Crane accessories enhance the functionality and efficiency of cranes in various industries. From construction to shipping, these tools optimize lifting, loading, and placement operations, ensuring safety and precision.

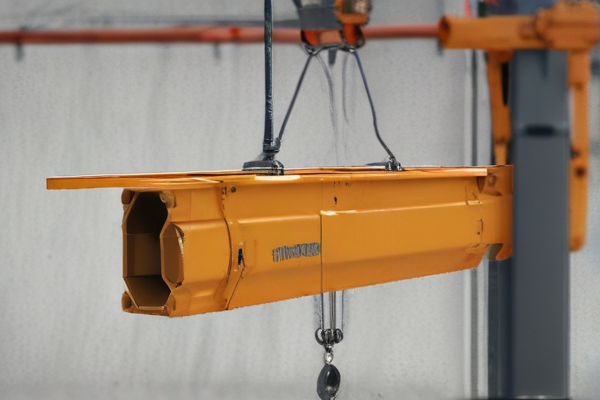

– Lifting Attachments: Clamps, hooks, and lifting beams for versatile hoisting.

– Spreader Bars: Distribute load for balanced lifting.

– Rope and Chains: High-tensile strength materials for secure lifting.

– Load Monitoring Systems: Ensure weight limits are not exceeded.

– Remote Controls: Enable precise, hands-free operations.

– Stabilizers and Outriggers: Increase the stability of cranes during heavy lifts.

– Crane Scales: Provide accurate weight measurement.

– Safety Nets and Guards: Protect operators and bystanders from falling debris.

– Rotational Devices: Allow for 360-degree movement of loads.

– Trolleys and Traversing Systems: Facilitate horizontal movement of loads.

– Magnetic Lifters: For handling metal objects without the need for slings or hooks.

– Load Indicators: Alert operators to potential overload situations.

– Winches: Aid in precise lifting and lowering.

– Boom Extensions: Increase reach for high and distant lifting.

– Man Baskets: Enable safe elevation of personnel.

– Fork Attachments: Convert cranes for forklift-style tasks.

– Cameras and Sensors: Provide visual and spatial feedback for safer operations.

– Hydraulic Grabs: Efficiently handle bulk materials.

– Custom Grippers and Claws: Tailored for specific load types.

– Clamshell Buckets: Ideal for dredging and material handling.

– Jib Cranes: Additional horizontal lifting capabilities.

– Telescopic Booms: Extend and retract for variable reach.

– Counterweights: Ensure balanced and stable operation.

– Lighting Systems: Improve visibility during night operations.

– Weather Protection Covers: Shield components from harsh weather.

– High-Visibility Markers: Enhance safety by ensuring visibility.

– Energy Chains: Protect cables and hoses from damage.

– Swivel Hooks: Enable rotation of loads for precise placement.

– Inspection Platforms: Easy maintenance access.

– Parameter Monitoring Systems: Track operational parameters to maintain safety and efficiency.

These accessories cater to a broad spectrum of needs, making cranes indispensable across various sectors.