Certainly! Here are the FAQs with answers:

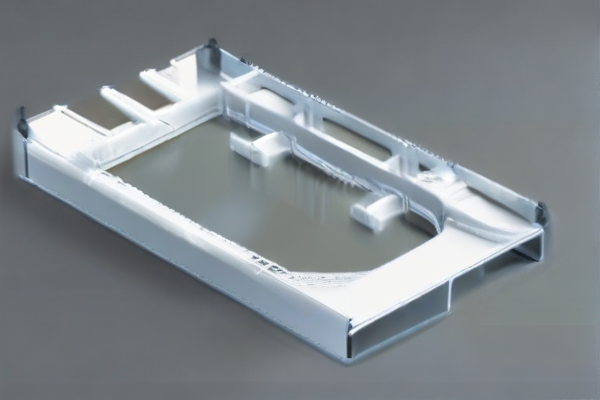

Q: What types of plastics does SourcifyChina factory specialize in for crane manufacturing?

A: SourcifyChina factory specializes in high-density polyethylene (HDPE), polypropylene (PP), and reinforced composite plastics tailored for crane components.

Q: How does SourcifyChina ensure the quality of plastic parts?

A: We implement rigorous quality control protocols, including material testing, dimensional accuracy checks, and durability assessments, to ensure all plastic parts meet industry standards.

Q: Are the plastics used by SourcifyChina environmentally friendly?

A: Yes, we prioritize using recyclable and sustainable plastic materials, and our manufacturing processes are designed to minimize environmental impact.

Q: Can SourcifyChina customize plastic parts for specific crane models?

A: Absolutely. We offer customized design and manufacturing services to meet the unique requirements of different crane models and applications.

Q: What is the typical lead time for manufacturing plastic crane parts?

A: The lead time varies depending on the complexity and quantity of the order, typically ranging from 4 to 8 weeks.

Q: Does SourcifyChina provide samples before mass production?

A: Yes, we provide prototype samples for approval to ensure the final product meets your specifications before commencing mass production.

Q: What certifications do SourcifyChina’s plastic products have?

A: Our plastic products are certified to meet international standards such as ISO 9001, CE, and RoHS, ensuring high quality and safety.

Q: How does SourcifyChina handle large volume orders?

A: We are equipped with advanced machinery and a robust supply chain, allowing us to efficiently manage and fulfill large volume orders without compromising quality.

Q: What are the payment terms for orders placed with SourcifyChina?

A: We offer flexible payment terms, including T/T (Telegraphic Transfer), L/C (Letter of Credit), and other arrangements upon discussion.

Q: How can I get a quote for my project?

A: You can request a quote by contacting us through our website or emailing our sales team with your project details, and we will provide a competitive estimate promptly.