging from 5 to 20 meters, depending on the model and application.

3. Lifting Height: The maximum height at which the crane can lift the load. Commonly ranges between 3 to 12 meters.

4. Crane Speed:

– Hoisting Speed: Usually between 4 to 8 meters per minute.

– Cross Travel Speed: Typically ranges from 2 to 20 meters per minute.

– Long Travel Speed: Can vary from 15 to 40 meters per minute.

5. Power Supply: Generally, a 3-phase AC power supply is used, with common voltages being 220V, 380V, or 440V based on regional standards.

6. Motor Power: Varies based on the operational speeds and mechanisms, but commonly ranges between 3 to 10 kW.

7. Control Method: Includes options like pendant control, remote control, or cabin control, offering flexibility and safety based on specific needs.

8. Beam Type: Typically comes in single-girder or double-girder configurations. Single-girder is more common for lighter applications, while double-girder offers enhanced stability and capacity.

9. Duty Class/Service Class: Defined by usage frequency and load intensity. Common classifications include A3 (light duty) to A5 (medium duty), per FEM/DIN standards.

10. Wheelbase: The distance between the wheels, which impacts stability and ease of movement; generally in the range of 3 to 10 meters.

11. Safety Devices: Includes limit switches, overload protection, emergency stop, anti-collision systems, and buffer devices to ensure safe operations.

Understanding these parameters helps in selecting the suitable model based on operational requirements, ensuring safety, efficiency, and durability in lifting operations.

List Product features of “5 ton gantry crane”

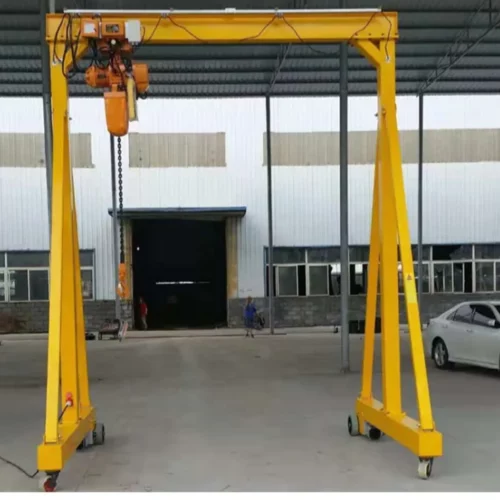

A 5-ton gantry crane is a versatile piece of lifting equipment commonly used in industries such as manufacturing, warehousing, and construction. Here are some of the key features:

1. Load Capacity: Capable of lifting and transporting loads up to 5 tons, making it suitable for medium to heavy-duty applications.

2. Adjustable Height: Many models come with adjustable height options to accommodate various load sizes and workplace environments.

3. Span Length: Typically features a customizable span length to fit different workspace widths.

4. Mobility: Often equipped with wheels or casters, allowing for easy relocation and flexibility within the workplace.

5. Construction Material: Usually built from high-quality steel, ensuring durability, stability, and a long lifespan.

6. Ease of Assembly: Designed for straightforward assembly and disassembly, promoting efficient setup and storage.

7. Lifting Mechanism: Can be equipped with either manual or motorized hoists, providing flexibility in operation based on specific needs.

8. Safety Features: Includes safety locks, overload protection, and emergency stop mechanisms to ensure safe operation.

9. Power Source: Options for electric or manual power operation, depending on the model and required usage.

10. Customization: Many models offer customization options for height, span, and additional features like cantilever ends for extended reach.

11. Control Options: Comes with different control methods, such as pendant controls, wireless remotes, or even integrated touch screen panels.

12. Weather Resistance: Some models are designed with weather-resistant coatings for outdoor use without compromising performance.

13. Compliance: Built to meet industry standards and regulations for safe and efficient operation.

14. Maintenance: Constructed to require minimal maintenance, reducing downtime and operational costs.

15. Portability: Lightweight designs available for easy transport and deployment across different job sites.

List Various Types of “5 ton gantry crane”

A 5-ton gantry crane is a versatile lifting device used in various industries for handling heavy loads. Here’s a brief overview of different types of 5-ton gantry cranes:

1. Fixed Height Gantry Crane:

– Description: This type of crane has a static height.

– Application: Ideal for applications where the lifting height requirements are constant.

2. Adjustable Height Gantry Crane:

– Description: The height can be adjusted to accommodate different lifting needs.

– Application: Useful in environments where varying heights are needed frequently.

3. Single Girder Gantry Crane:

– Description: Features a single girder with a trolley running on the bottom flange.

– Application: Suitable for lighter loads and shorter spans.

4. Double Girder Gantry Crane:

– Description: Utilizes two girders, which enhance strength and stability.

– Application: Used for heavier loads and longer spans.

5. Portable Gantry Crane:

– Description: Designed for mobility and can be moved to different locations.

– Application: Perfect for temporary or varied worksites.

6. Adjustable Span Gantry Crane:

– Description: The span (width) can be adjusted.

– Application: Offers flexibility for different workspace constraints.

7. Rubber-Tired Gantry Crane (RTG):

– Description: Equipped with rubber tires for easy movement.

– Application: Commonly used in outdoor environments like shipping yards.

8. Rail-Mounted Gantry Crane (RMG):

– Description: Runs on rails installed on the ground.

– Application: Used in fixed pathways in shipyards and container terminals.

9. Cantilever Gantry Crane:

– Description: Features extended cantilever arms for increased reach.

– Application: Ideal for working around obstacles or overhanging workspaces.

Each type of gantry crane offers unique advantages tailored to specific applications. Selecting the right crane depends on factors such as load requirements, workspace constraints, and mobility needs.

List Application of “5 ton gantry crane”

A 5-ton gantry crane is a versatile piece of material handling equipment utilized across various industries due to its moderate capacity and adaptability. Here are several applications:

1. Manufacturing Plants: Used to lift and transport heavy machinery, equipment, and materials, facilitating the assembly process and enhancing operational efficiency.

2. Construction Sites: Essential for moving building materials, structural components, and tools, aiding in tasks like setting up large pillars or beams and reducing manual labor.

3. Warehouses: Facilitates the handling of heavy inventory and goods, ensuring quick and efficient loading, unloading, and storage, thereby optimizing space and workflow.

4. Shipyards and Docks: Handles cargo loading and unloading from ships, including containers, heavy machinery, and large parts, contributing to improved maritime logistics.

5. Automotive Industry: Assists in the assembly and maintenance of vehicles by lifting engines, chassis, and other substantial components, thus ensuring precise and safe operations.

6. Railway Yards: Used for the maintenance and repair of trains, including lifting engines, rail cars, and other heavy train components, ensuring timely upgrades and safety checks.

7. Mining Operations: Aids in the lifting and transporting of heavy mining equipment, ores, and other materials, facilitating efficient mineral extraction and processing.

8. Workshops and Fabrication Shops: Crucial for the handling of heavy raw materials and fabricated parts, allowing precise movements for cutting, welding, and assembling components.

9. HVAC Installation: Facilitates the lifting and positioning of large HVAC units and systems during installation and maintenance, ensuring safety and efficiency.

10. Aerospace and Aviation: Supports the assembly, repair, and maintenance of aircraft by handling large parts and components, contributing to precise and safety-critical operations.

The 5-ton capacity makes this gantry crane ideal for tasks that require substantial but manageable lifting power, enabling diverse applications across various sectors.

List Buyer Types of “5 ton gantry crane”

Buyer types for a 5-ton gantry crane vary based on their specific needs, industry requirements, and operational capabilities. Below are the primary types of buyers who typically seek this equipment:

1. Manufacturing Plants: These facilities require 5-ton gantry cranes for handling and transporting raw materials and finished products within the plant. The crane provides flexibility and efficiency in moving heavy items around the production floor.

2. Construction Companies: Construction firms often use gantry cranes for lifting and positioning heavy construction materials, such as steel beams, concrete panels, and other large components, at various job sites.

3. Warehouses and Distribution Centers: These buyers utilize gantry cranes to move large, heavy cargo within their facilities, enhancing the efficiency of loading and unloading goods from trucks and storage areas.

4. Shipyards and Marine Operations: Shipyards and marine maintenance companies use 5-ton gantry cranes to handle ship parts, equipment, and other heavy materials required for shipbuilding, repairs, and maintenance tasks.

5. Metal Fabrication Shops: These buyers need gantry cranes to lift and position large metal sheets, beams, and fabricated parts for processing, welding, assembly, and storage.

6. Automotive Industry: Automotive plants and repair shops may use gantry cranes to move heavy engines, chassis, and other large car parts during manufacturing and repair processes.

7. Power Plants: Power plants might use gantry cranes for moving heavy equipment like transformers, turbines, and other machinery necessary for plant operations and maintenance.

8. Mining and Mineral Processing Operations: These buyers use gantry cranes to handle mining equipment, mineral ores, and processed materials within their sites.

9. Aviation Companies: In aviation, gantry cranes are employed for lifting aircraft parts, engines, and other heavy components during assembly, maintenance, and repairs in hangars and workshops.

10. Equipment Rental Companies: These companies purchase gantry cranes to rent out to various industries on a short-term or project-specific basis, providing a flexible solution for those who need them temporarily.

Each of these buyer types leverages the 5-ton gantry crane to optimize their material handling efficiency, safety, and overall productivity in their specific operations.

List “5 ton gantry crane” Project Types for Different Industries

A 5-ton gantry crane is a versatile lifting solution that finds applications across various industries. Here are project types for different sectors where a 5-ton gantry crane can be indispensable:

1. Manufacturing Industry:

– Assembly Lines: Used for moving heavy components between workstations efficiently.

– Tooling and Machining: Ideal for lifting and positioning large machine parts, dies, and molds.

– Maintenance and Repair: Facilitates maintenance by lifting heavy machinery and industrial parts.

2. Construction Industry:

– Material Handling: Transports large construction materials like steel beams and concrete blocks.

– Site Preparation: Assists in the movement of heavy equipment and resources around construction sites.

– Modular Construction: Supports assembling and disassembling modular units, enhancing speed and safety.

3. Warehousing and Logistics:

– Inventory Management: Effective for handling large, bulky items during loading and unloading processes.

– Container Handling: Moves heavy containers and pallets efficiently, optimizing storage space.

– Distribution Centers: Enhances picking processes by easily moving large quantities of goods.

4. Automotive Industry:

– Vehicle Assembly: Used in various stages of vehicle assembly for lifting engines, chassis, and other bulky components.

– Parts Manufacturing: Assists in handling large metal presses, molds, and finished parts.

– Maintenance Shops: Essential for heavy lifting tasks such as engine removal and installation.

5. Shipbuilding and Marine Industry:

– Dry Docks: Helps in the installation and removal of heavy parts such as engines and propellers.

– Ship Construction: Facilitates the maneuvering of large ship sections and materials during assembly.

– Pier Maintenance: Useful for lifting heavy equipment and supplies onto vessels.

In summary, a 5-ton gantry crane is a critical asset across diverse industries—from manufacturing and construction to warehousing, automotive, and shipbuilding—enhancing operational efficiency, safety, and productivity.

5 ton gantry crane Accessories Upgrades and Custom Manufacturing Options

Certainly! Upgrading a 5-ton gantry crane can enhance its performance, safety, and versatility. Here are some key accessories and custom manufacturing options to consider:

Accessories:

1. Wireless Remote Controls:

– Enable precise operation from a safe distance.

2. Motorized Trolleys:

– Improve load handling efficiency with powered movement.

3. Variable Speed Drives:

– Offer smoother operation and better control.

4. Safety Lights and Alarms:

– Enhance workplace safety with visual and audible alerts.

5. Load Indicators:

– Provide real-time load data to avoid overloading.

Upgrades:

1. Anti-Collision Systems:

– Reduce the risk of accidents between multiple gantries or nearby structures.

2. Extended Span or Height:

– Customize the crane to meet specific operational needs.

3. Automation & IoT Integration:

– Implement advanced control systems for remote monitoring and predictive maintenance.

4. Weather Protection:

– Include waterproofing and corrosion-resistant materials for outdoor use.

Custom Manufacturing Options:

1. Non-Standard Dimensions:

– Fabricate to unique sizes and configurations tailored to specific site constraints.

2. Specialized Attachments:

– Design hooks, slings, or grapples for handling unique loads.

3. Enhanced Mobility:

– Add rail or track systems for easier movement across different sections.

4. Ergonomic Controls:

– Develop user-friendly interfaces to reduce operator fatigue.

Summary:

Enhancing a 5-ton gantry crane with modern accessories, advanced upgrades, and custom manufacturing options can significantly increase its utility and safety. From wireless remote controls and motorized trolleys to specialized attachments and IoT integration, these improvements can tailor the crane to your specific operational needs and improve overall efficiency.

List Quality Control and The Manufacturing Process of “5 ton gantry crane”

Quality Control of 5 Ton Gantry Crane

1. Design Review and Standards Compliance: Ensuring the design adheres to industry standards (like ISO, ANSI).

2. Material Inspection: Verifying the quality of raw materials through certifications and physical inspections.

3. In-Process Quality Checks: Regular inspections during different manufacturing stages to identify and rectify defects.

4. Welding Verification: Using non-destructive testing (NDT) methods to check weld integrity.

5. Dimensional Accuracy: Precision measurements to ensure all components fit correctly.

6. Load Testing: Conducting rigorous load tests to certify the crane’s lifting capacity and safety.

7. Final Inspection: Comprehensive review to verify assembly, functionality, and safety features.

8. Documentation and Traceability: Maintaining detailed records for future reference and traceability.

Manufacturing Process of 5 Ton Gantry Crane

1. Design and Engineering:

– Develop detailed blueprints and models.

– Perform structural simulations to ensure reliability.

2. Material Procurement:

– Acquire high-quality steel, motors, and electrical components.

– Conduct material inspections to verify standards.

3. Cutting and Fabrication:

– Laser cutting or machining of steel components.

– Welding and joining components per design specifications.

4. Machining:

– Precision machining of vital components (gears, pulleys).

– Ensuring consistency through CNC machines.

5. Welding and Assembly:

– Skilled welding of structural components.

– Fabricating the crane’s main frame, legs, and beams.

6. Surface Treatment:

– Sandblasting to remove impurities.

– Applying anti-corrosion coatings (paint, galvanization).

7. Electrical Installation:

– Integrating motors, control panels, and wiring.

– Ensuring compliance with electrical safety standards.

8. Assembly and Integration:

– Assembling the entire crane structure.

– Installing hoist mechanisms and control systems.

9. Testing and Calibration:

– Load testing to verify lifting capacity and safety.

– Calibrating control systems for precision.

10. Final Inspection:

– Comprehensive check to ensure all components function correctly.

– Addressing any defects before dispatch.

11. Packaging and Shipping:

– Securely packaging components for transportation.

– Ensuring all parts are labeled and documented.

This streamlined process ensures the 5 ton gantry crane meets all quality and safety standards, providing reliable performance in industrial applications.

How to use “5 ton gantry crane”

Using a 5-ton gantry crane can be straightforward if you follow these essential steps:

Setup

1. Inspection: Before use, inspect the crane for any visible damage or wear. Check the cables, hooks, and trolley.

2. Positioning: Place the gantry crane on a flat, stable surface. Ensure the area is clear of obstructions.

3. Securing: Engage the wheel locks or outriggers if the crane is mobile to prevent unwanted movement.

Operation

1. Load Attachment:

– Hook: Secure the load using appropriate lifting tackles (straps, chains). Ensure it is properly balanced.

– Latch: Close the safety latch on the hook to prevent slippage.

2. Lifting:

– Control: Use the control pendant or remote to hoist the load slowly. Keep an eye on the load, ensuring it lifts evenly.

– Height: Raise the load just enough to clear obstacles.

Movement

1. Horizontal Movement:

– Move the load by sliding the trolley along the beam.

– Use manual force or power-driven trolley systems as available.

2. Vertical Movement:

– Adjust the load height as needed while moving. Always keep it within a safe height range.

3. Travel:

– If the crane needs to move, ensure the path is clear. Unlock the wheels and push/pull the gantry crane to its new position.

Safety Tips

– Stay Alert: Continually monitor for any signs of stress on the equipment.

– Limit Load: Never exceed the crane’s 5-ton capacity.

– Clear Area: Ensure no one is under the load while lifting or moving it.

– Emergency Stop: Be aware of emergency stop procedures.

Shutdown

1. Lower Load: Gently lower the load to the designated place.

2. Secure Crane: Lock wheels and disengage controls.

3. Inspect: Post-use inspection helps ensure longevity and safety.

By following these steps, you can use the 5-ton gantry crane efficiently and safely.

“5 ton gantry crane” Comparative Analysis

A 5-ton gantry crane is a versatile lifting device widely used in various industries, including manufacturing, construction, and warehousing. To determine the best option, comparing key attributes such as design, mobility, installation, cost, and safety features is crucial.

Design and Construction: Gantry cranes typically come in three designs: fixed, semi-gantry, and portable. Fixed gantry cranes are robust and ideal for repetitive lifting in a specific area. Semi-gantry cranes offer more flexibility, with one side on a fixed rail and the other on wheels. Portable gantry cranes excel in versatility, being easily movable across different locations.

Mobility: Fixed and semi-gantry cranes are suited for environments with structured workflows, requiring lifting in predetermined zones. Portable gantry cranes, however, are more beneficial in dynamic settings where tasks or lifting points frequently change. The portability aspect is particularly advantageous in warehousing and temporary job sites.

Installation: Installation costs and complexity vary significantly. Fixed cranes usually demand substantial structural modifications, leading to higher initial costs and installation time. Semi-gantry cranes might offer some reduction in these requirements but still need a rail system setup. Portable cranes stand out with minimal installation requirements, often needing just assembly, thus reducing time and expenses.

Cost: Fixed gantry cranes generally incur higher initial and potential long-term maintenance costs due to structural dependencies. Portable cranes, despite possibly higher upfront costs for quality units, often prove more economical over time due to their flexibility and ease of relocation, reducing the need for multiple fixed installations.

Safety Features: All crane types must adhere to stringent safety standards, including overload protection, emergency stop features, and regular inspection protocols. Fixed cranes often feature more robust built-in safety mechanisms due to their permanent nature. However, modern portable cranes are increasingly equipped with advanced safety features to bolster safe operation.

Conclusion: The ideal 5-ton gantry crane choice depends on operational requirements. Fixed gantry cranes offer stability for static tasks, semi-gantry cranes provide balanced versatility, and portable gantry cranes present unmatched flexibility and lower long-term costs, making them suitable for dynamic work environments.

“5 ton gantry crane” Warranty and Support

When investing in a 5-ton gantry crane, understanding the warranty and support options is crucial for ensuring long-term performance and reliability. Most manufacturers offer a standard warranty that typically ranges from one to three years, covering defects in materials and workmanship. It’s essential to read the warranty terms carefully to understand what is included and excluded. For instance, the warranty might not cover wear and tear parts, misuse, and inadequate maintenance.

Extended warranties may also be available for an additional cost, providing peace of mind and protection beyond the standard period. These extended warranties often cover major components such as the hoist, electrical systems, and structural integrity.

Support services are equally important. The best manufacturers offer comprehensive support packages, including 24/7 customer service, routine maintenance schedules, and rapid response to emergency repairs. Access to qualified technicians and a well-stocked inventory of spare parts can significantly reduce downtime in case of failures.

Furthermore, some companies provide training for your staff to ensure proper and safe operation of the crane. This can include both on-site training and easy-to-understand manuals or digital resources. Remote diagnostics and monitoring services are also becoming more common, allowing for real-time issue detection and troubleshooting without immediate on-site intervention.

In summary, when purchasing a 5-ton gantry crane, prioritize manufacturers that offer robust warranties and comprehensive support services. This will ensure that your investment remains productive and minimizes downtime, ultimately contributing to operational efficiency and safety.

List “5 ton gantry crane” FAQ

5 Ton Gantry Crane FAQs

1. What is a 5 ton gantry crane?

A 5-ton gantry crane is a portable, wheeled lifting device designed to lift and transport heavy loads up to 5 tons. It consists of a horizontal beam (girder) supported by two A-frame legs on casters, allowing for mobility.

2. What are the typical applications?

These cranes are commonly used in manufacturing, warehouses, workshops, shipyards, and construction sites for material handling, assembly, and repair tasks.

3. What are the power options available?

Crane can be powered manually or electrically. Manual cranes leverage hand-pulled mechanisms, while electric cranes use motors for lifting and moving loads more efficiently.

4. What are the key features to consider when selecting a 5-ton gantry crane?

Important features include lifting capacity, height, span, wheel type, adjustability, and power source. Also, consider the environment where it will be used—indoor or outdoor.

5. How do I ensure the safety of the crane?

Regular inspections, adherence to load limits, proper training for operators, and maintenance of all parts are essential. Safety features like limit switches and emergency stop buttons enhance safety.

6. What are the installation requirements?

Installation involves positioning the crane on a flat, stable surface and ensuring that all bolts and connections are secure. Some models may require assembly of the frame and beam.

7. Are gantry cranes customizable?

Yes, many manufacturers offer customization options such as adjustable height, span, and additional accessories like motorized trolleys and remote controls.

8. What maintenance does a 5 ton gantry crane require?

Routine maintenance includes checking for wear and tear, lubricating moving parts, inspecting electrical systems, and ensuring that safety devices are functioning correctly.

9. What industries benefit the most from using 5-ton gantry cranes?

Industries like automotive, aerospace, metal fabrication, logistics, and shipbuilding gain significant efficiency and flexibility by using these cranes.

10. What is the lifespan of a typical 5-ton gantry crane?

With proper maintenance, a 5-ton gantry crane can last up to 20 years or more, depending on usage and environmental conditions.

This compact FAQ should offer a clear understanding of 5-ton gantry cranes, aiding in informed decision-making for potential buyers.

Top 10 FAQ with answer about 5 ton gantry crane for Buyer Sourcing from China

Certainly! Below are the top 10 frequently asked questions (FAQs) about sourcing a 5-ton gantry crane from China, along with concise answers:

1. What is the delivery time for a 5-ton gantry crane from China?

– The delivery time typically ranges from 30 to 60 days, depending on manufacturing schedules and shipping logistics.

2. What certifications are required and provided with the crane?

– Common certifications include CE, ISO, and sometimes CCC. Ensure the supplier provides these to comply with international standards.

3. Can I customize the gantry crane according to my specific needs?

– Yes, most manufacturers offer customization options for height, span, and additional features like anti-sway technology and wireless controls.

4. What is the warranty period for a 5-ton gantry crane?

– Warranties typically range from 12 to 24 months. Confirm the warranty period and what it covers with your supplier.

5. What are the typical payment terms when sourcing from China?

– Standard terms include a 30% deposit upon order confirmation and the remaining 70% before shipping. Some suppliers may offer flexible terms.

6. What shipping methods are available, and what are the associated costs?

– Shipping methods include sea freight (most common), air freight, and rail. Costs vary based on method, destination, and volume.

7. How do I ensure the quality of the gantry crane before finalizing the purchase?

– Perform a factory audit, request third-party inspection reports, and ask for testing videos or visit the factory to inspect the crane.

8. Do you provide installation and training services?

– Many suppliers offer installation guidance and training services, either via on-site technicians or detailed manuals and videos.

9. What after-sales services are available?

– After-sales services typically include technical support, spare parts supply, and sometimes remote troubleshooting. Verify the provider’s after-sales support.

10. How do I handle spare parts and maintenance?

– Ensure a steady supply of critical spare parts from the manufacturer or identify local suppliers. Some Chinese suppliers offer ongoing maintenance support.

By considering these FAQs, you can make a more informed decision when sourcing a 5-ton gantry crane from China.