Sure! Here’s a concise FAQ for sourcing crane operation services from SourcifyChina factory:

What types of cranes are available at SourcifyChina factory?

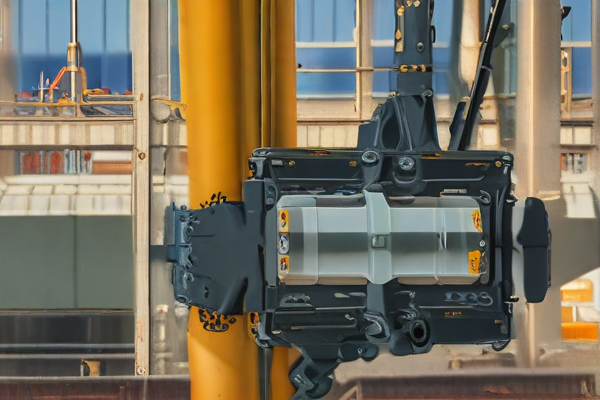

SourcifyChina offers a wide range of cranes including overhead cranes, gantry cranes, jib cranes, and tower cranes, each designed for specific industrial applications.

What is the lead time for ordering a crane?

The typical lead time for crane manufacturing and delivery ranges from 4 to 8 weeks, depending on the complexity and specifications of the order.

Can SourcifyChina customize cranes based on specific requirements?

Yes, SourcifyChina provides customization options to meet specific operational needs, including size, capacity, and additional features.

What are the quality standards followed by SourcifyChina for crane manufacturing?

SourcifyChina adheres to international quality standards such as ISO 9001 and complies with safety regulations to ensure high-quality and reliable crane operations.

Is installation and commissioning service available?

Yes, SourcifyChina offers comprehensive installation and commissioning services to ensure the cranes are set up and functioning correctly at your site.

What support services are available post-purchase?

Post-purchase support includes maintenance services, spare parts supply, and technical support to ensure optimal performance and longevity of the cranes.

How does SourcifyChina handle shipping and logistics?

SourcifyChina manages the entire logistics process, including packaging, shipping, and delivery to your specified location, ensuring a hassle-free experience.

Are training programs available for crane operators?

Yes, SourcifyChina offers training programs for crane operators to ensure safe and efficient use of the equipment.

What payment methods are accepted?

Accepted payment methods include wire transfer, letter of credit, and other common international payment options.

How can I request a quote or place an order?

You can request a quote or place an order by contacting SourcifyChina’s sales team via their official website, email, or phone.

This FAQ should provide a clear and concise overview of the key aspects of sourcing crane operation services from SourcifyChina. If you need more detailed information, you can always reach out directly to their customer service team.