Here is a list of frequently asked questions (FAQ) with answers about manufacturing Billet Handling Crane quality work from SourcifyChina factory:

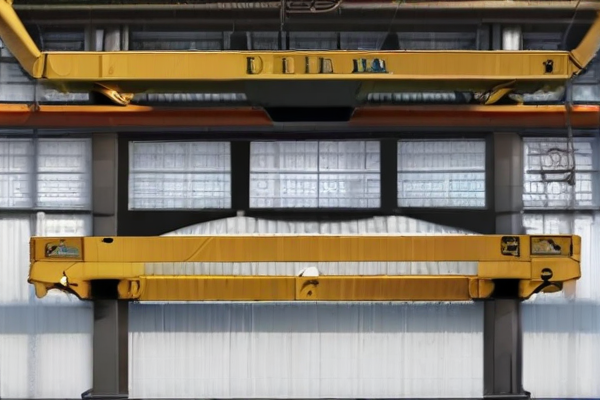

1. What type of cranes does SourcifyChina specialize in?

SourcifyChina specializes in manufacturing high-quality billet handling cranes, custom-engineered to meet the specific needs of our clients.

2. Are the billet handling cranes compliant with international safety standards?

Yes, our billet handling cranes are designed and manufactured in compliance with international safety standards, ensuring reliable and safe operation.

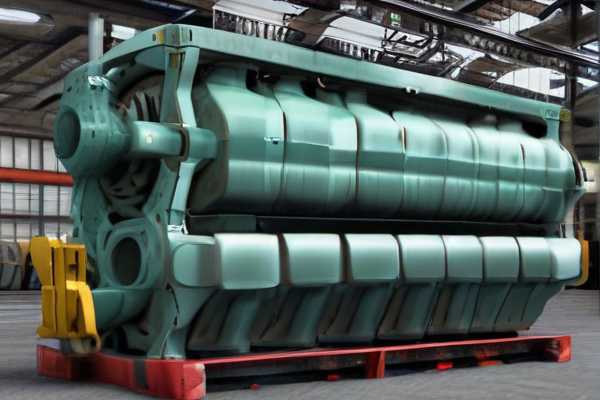

3. What materials are used for manufacturing billet handling cranes at SourcifyChina?

We use high-grade steel and other quality materials to ensure the structural integrity and longevity of our billet handling cranes.

4. How long does it take to manufacture a billet handling crane?

The manufacturing timeline typically ranges from 6 to 12 weeks, depending on the crane’s specifications and complexity.

5. Do you provide installation and commissioning services for your cranes?

Yes, we offer comprehensive installation and commissioning services to ensure seamless integration and optimal performance of our billet handling cranes.

6. Can SourcifyChina customize cranes according to specific client requirements?

Absolutely. We specialize in custom designs and can modify our billet handling cranes to meet the exact specifications and requirements of our clients.

7. What kind of after-sales support does SourcifyChina offer?

We provide extensive after-sales support, including maintenance, spare parts, and technical assistance to ensure the cranes operate efficiently throughout their lifespan.

8. How does SourcifyChina ensure the quality of its billet handling cranes?

We implement rigorous quality control measures at every stage of manufacturing, from material selection to final testing, to ensure our cranes meet the highest standards of performance and durability.

9. What are the payment terms for purchasing a crane from SourcifyChina?

Our standard payment terms are typically 30% advance payment and the balance before shipment. We are flexible and can discuss other arrangements to meet client needs.

10. How can I get a quotation for a billet handling crane from SourcifyChina?

You can contact us via our website or email us directly with your project details, and our sales team will provide you with a competitive quotation promptly.

This FAQ aims to answer some of the common questions about the quality work of billet handling cranes from SourcifyChina factory efficiently and succinctly.