FAQ: Aluminum Gantry Cranes

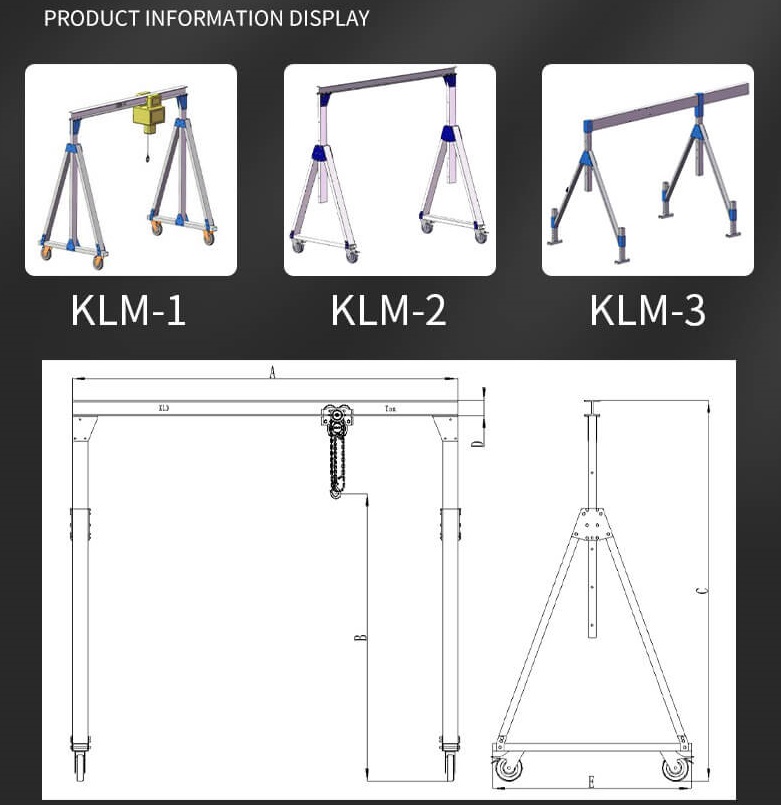

1. What is an aluminum gantry crane? An aluminum gantry crane is a lightweight, mobile lifting device made primarily from aluminum. It is designed for easy transportation and setup, making it ideal for applications requiring temporary or mobile lifting solutions, such as in workshops, warehouses, or construction sites.

2. What are the advantages of using an aluminum gantry crane? Aluminum gantry cranes offer several benefits including:

Lightweight: Aluminum is significantly lighter than steel, making these cranes easy to move and reposition.

Corrosion Resistance: Aluminum naturally resists corrosion, making it suitable for outdoor use or in environments with corrosive substances.

Adjustability: Many aluminum gantry cranes feature adjustable heights and spans to accommodate different lifting needs.

Ease of Assembly: These cranes can be quickly assembled and disassembled with minimal tools.

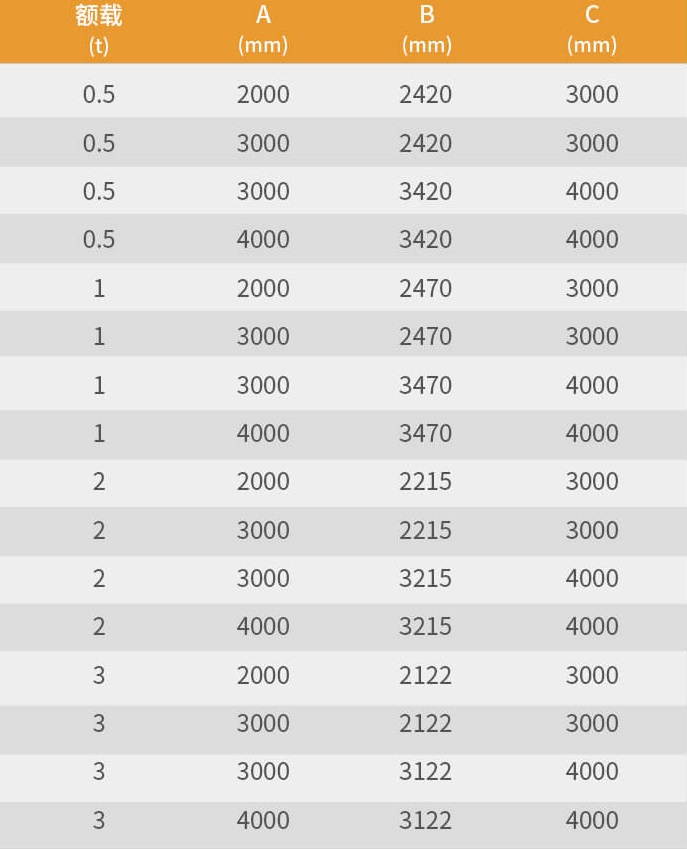

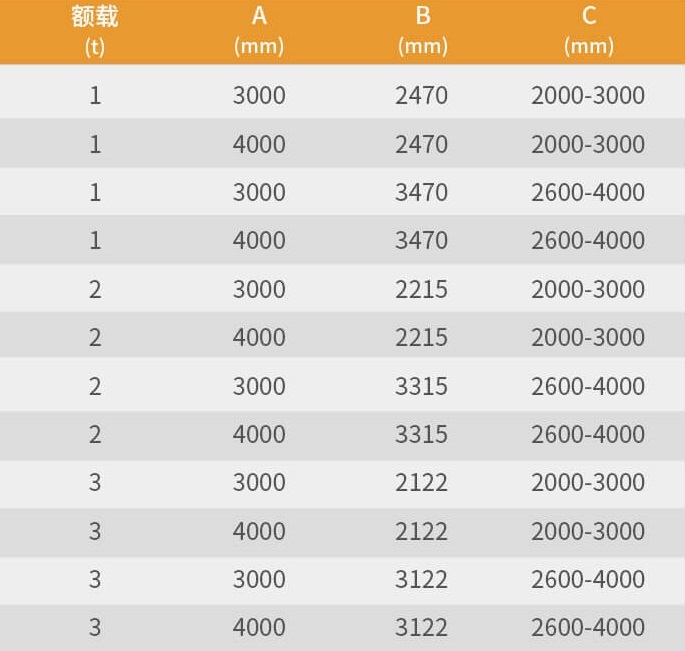

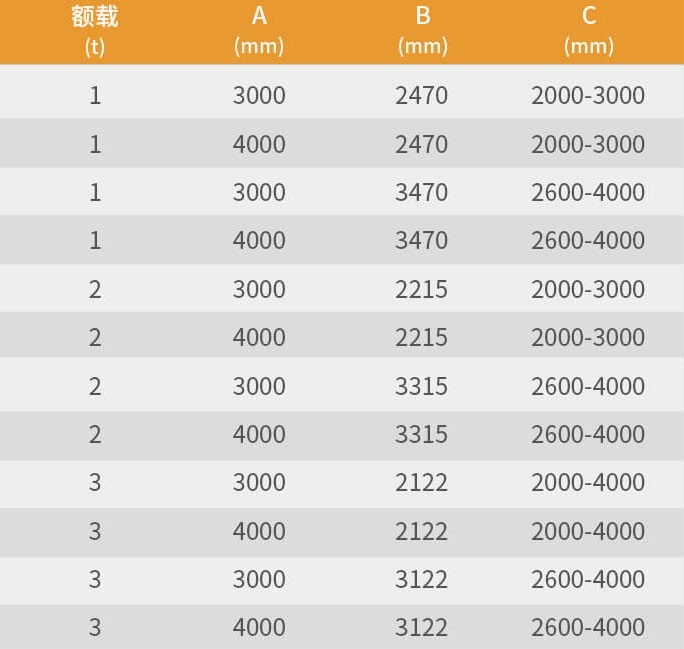

3. What are the typical load capacities of aluminum gantry cranes? Aluminum gantry cranes typically have load capacities ranging from a few hundred pounds up to 3 tons, depending on the design and model. It’s important to check the specific capacity for the model you consider to ensure it meets your lifting requirements.

4. Can aluminum gantry cranes be customized? Yes, many manufacturers offer customization options for aluminum gantry cranes, including adjustable spans, heights, and even the addition of motorized trolleys. Custom configurations can be designed to meet specific operational requirements.

5. How do I maintain an aluminum gantry crane? Maintenance for an aluminum gantry crane involves regular inspections to ensure all components are in good working order, lubrication of moving parts, and checking for signs of wear or damage. It’s also important to ensure that the crane is operated within its load capacity and environmental specifications to avoid overloading and environmental damage.

6. Are there any safety considerations specific to aluminum gantry cranes? When operating an aluminum gantry crane, it is crucial to adhere to all safety guidelines, such as:

Ensuring the crane is on a stable and level surface.

Never exceeding the rated capacity.

Regularly training operators on proper usage and safety procedures.

Using appropriate lifting accessories and checking them for damage before use.

7. Where can I purchase an aluminum gantry crane? Aluminum gantry cranes can be purchased from various industrial equipment suppliers and manufacturers. It’s advisable to buy from a reputable supplier that offers good after-sales support and warranty services.

8. How does the cost of an aluminum gantry crane compare to other types? Aluminum gantry cranes are generally more expensive than comparable steel models due to the cost of aluminum and its lightweight properties. However, the long-term benefits such as ease of movement, durability, and lower maintenance may justify the initial investment for many users.