FAQ for Manufacturing Ceiling Crane Quality Work from SourcifyChina Factory

Q1: What materials are used in the construction of Ceiling Cranes?

A1: SourcifyChina uses high-grade steel and alloy components to ensure durability and strength. All materials undergo stringent quality checks to meet international standards.

Q2: How does SourcifyChina ensure the quality of Ceiling Cranes?

A2: Quality is assured through rigorous testing at multiple stages of production, including load testing, structural integrity checks, and compliance with ISO 9001 standards.

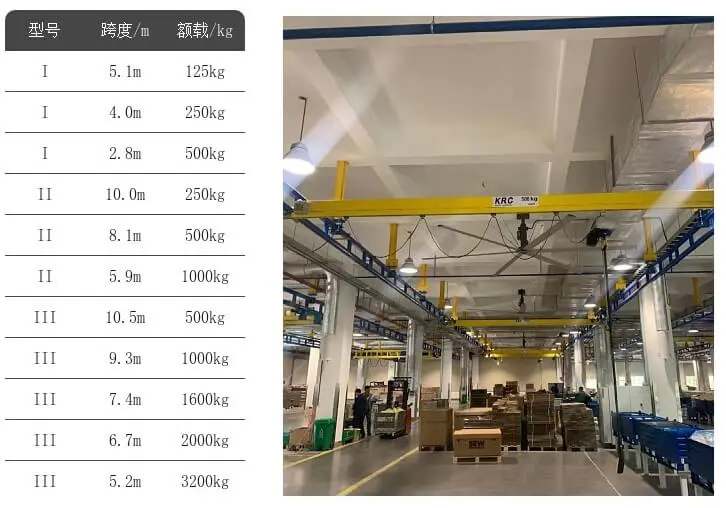

Q3: What are the load capacities available for Ceiling Cranes?

A3: Ceiling Cranes from SourcifyChina are available in various load capacities, ranging from 500 kg to 50 tons, customizable based on specific industrial needs.

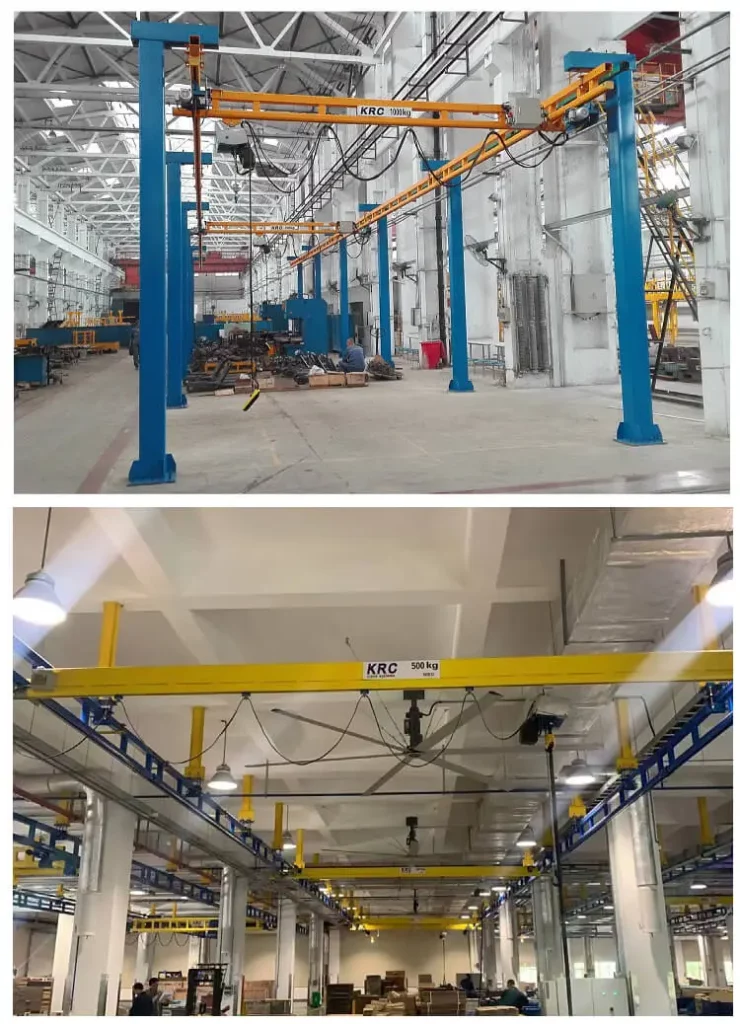

Q4: Can the Ceiling Cranes be customized?

A4: Yes, SourcifyChina offers customization options to fit unique operational requirements, including adjustments in span length, lifting height, and control systems.

Q5: What safety features are included in your Ceiling Cranes?

A5: Our cranes include advanced safety features such as overload protection, emergency stop functions, and fail-safe braking systems to ensure maximum operator safety.

Q6: What is the lead time for manufacturing and delivery?

A6: The typical lead time is 4-6 weeks from order confirmation, depending on customization and order volume. Expedited services are available upon request.

Q7: Do you provide installation and after-sales support?

A7: Yes, SourcifyChina offers comprehensive installation services and 24/7 after-sales support, including maintenance, spare parts, and technical assistance.

Q8: Are your Ceiling Cranes energy-efficient?

A8: Absolutely. Our cranes are designed with energy-efficient motors and control systems to minimize power consumption and operational costs.

Q9: How can I request a quote or place an order?

A9: You can request a quote or place an order by visiting our website, contacting our sales team via email, or calling our customer service hotline.

Q10: What certifications do your Ceiling Cranes hold?

A10: SourcifyChina’s Ceiling Cranes hold CE, ISO 9001, and other relevant international certifications, ensuring compliance with global safety and quality standards.

This list of FAQs should help you understand the ultimate quality and services provided by SourcifyChina for Ceiling Cranes. If you have further questions, feel free to reach out to their dedicated support team.