Sure! Here are some FAQs with answers about the manufacturing of crane brake quality work from SourcifyChina factory:

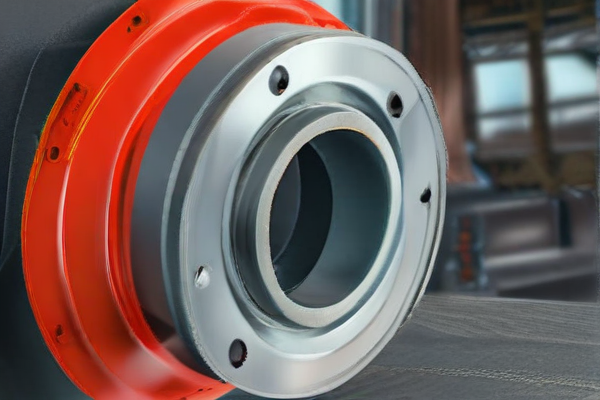

Q: What materials are used in the crane brakes manufactured by SourcifyChina factory?

A: SourcifyChina factory uses high-quality materials such as cast iron, steel, and composite friction materials to ensure durability, reliability, and optimal performance of crane brakes.

Q: How does SourcifyChina ensure the quality of their crane brakes?

A: SourcifyChina employs rigorous quality control measures including material testing, precision machining, and comprehensive performance tests to ensure every crane brake meets international standards and customer specifications.

Q: Are the crane brakes from SourcifyChina compliant with international standards?

A: Yes, the crane brakes are manufactured in compliance with international standards such as ISO, DIN, and ANSI, ensuring they meet global safety and performance requirements.

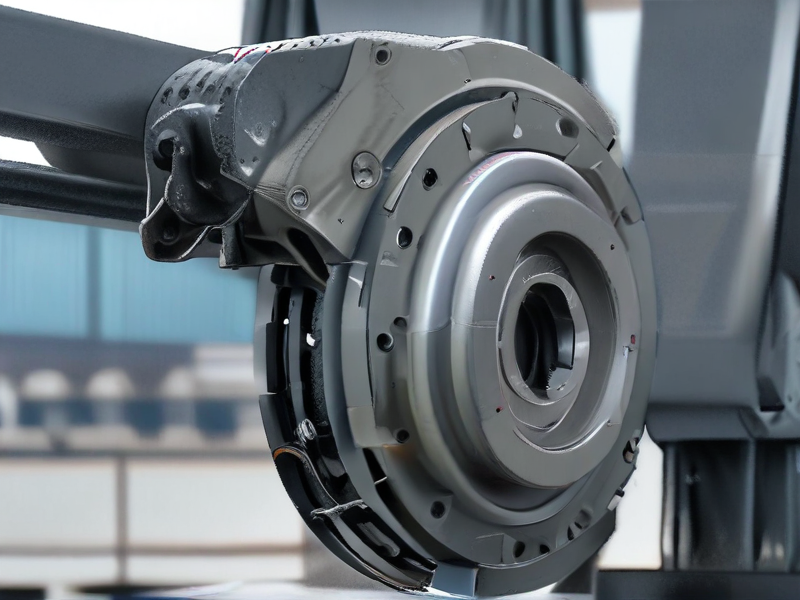

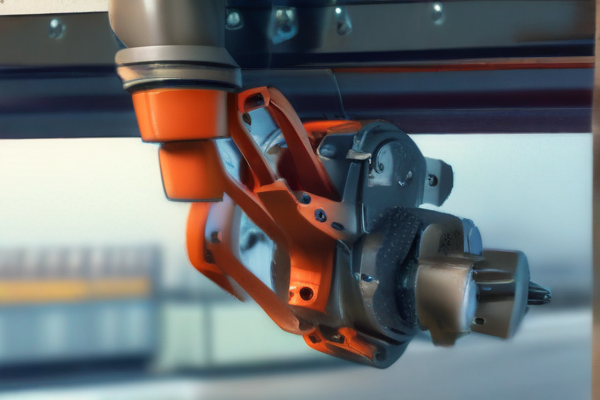

Q: What types of crane brakes does SourcifyChina produce?

A: SourcifyChina produces a variety of crane brakes including drum brakes, disc brakes, and electromagnetic brakes, catering to different types of cranes and operational needs.

Q: Can SourcifyChina provide customized crane brake solutions?

A: Absolutely, SourcifyChina offers customization services to meet specific requirements, including custom sizes, materials, and performance characteristics tailored to unique operational conditions.

Q: What is the typical lead time for an order from SourcifyChina?

A: The lead time varies based on order complexity and quantity, but typically ranges from 4 to 8 weeks. For urgent orders, expedited manufacturing options may be available.

Q: Does SourcifyChina offer after-sales support for their crane brakes?

A: Yes, SourcifyChina provides comprehensive after-sales support including installation guidance, maintenance tips, and troubleshooting assistance to ensure the longevity and efficiency of their crane brakes.

Q: How can I place an order with SourcifyChina?

A: Orders can be placed directly through SourcifyChina’s website, via email, or by contacting their sales team. They also offer consultation services to help determine the best brake solutions for your needs.

Q: What are the key advantages of choosing SourcifyChina for crane brakes?

A: The key advantages include high-quality manufacturing, compliance with international standards, customization options, competitive pricing, and excellent after-sales support.

Q: Does SourcifyChina provide warranty for their crane brakes?

A: Yes, SourcifyChina offers a warranty on their crane brakes, typically covering defects in materials and workmanship for a specified period, ensuring peace of mind for their customers.