Sure, here’s a concise FAQ for sourcing crane structures from SourcifyChina factory:

—

FAQ:

Sourcing Crane Structures from SourcifyChina Factory

1. What types of crane structures does SourcifyChina factory offer?

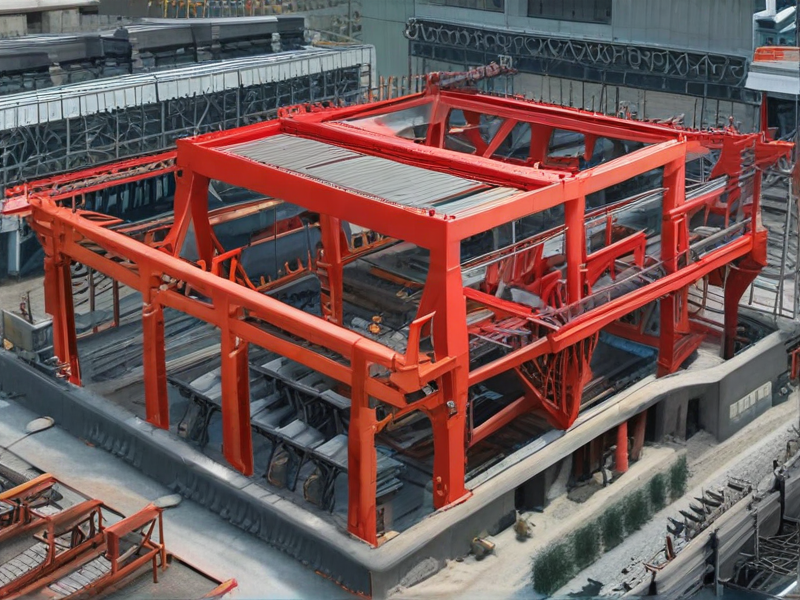

SourcifyChina factory offers a wide range of crane structures, including overhead cranes, gantry cranes, jib cranes, and tower cranes. They also provide custom designs based on specific project requirements.

2. How do I request a quote for a crane structure?

To request a quote, you can contact SourcifyChina via their website’s contact form or email. Provide details about the type of crane, specifications, and project requirements to receive an accurate quote.

3. What information should I provide for a custom crane design?

For a custom crane design, you should provide detailed project specifications, including load capacity, span, lifting height, working environment, and any special features required.

4. How long does it take to manufacture and deliver a crane structure?

The manufacturing and delivery time varies depending on the complexity of the crane structure and current production schedules. Typically, it takes 4-8 weeks for standard cranes and up to 12 weeks for custom designs.

5. What quality standards do SourcifyChina crane structures meet?

SourcifyChina ensures that their crane structures meet international quality standards such as ISO, CE, and other relevant certifications. They conduct rigorous quality checks throughout the manufacturing process.

6. Can I visit the factory for a site inspection?

Yes, SourcifyChina welcomes customers to visit their factory for a site inspection. You can schedule a visit by contacting their customer service team.

7. Does SourcifyChina provide installation and after-sales support?

Yes, SourcifyChina offers installation services and comprehensive after-sales support, including maintenance and spare parts supply.

8. What are the payment terms for ordering crane structures?

Payment terms typically include a down payment upon order confirmation and the balance before shipment. Specific terms can be negotiated based on the order size and customer relationship.

9. How do I ensure the crane structure meets my project requirements?

SourcifyChina works closely with clients to understand their needs and provide detailed technical drawings and specifications for approval before production begins.

10. Are there any warranties on the crane structures?

SourcifyChina offers warranties on their crane structures, usually covering defects in materials and workmanship for a specified period. Warranty terms are provided at the time of purchase.

—

This FAQ should provide a comprehensive overview for potential customers considering sourcing crane structures from SourcifyChina factory.