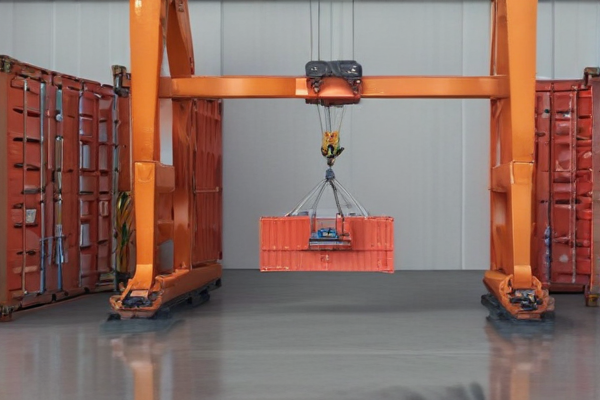

Sure, here’s a concise FAQ for the quality of “Container Lift Crane” work from SourcifyChina factory:

Q1: What certifications does SourcifyChina factory hold?

A1: SourcifyChina factory is ISO 9001 certified, ensuring adherence to international quality management standards.

Q2: How does SourcifyChina ensure the quality of container lift cranes?

A2: We implement rigorous quality control processes, including material inspection, in-process checks, and final product testing to ensure each crane meets our stringent standards.

Q3: What is the typical lead time for manufacturing a container lift crane?

A3: The lead time varies based on specifications and order volume but generally ranges between 8-12 weeks from order confirmation to delivery.

Q4: Can SourcifyChina customize container lift cranes based on specific requirements?

A4: Yes, we offer tailored solutions to meet specific needs, including custom load capacities, crane sizes, and specialized features.

Q5: What materials are used in the construction of your container lift cranes?

A5: Our cranes are constructed using high-grade steel and other durable materials to ensure longevity and reliable performance under heavy loads.

Q6: How does SourcifyChina handle post-purchase support and maintenance?

A6: We provide comprehensive after-sales support, including installation guidance, regular maintenance services, and a warranty to address any issues that may arise.

Q7: Are there any safety features included in your container lift cranes?

A7: Yes, our cranes are equipped with advanced safety features such as overload protection systems, emergency stop functions, and redundant safety mechanisms to ensure operator and load security.

Q8: What is the maximum load capacity of your container lift cranes?

A8: Our standard cranes support up to 40 tons, but custom models can be engineered to accommodate higher capacities as required.

Q9: Can international buyers purchase from SourcifyChina, and do you offer shipping services?

A9: Absolutely, we serve international markets and provide reliable shipping services to ensure your crane arrives safely and promptly.

Q10: What distinguishes SourcifyChina’s container lift cranes from competitors?

A10: Our cranes are distinguished by their superior build quality, customization options, and robust safety features which ensure reliable and efficient container handling operations.