Certainly! Here’s a list of Frequently Asked Questions (FAQ) with answers for sourcing a Container Handling Crane from SourcifyChina factory:

—

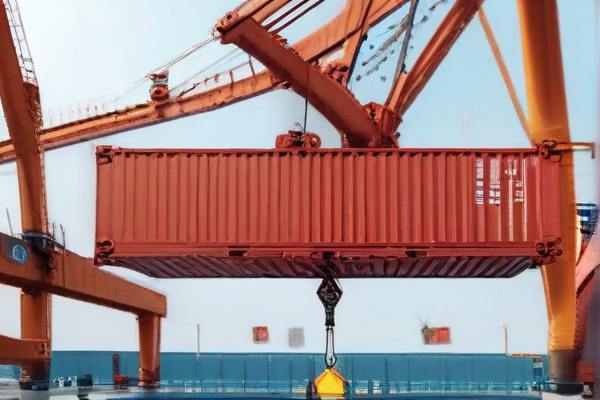

Q1: What types of container handling cranes does SourcifyChina factory offer?

A1: SourcifyChina factory offers a range of container handling cranes including Rail Mounted Gantry Cranes (RMG), Rubber Tyred Gantry Cranes (RTG), and Ship-to-Shore (STS) cranes. These cranes are designed to meet various operational needs of ports and container terminals.

Q2: What is the lead time for manufacturing and delivering a container handling crane?

A2: The lead time for manufacturing and delivering a container handling crane usually ranges from 6 to 12 months, depending on the crane type, customization requirements, and current production capacity.

Q3: Does SourcifyChina factory provide customization options for cranes?

A3: Yes, SourcifyChina factory offers extensive customization options. These may include load capacity, span, lifting height, and additional features like energy-saving systems, remote control, and anti-sway technology.

Q4: What are the quality assurance measures taken by SourcifyChina factory?

A4: SourcifyChina factory adheres to stringent quality assurance protocols, including ISO 9001 standards. Cranes undergo rigorous testing and inspection procedures, ensuring compliance with international safety and quality norms.

Q5: Can SourcifyChina factory assist with installation and maintenance?

A5: Absolutely. SourcifyChina factory provides comprehensive services including installation, commissioning, and training for operator and maintenance personnel. They also offer ongoing maintenance support and spare parts supply.

Q6: What kind of after-sales support is provided?

A6: After-sales support includes warranty services, technical assistance, and availability of spare parts. SourcifyChina factory also offers remote troubleshooting and on-site service if required.

Q7: What information is required to get a quotation?

A7: To get an accurate quotation, provide details such as crane type, desired specifications (load capacity, lifting height, span), intended application, and any special customization needs. This helps in tailoring the quote to your specific requirements.

Q8: Are there financing options available?

A8: SourcifyChina factory may offer flexible financing options or collaborate with financial institutions to facilitate the purchase. It is advisable to discuss financing during initial consultations.

Q9: How can I visit the SourcifyChina factory?