FAQ for Sourcing Crane Rollers from SourcifyChina Factory

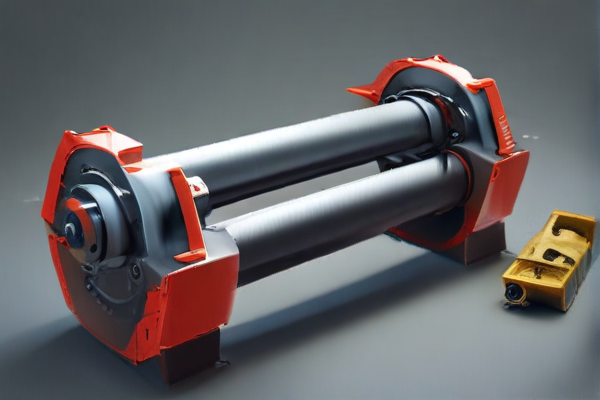

Q: What types of crane rollers does SourcifyChina factory offer?

A: SourcifyChina offers a variety of crane rollers including single flange, double flange, V-groove, flat, and customized rollers to meet different industrial needs.

Q: What materials are used in the manufacturing of crane rollers?

A: The factory primarily uses high-grade steel, alloy steel, and polyurethane. Each material is chosen based on durability, load capacity, and specific application requirements.

Q: Can SourcifyChina factory produce customized crane rollers?

A: Yes, SourcifyChina offers customization services. Customers can specify dimensions, materials, and additional features to meet their specific requirements.

Q: What is the lead time for orders?

A: The standard lead time is 30-45 days depending on the order size and complexity. For customized orders, lead time might vary.

Q: What is the minimum order quantity (MOQ)?

A: The MOQ for crane rollers typically starts at 50 units. However, this can vary based on the type and customization of the rollers.

Q: What quality control measures are in place?

A: SourcifyChina implements strict quality control measures, including material inspection, dimensional checks, load testing, and surface finishing inspections to ensure high-quality products.

Q: Do you provide samples before placing a bulk order?

A: Yes, sample units can be provided for evaluation before confirming a bulk order. There may be additional charges for samples which are often deducted from the bulk order cost.

Q: How does SourcifyChina handle shipping and logistics?

A: SourcifyChina manages shipping and logistics through reliable freight partners. They offer both FOB and CIF terms, ensuring safe and timely delivery.

Q: What payment methods are accepted?

A: Payment methods include T/T (Telegraphic Transfer), L/C (Letter of Credit), and PayPal. Flexible payment terms can be discussed for large orders.

Q: Is there after-sales support available?

A: Yes, SourcifyChina provides comprehensive after-sales support, including technical assistance, warranty services, and replacement of defective parts.

Q: How can I place an order?

A: Orders can be placed directly through their website, by email, or via their sales representatives. Detailed specifications and requirements should be provided to facilitate accurate quotations.