Q1: What types of bridge construction cranes does SourcifyChina factory offer?

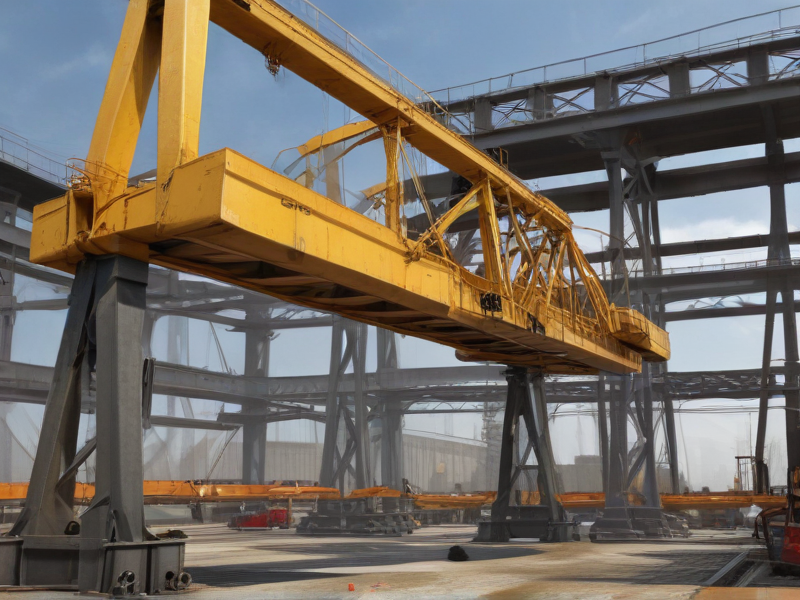

A: SourcifyChina factory offers a variety of bridge construction cranes, including overhead cranes, gantry cranes, and specialized segmental launching gantries. These cranes are designed to handle different construction requirements and load capacities.

Q2: What is the lead time for an order from SourcifyChina factory?

A: The lead time typically ranges from 6 to 12 weeks, depending on the crane’s specifications and customization requirements. It’s advisable to confirm specific lead times directly with the factory.

Q3: Can SourcifyChina factory customize cranes based on specific project needs?

A: Yes, SourcifyChina factory offers customization services. They can tailor the design, load capacity, and other features of the crane to meet your specific project requirements.

Q4: Are there any certifications for the quality of cranes produced by SourcifyChina factory?

A: Yes, cranes from SourcifyChina factory comply with international quality standards and are certified with ISO and CE certifications, ensuring reliability and safety.

Q5: Do they provide installation and after-sales support?

A: SourcifyChina factory provides comprehensive installation services and after-sales support, including maintenance, spare parts, and troubleshooting assistance.

Q6: What are the payment terms for ordering a crane from SourcifyChina factory?

A: The typical payment terms include a 30% advance payment for order confirmation and the remaining 70% before shipment. Payment methods can include wire transfer, L/C, and other agreed-upon terms.

Q7: How does SourcifyChina factory ensure the safety and reliability of their cranes?

A: SourcifyChina factory incorporates rigorous testing protocols and quality control measures. Their cranes are designed with advanced safety features and are subjected to extensive testing before delivery.

Q8: Is it possible to visit the factory before placing an order?

A: Yes, potential buyers are welcome to visit the SourcifyChina factory to inspect the manufacturing process, verify quality standards, and discuss project details.

Q9: What documentation is provided with the crane?

A: The factory provides comprehensive documentation, including user manuals, maintenance guides, installation instructions, and all necessary certification documents.

Q10: How can I get a quote for a bridge construction crane?