Sure, here is a concise FAQ for manufacturing “Container Yard Crane quality work from SourcifyChina factory.”

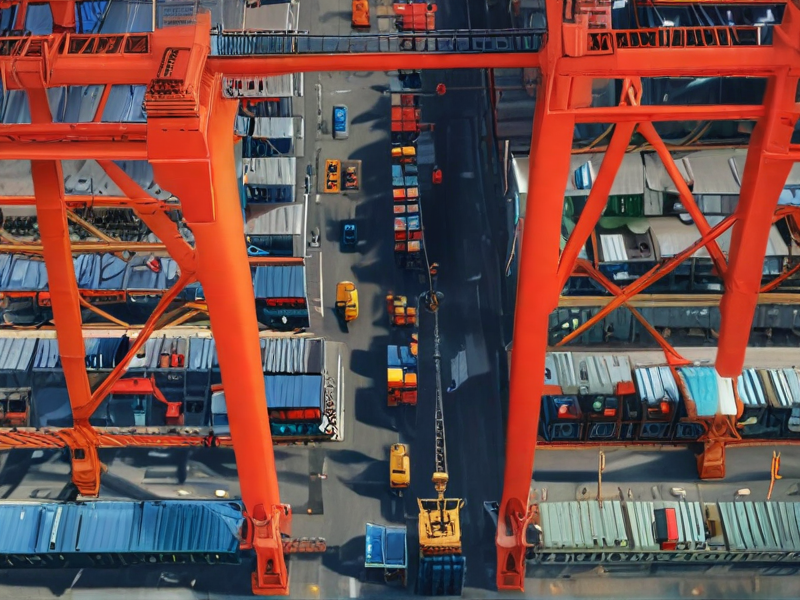

Q1: What types of Container Yard Cranes does SourcifyChina manufacture?

A1: SourcifyChina specializes in a variety of Container Yard Cranes including Rubber Tyred Gantry Cranes (RTGs), Rail Mounted Gantry Cranes (RMGs), and Ship-to-Shore Cranes (STSs), designed to meet diverse operational needs.

Q2: What quality standards do the cranes adhere to?

A2: All our cranes are manufactured in compliance with ISO 9001 quality management standards, ensuring they meet international safety and performance criteria.

Q3: How do you ensure the reliability of your container yard cranes?

A3: We conduct rigorous testing and inspections, including load tests, structural integrity tests, and safety system checks to ensure the cranes meet high standards of reliability.

Q4: What materials are used in the construction of your cranes?

A4: SourcifyChina uses high-strength, corrosion-resistant steel and durable components sourced from reputable suppliers to ensure longevity and minimal maintenance.

Q5: Can you customize cranes based on specific requirements?

A5: Yes, we offer customized solutions tailored to your operational needs, including specific dimensions, load capacities, and additional features like advanced automation systems.

Q6: What is the typical delivery time for a container yard crane?

A6: Delivery time varies depending on the complexity and customization of the crane, but generally ranges from 6 to 10 months after the order is placed.

Q7: Do you provide installation and after-sales support?

A7: Yes, we offer comprehensive installation services and provide ongoing after-sales support, including maintenance, spare parts, and technical assistance.

Q8: What are the safety features included in your cranes?

A8: Our cranes are equipped with advanced safety systems such as anti-collision devices, overload protection, emergency stop functions, and automated control systems to enhance operational safety.

Q9: How energy-efficient are your container yard cranes?

A9: Our cranes are designed with energy-efficient technologies, including regenerative power systems and variable frequency drives that reduce energy consumption and operational costs.

Q10: How can I get a quote for a container yard crane?

A10: You can request a quote by visiting our website, filling out the inquiry form, or contacting our sales team directly. Provide detailed requirements to receive a customized quotation.