Here’s a list of frequently asked questions (FAQs) about double girder EOT cranes that cover essential information for users and potential buyers:

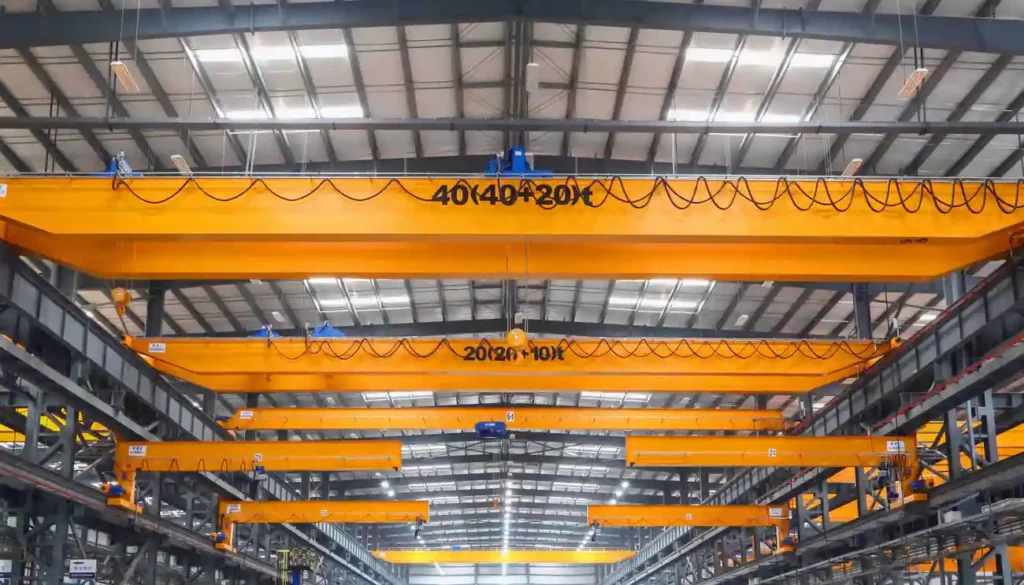

1. What is a Double Girder EOT Crane?

A double girder EOT (Electric Overhead Traveling) crane consists of two bridge beams set atop the runway, which are used to support the trolley and hoist. This design allows for higher load capacities and larger spans compared to single girder cranes.

2. What are the advantages of using a Double Girder EOT Crane?

- Higher Load Capacity: Can handle more weight, suitable for heavy industrial applications.

- Larger Spans: Able to cover wider spans, making them ideal for large factory settings.

- Better Hook Height: Offers higher vertical lift as the hoist can be placed between or on top of the girders.

- Durability: Typically more robust and built for continuous, rigorous use.

3. Are Double Girder Cranes customizable?

Yes, double girder cranes can be customized based on specific requirements such as lifting capacity, span, speed, duty cycle, and additional features like anti-collision devices, variable frequency drives, and remote controls.

4. What industries benefit most from Double Girder EOT Cranes?

Industries that commonly use these cranes include manufacturing, metal mills, shipbuilding, power generation, automotive, and aerospace. They are ideal for applications that involve heavy lifting and precise movement.

5. How do I choose the right Double Girder EOT Crane for my needs?

Consider the following factors:

- Capacity: Maximum weight the crane needs to lift.

- Span: Width of the area the crane needs to cover.

- Lift Height: Distance the crane must lift materials vertically.

- Duty Cycle: Frequency and intensity of crane use.

- Environment: Conditions under which the crane will operate (e.g., outdoor, hazardous, etc.).

6. What safety features are available for Double Girder EOT Cranes?

Safety features can include overload protection, emergency stop systems, anti-collision technology, and warning alarms. Regular maintenance and inspections are crucial for ensuring safety.

7. What is the typical maintenance schedule for a Double Girder EOT Crane?

Maintenance schedules vary based on the crane’s usage and environment but generally include daily checks, monthly inspections, and annual servicing. Key focus areas are the structural integrity of beams, the functionality of the hoist and trolley, and the condition of electrical components.

8. How much does a Double Girder EOT Crane cost?

The cost can vary widely based on capacity, span, customizations, and manufacturer. It’s essential to get quotes from multiple vendors to understand the price range and included features.

9. Can Double Girder EOT Cranes operate outdoors?

Yes, with the appropriate modifications for weather protection, such as weatherproofing electrical components and using materials suitable for outdoor environments, these cranes can operate outdoors.

10. Where can I buy a Double Girder EOT Crane?

Double girder cranes can be purchased from specialized industrial crane manufacturers. It’s recommended to consult with industry experts and check vendor credentials and reviews before making a purchase.

These FAQs should help clarify common queries about double girder EOT cranes and assist in making informed decisions regarding their purchase and use.