Sure, here are some frequently asked questions (FAQ) with answers related to manufacturing Gantry Cranes at SourcifyChina factory:

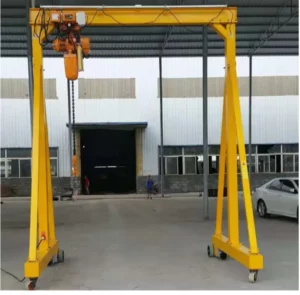

Q: What types of Gantry Cranes does SourcifyChina manufacture?

A: SourcifyChina manufactures a variety of Gantry Cranes including single girder, double girder, and portable gantry cranes, all customizable to meet specific project requirements.

Q: How do you ensure the quality of your Gantry Cranes?

A: We implement strict quality control procedures, including material inspection, welding quality checks, load testing, and compliance with ISO standards, ensuring reliable and durable products.

Q: What materials are used in your Gantry Cranes?

A: Our gantry cranes are typically constructed using high-quality steel, ensuring strength and durability. We also use corrosion-resistant materials and coatings to extend the lifespan of the cranes.

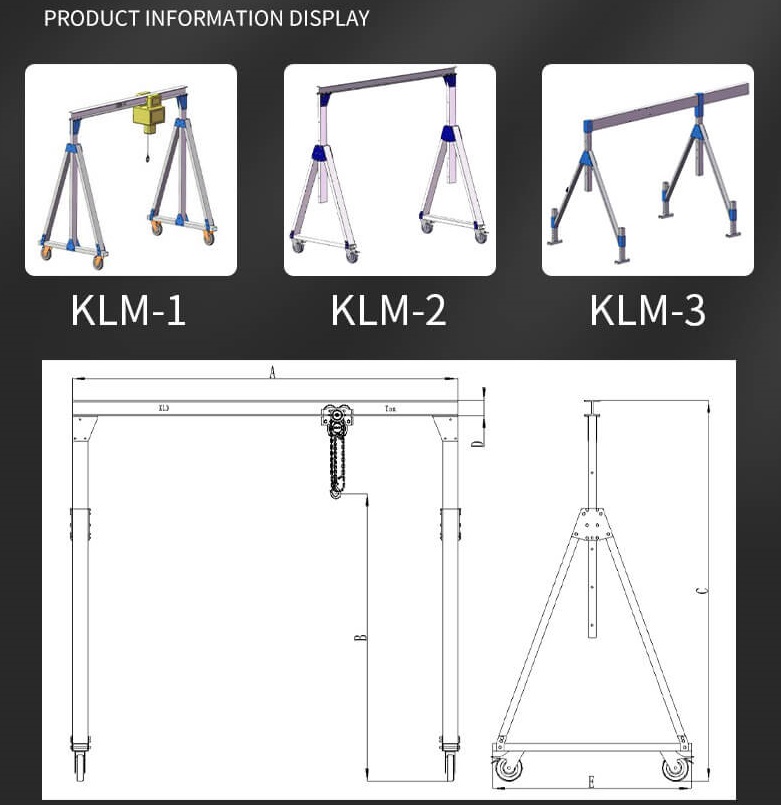

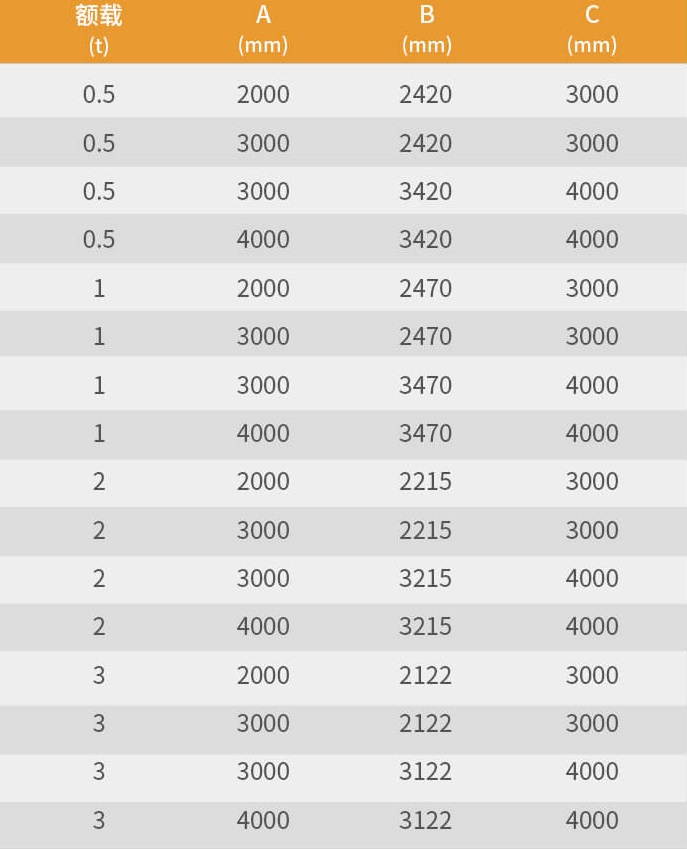

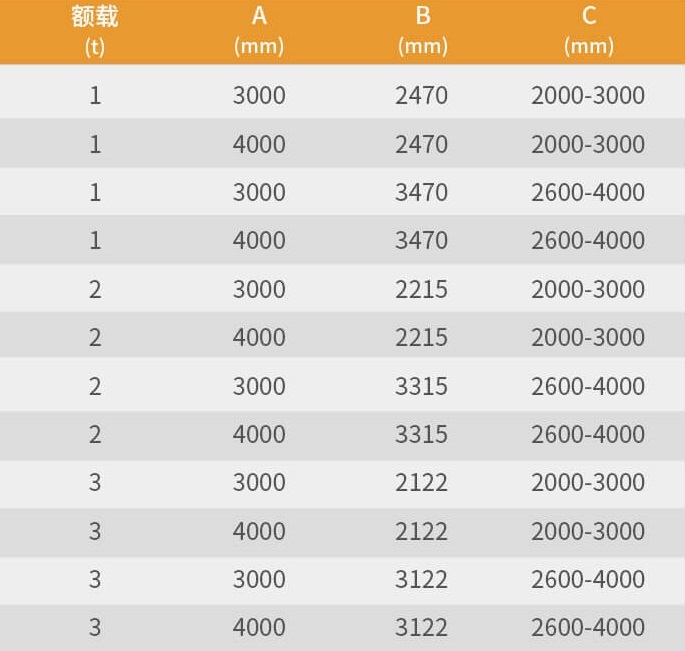

Q: Can SourcifyChina customize Gantry Cranes to specific requirements?

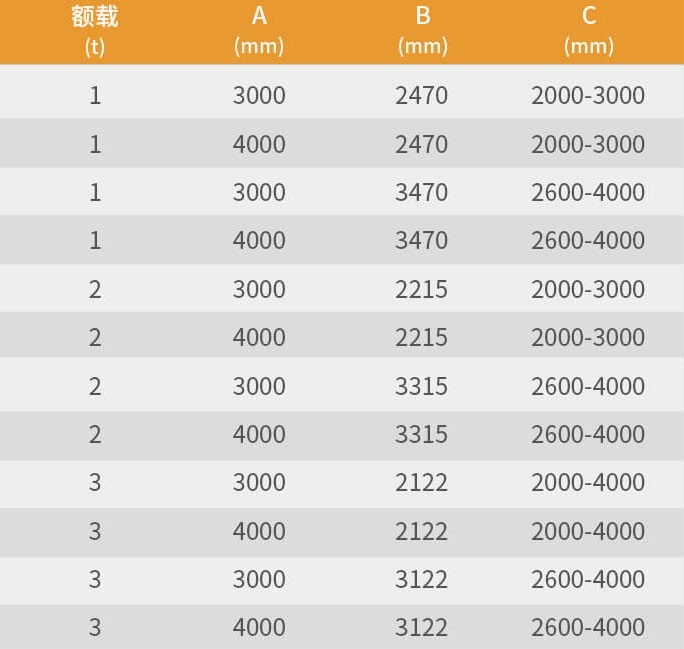

A: Yes, we offer customization options to meet unique project needs. Clients can specify dimensions, load capacities, and additional features like motorized travel, controls, and safety devices.

Q: How long does it take to manufacture a Gantry Crane?

A: The lead time for manufacturing depends on the complexity and customization of the crane. Generally, it ranges from 4 to 8 weeks from order confirmation.

Q: What kind of after-sales support do you provide?

A: We offer comprehensive after-sales support including installation guidance, operational training, maintenance services, and a warranty to ensure optimal performance of our gantry cranes.

Q: Are your Gantry Cranes compliant with international safety standards?

A: Yes, all our gantry cranes comply with international safety and quality standards such as ISO, CE, and OSHA regulations, ensuring safe and reliable operation.

Q: Do you provide onsite installation services?

A: We can arrange for professional installation services upon request, depending on the location and specific requirements of the project.

Q: How can I place an order for a Gantry Crane from SourcifyChina?

A: You can contact us via our website, email, or phone. Our sales team will assist you with product selection, customization options, and the complete ordering process.