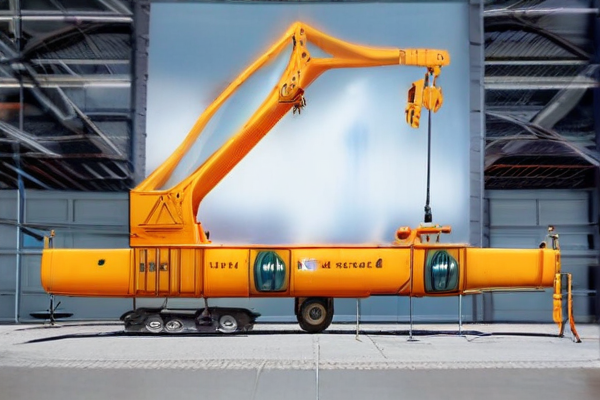

Sure! Here is a list of frequently asked questions (FAQ) with their answers regarding the manufacturing of Aircraft Maintenance Cranes by SourcifyChina factory.

Q1: What is the load capacity of the Aircraft Maintenance Cranes produced by SourcifyChina?

A1: SourcifyChina’s Aircraft Maintenance Cranes are designed with various load capacities ranging from 500 kg to 20 tons, catering to different aircraft maintenance needs.

Q2: Are the cranes compliant with international aviation safety standards?

A2: Yes, all cranes manufactured by SourcifyChina comply with international aviation safety standards, including ISO, OSHA, and IATA requirements, ensuring reliable and safe operations.

Q3: What materials are used in the construction of the cranes?

A3: The cranes are constructed using high-quality materials such as high-strength steel and aluminum alloys to ensure durability, robustness, and lightweight performance.

Q4: Can the cranes be customized according to specific requirements?

A4: Absolutely! SourcifyChina offers customization options to meet specific client requirements, including size, load capacity, and additional features.

Q5: What kind of after-sales support does SourcifyChina provide?

A5: SourcifyChina provides comprehensive after-sales support including installation assistance, training, maintenance services, and spare parts supply to ensure seamless operation.

Q6: How long is the warranty period for the cranes?

A6: The cranes come with a standard warranty period of 12 months from the date of installation, covering manufacturing defects and performance issues.

Q7: What is the lead time for manufacturing and delivery?

A7: The lead time depends on the customization level and order quantity, generally ranging from 4 to 12 weeks.

Q8: Can SourcifyChina handle international shipping?

A8: Yes, SourcifyChina has extensive experience in handling international shipping, ensuring timely and safe delivery to various global destinations.

Q9: How can I request a quote or place an order?

A9: You can request a quote or place an order by contacting SourcifyChina through their official website or by reaching out to their sales team via email or phone.

Q10: What quality control measures are in place during production?

A10: SourcifyChina adheres to strict quality control protocols, including material inspections, welding quality checks, and load testing to ensure each crane meets high-quality standards.