Sure, here are the FAQs with answers for sourcing crane railing from SourcifyChina factory:

—

1. What types of crane railings does SourcifyChina factory offer?

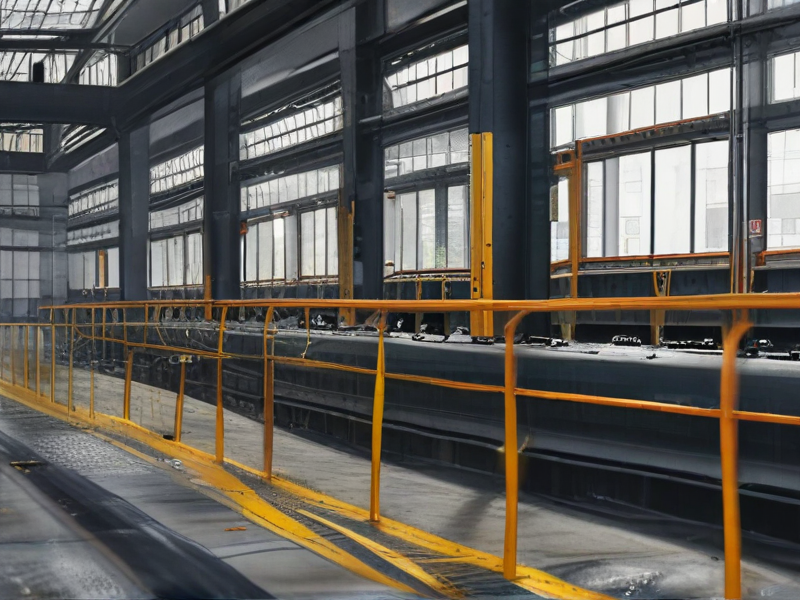

SourcifyChina factory provides a wide range of crane railings, including standard railings, custom-made railings, and heavy-duty railings designed for various industrial applications. They cater to specific requirements such as load capacity, material type, and dimensions.

—

2. Can SourcifyChina factory customize crane railings according to specific requirements?

Yes, SourcifyChina factory specializes in custom manufacturing. They can tailor crane railings to meet precise specifications, including size, shape, material, and load-bearing capacity. Clients can provide detailed drawings or specifications for a bespoke solution.

—

3. What materials are used in the construction of crane railings at SourcifyChina factory?

Crane railings from SourcifyChina factory are typically made from high-quality steel, such as carbon steel or stainless steel, depending on the application requirements. The factory ensures that the materials used meet international standards for durability and safety.

—

4. How does SourcifyChina ensure the quality of their crane railings?

SourcifyChina factory employs strict quality control measures throughout the production process. This includes sourcing high-grade materials, utilizing advanced manufacturing techniques, and conducting thorough inspections and testing to ensure that each crane railing meets safety and performance standards.

—

5. What is the lead time for ordering crane railings from SourcifyChina factory?

The lead time for crane railings varies depending on the complexity and quantity of the order. Generally, standard railings have a shorter lead time, while custom-made railings may take longer. It is best to contact SourcifyChina directly for an accurate estimate based on your specific requirements.

—

6. Does SourcifyChina provide installation services for crane railings?

While SourcifyChina primarily focuses on manufacturing, they can recommend trusted partners for installation services. They also provide detailed installation guides and support to ensure proper and safe installation of their crane railings.

—

7. How can I get a quote for crane railings from SourcifyChina factory?

To get a quote, you can contact SourcifyChina directly through their website or customer service email. Provide detailed information about your requirements, including dimensions, material preferences, load capacity, and any custom features needed. SourcifyChina will respond with a comprehensive quote.

—

8. What are the payment terms for purchasing from SourcifyChina factory?

SourcifyChina factory typically offers flexible payment terms, which may include options such as bank transfer, letter of credit, or other secure payment methods. It’s advisable to discuss and agree on payment terms during the ordering process.

—