Certainly! Here are some FAQs for sourcing crane parts from SourcifyChina factory:

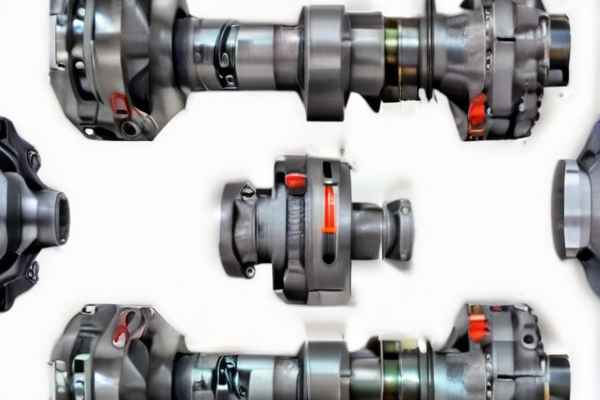

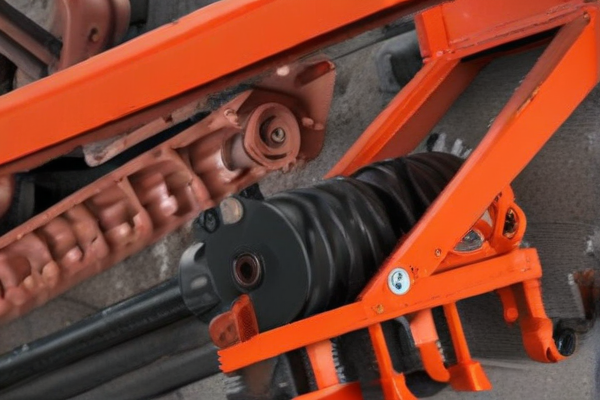

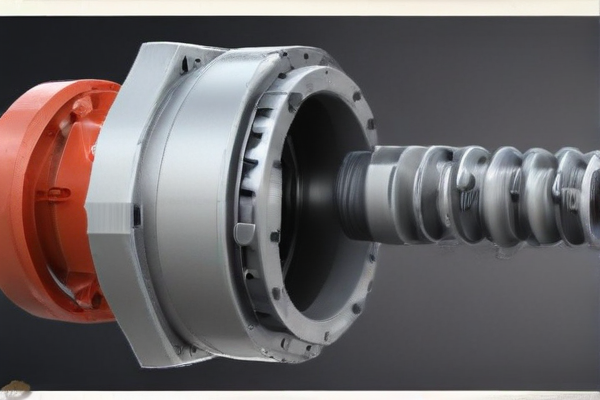

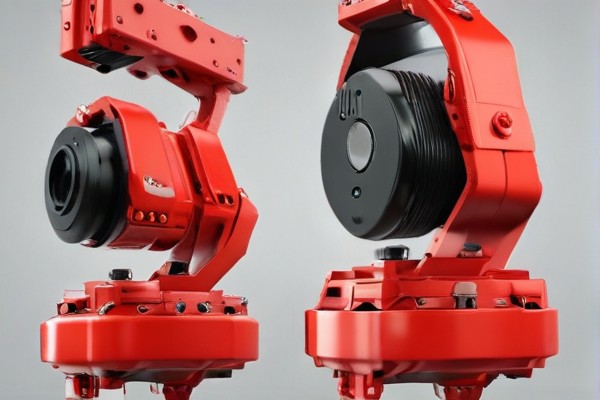

1. What types of crane parts does SourcifyChina supply?

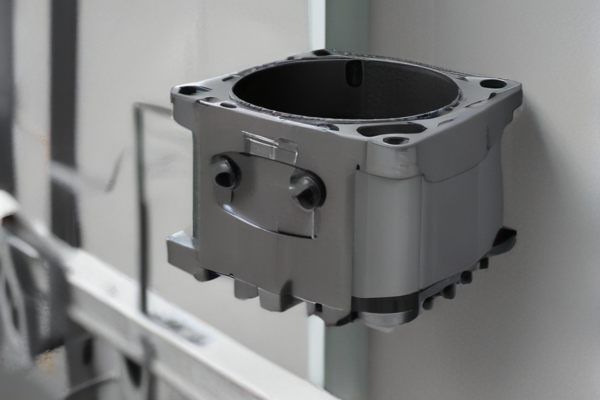

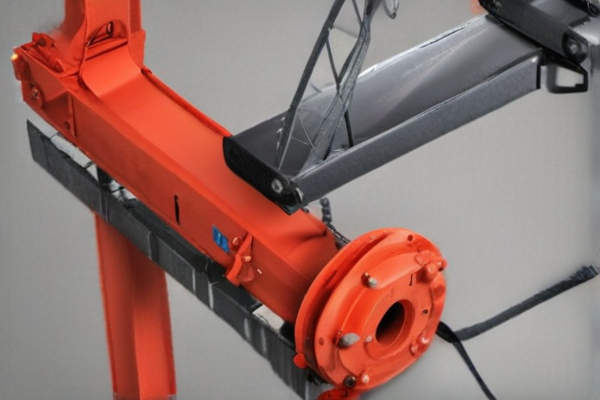

SourcifyChina supplies a wide range of crane parts, including but not limited to hooks, wheels, sheaves, motors, brakes, control systems, and various rigging accessories. We cater to both standard and custom requirements.

2. How can I request a quote for the crane parts?

You can request a quote by visiting our website and filling out the inquiry form, or you can directly contact our sales team via email or phone. Please provide detailed specifications to receive an accurate quote.

3. What is the typical lead time for delivery?

The lead time for delivery varies based on the complexity and quantity of the order. Generally, standard parts take 2-4 weeks, while customized parts may take 6-8 weeks. Exact timelines will be confirmed upon order placement.

4. Do you provide samples for quality evaluation?

Yes, we do provide samples upon request. Sample availability and costs will depend on the specific parts and quantity required.

5. What payment methods are accepted?

We accept multiple payment methods, including T/T (bank transfer), L/C (letter of credit), PayPal, and major credit cards. Specific terms and conditions can be discussed with our sales team.

6. Are there any minimum order quantity (MOQ) requirements?

The MOQ depends on the specific parts you need. Some items may have MOQs due to production and cost efficiency, but we strive to accommodate smaller orders whenever possible.

7. How do you ensure the quality of the crane parts?

Quality is our top priority. SourcifyChina adheres to stringent quality control processes, including material inspection, in-process quality checks, and final product testing. We are ISO certified and comply with international standards.

8. Can you provide custom-made crane parts?

Absolutely! We offer custom manufacturing services to meet your unique requirements. Please provide complete design specifications and drawings, and our engineering team will assist in developing the perfect solution for you.

9. What shipping options are available?

We offer various shipping options including sea freight, air freight, and express delivery services. The choice of shipping method depends on your location, urgency, and budget.

10. What after-sales support do you provide?