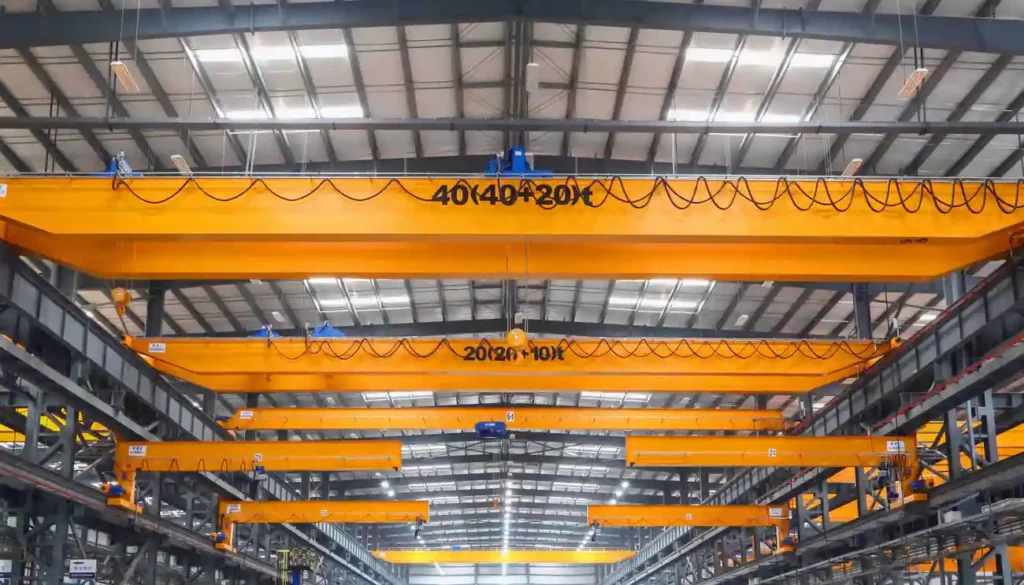

Manufacturing Facilities: Double girder overhead cranes are crucial in manufacturing plants for handling heavy machinery, large components, and assembly lines. They facilitate the movement of materials and products efficiently, enhancing productivity and safety.

Warehousing and Logistics: In warehouses and logistics centers, these cranes are used for loading and unloading heavy goods, optimizing space utilization, and streamlining the logistics process.

Construction Sites: These cranes are essential for construction projects, aiding in the lifting and positioning of construction materials, steel beams, and prefabricated structures, ensuring timely project completion.

Steel Mills and Foundries: In steel mills and foundries, double girder overhead cranes handle hot metal, steel coils, and large castings, providing the strength and durability needed to operate in harsh environments.

Shipbuilding: The shipbuilding industry relies on these cranes for assembling ship components, transporting heavy sections, and outfitting ships, making them indispensable for efficient and safe shipyard operations.

Power Plants: In power generation facilities, double girder overhead cranes are used for the maintenance of turbines, generators, and other heavy equipment, ensuring operational reliability and safety.

Automotive Industry: These cranes support the automotive sector by handling car bodies, engines, and other heavy parts, facilitating efficient assembly line operations and maintenance tasks.

Paper and Pulp Industry: In the paper and pulp industry, they handle large rolls of paper, equipment, and raw materials, streamlining production processes and reducing downtime.

Mining Operations: Double girder overhead cranes are used in mining operations for lifting heavy machinery, ores, and other materials, contributing to the efficiency and safety of mining activities.

Aerospace Industry: These cranes assist in the manufacturing and maintenance of aircraft by handling large and delicate components, ensuring precision and safety in aerospace operations.

Double girder overhead cranes are versatile and robust, making them suitable for a wide range of industrial applications where heavy lifting, precision, and safety are paramount.