EOT Crane Parts FAQ

Here are some frequently asked questions (FAQs) about Electric Overhead Traveling (EOT) crane parts, providing insights into their functionality, maintenance, and more:

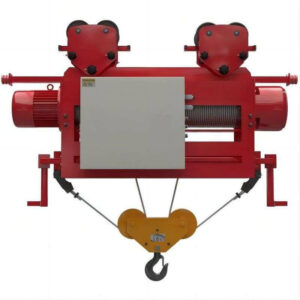

What are the main components of an EOT crane?

An EOT crane primarily consists of a bridge, hoist, trolley, end trucks, runway, electrical systems, and safety devices. Each part plays a crucial role in the crane’s operation and safety.

How often should EOT crane parts be inspected?

Regular inspections are recommended at least once a year for light-duty cranes and as often as monthly for cranes in heavy-duty or continuous operation. Key components like wire ropes, brakes, and hooks may require more frequent checks.

What are common maintenance tasks for EOT crane parts?

Maintenance tasks include lubricating moving parts, checking and adjusting brakes, inspecting wire ropes for wear and damage, and ensuring electrical components are functioning properly.

What safety devices are included in EOT cranes?

Safety features typically include overload protectors, limit switches, emergency stop buttons, and anti-collision devices to ensure safe operations and prevent accidents.

How do I choose the right EOT crane for my needs?

Consider factors such as the maximum load capacity, the height of lift, the span of the crane, duty cycle, operating environment, and specific operational requirements like speed and precision.

Can EOT crane parts be customized?

Yes, parts like the hoist, trolley, and control systems can be customized based on specific operational needs, such as lifting speed, control method (remote or cabin), and environmental conditions.

What should I do if a component of the EOT crane fails?

Cease crane operations immediately to prevent further damage or accidents. Consult a professional service technician who specializes in crane repair to diagnose and resolve the issue.

What is the typical lifespan of an EOT crane?

The lifespan of an EOT crane can vary widely based on usage, maintenance, and environmental conditions but typically ranges from 20 to 30 years with proper care and regular maintenance.

How do environmental conditions affect EOT crane parts?

Environmental factors such as humidity, temperature extremes, and corrosive atmospheres can accelerate wear and necessitate more frequent maintenance or specific materials and coatings to enhance durability.

Are there regulatory standards for EOT crane operation and maintenance?

Yes, EOT cranes must comply with standards set by organizations like OSHA (Occupational Safety and Health Administration), ANSI (American National Standards Institute), and other regional regulatory bodies depending on the location.

These FAQs aim to provide a comprehensive understanding of EOT crane parts, their maintenance, and operational best practices to ensure safety and efficiency in industrial applications.