An In-Depth Analysis of Manufacturing Expenses for Gantry Crane Price

Analyzing the manufacturing expenses associated with gantry cranes necessitates examining several critical cost components.

Materials: This constitutes a significant portion of the overall expense. Key materials include high-strength steel for the frame and gantries, motors, electrical components, wheels, and often rubber or polyurethane for tire treads. Fluctuations in raw material costs directly impact the final price, with high-grade steel and advanced composite materials generally commanding higher prices due to their durability and performance metrics.

Labor: Skilled labor is essential for fabricating and assembling gantry cranes. Welders, machinists, and electricians contribute to the primary cost of labor. Additionally, the complexity of design can extend production times, thus increasing labor costs. Labor costs also vary depending on geographic location and the prevailing wage rates in the manufacturing region.

Machinery and Tooling: Manufacturing gantry cranes involves specialized machinery such as CNC machines, welding equipment, and hydraulic presses. The initial investment in such equipment, along with maintenance and depreciation costs, forms a crucial part of the manufacturing expenses.

Design and Engineering: Customization requirements for various industrial applications necessitate significant investment in R&D, engineering design, and compliance testing. Efficient design can reduce material wastage and improve manufacturability, thereby affecting overall costs.

Overhead: This includes utilities, factory overheads, administrative expenses, and quality control measures. Rigorous testing to ensure safety and adherence to industry standards adds to the overhead costs.

Logistics: Transportation of the finished gantry crane and its components is another substantial expense. Given their size and weight, special handling and transportation arrangements are often necessary, contributing to higher logistics costs.

Regulatory Compliance: Meeting national and international standards for safety, environmental impact, and operational efficacy necessitates additional expenses in terms of certifications, inspections, and compliance procedures.

In conclusion, the price of manufacturing a gantry crane is a cumulative result of material costs, labor, machinery investments, design and engineering efforts, overheads, logistics, and regulatory compliance. Understanding these factors provides a comprehensive view of the financial considerations involved in gantry crane production.

Understanding the Components that Contribute to the Price of Gantry Crane Price

The price of a gantry crane is influenced by several key components and factors that collectively determine the final cost. Here are the primary elements:

1. Material Costs: The type and quality of materials used in constructing the crane significantly impact its price. High-strength steel and corrosion-resistant materials are more expensive but enhance durability and performance.

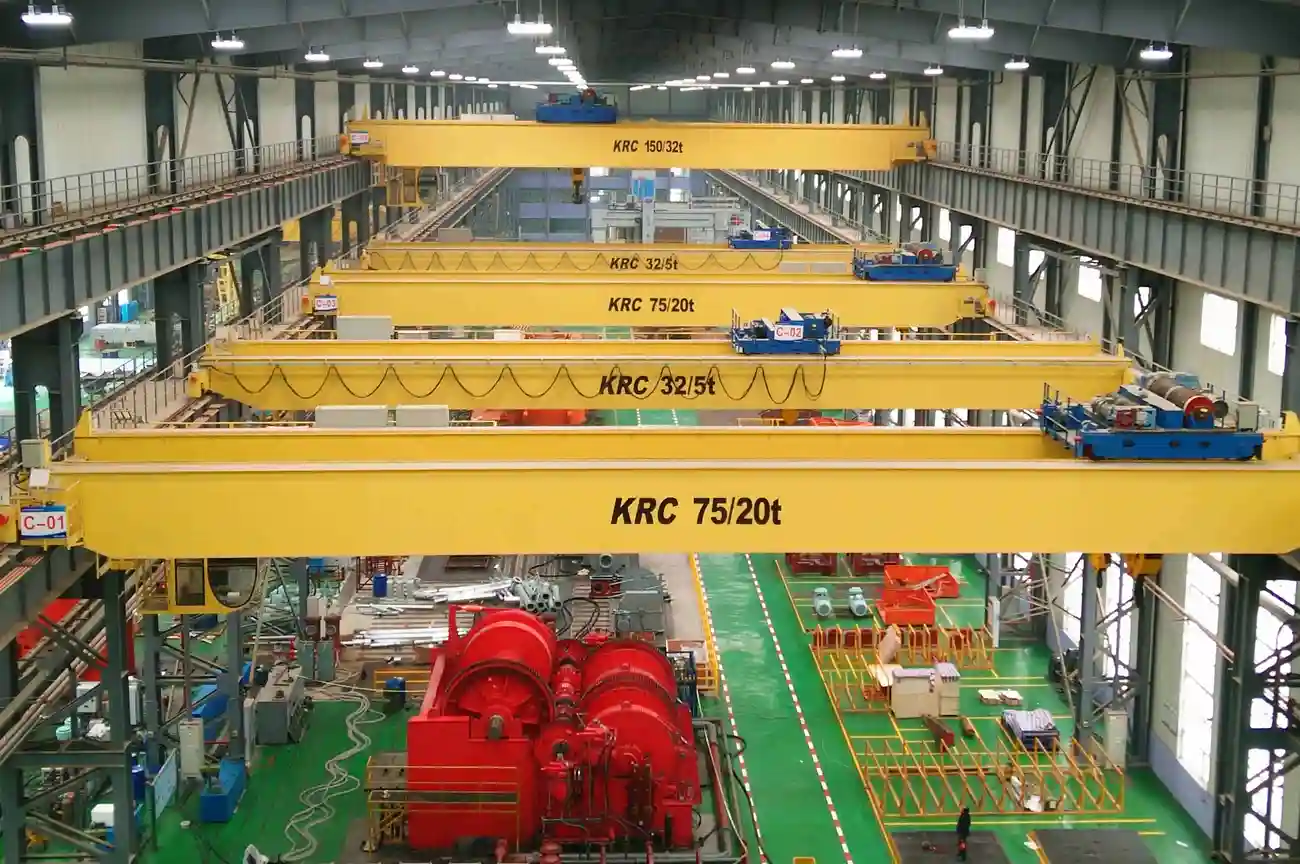

2. Load Capacity: The crane’s lifting capacity is a major determinant. Higher capacity cranes require more robust construction, stronger materials, and more sophisticated engineering, thereby increasing the cost.

3. Span and Height: The crane’s dimensions, including its span (width) and lifting height, affect the price. Larger spans and greater heights require additional material and more complex design considerations, leading to higher costs.

4. Type of Gantry Crane:

– Single Girder vs. Double Girder: Double girder cranes, which have two beams, tend to be more expensive than single girder cranes due to their enhanced load capacity and greater structural complexity.

– Full Gantries vs. Semi Gantries: Full gantry cranes, which have legs on both sides running on the ground, are typically more expensive than semi gantries that have one leg on the ground and one side attached to a building.

5. Customization and Features: Any additional customizations like motorized trolleys, specialized hoists, remote controls, and automation features will add to the cost. Bespoke designs tailored to specific applications also tend to be pricier.

6. Brand and Manufacturer Reputation: Well-established manufacturers known for their reliable and durable products generally command higher prices.

7. Installation and Commissioning: The cost of transporting, installing, and commissioning the crane on-site is another factor. Complex installations in remote or challenging environments can drive up the overall price.

8. After-Sales Service: Warranties, maintenance packages, and availability of spare parts can also influence the initial purchase price, reflecting the potential total cost of ownership.

By understanding these components, buyers can make informed decisions that balance cost with functionality and durability to meet their specific operational needs.

Comparing the Wholesale and Retail Prices of Gantry Crane Price in China

When examining the price differentials between wholesale and retail markets for gantry cranes in China, several factors come into play, including scale, customization, intermediary costs, and market demands.

Wholesale Prices:

Wholesale prices for gantry cranes in China are generally lower due to bulk purchasing and direct transactions with manufacturers or large suppliers. Wholesalers often benefit from economies of scale, reduced per-unit costs, and minimal intermediary expenses. The average price for a standard gantry crane ranges from $10,000 to $50,000, depending on capacity, materials, and technology. Heavy-duty cranes and bespoke models, complete with advanced features, can range between $100,000 and $500,000. Businesses purchasing in large quantities can negotiate further discounts, benefiting overall project budgets.

Retail Prices:

Retail prices, in contrast, are higher due to added costs such as dealer markups, marketing expenses, shipping, after-sales services, and warranties. Retailers cater to smaller buyers who often require additional services like installation, maintenance, and technical support, justifying the added expenses. Consequently, the retail price for typical gantry cranes ranges from $15,000 to $70,000. For high-capacity or customized models, prices can soar to $120,000 or more.

Price Drivers:

Several factors influence these price bands:

1. Customization: Tailored solutions for specific client needs add to costs.

2. Technology: Advanced safety systems, automation, and better materials increase both wholesale and retail values.

3. After-Sales Service: Comprehensive support packages add value and cost for retail buyers.

4. Brand Reputation: Established manufacturers with strong reputations charge premium prices, reflected more prominently in retail markets.

In conclusion, while wholesale purchasers of gantry cranes in China benefit from lower prices due to bulk buys and fewer intermediaries, retail buyers face higher costs because of added services and smaller order sizes.

Understanding Shipping and Logistics for Gantry Crane Price from China

Shipping and Logistics for Gantry Crane Price from China

Understanding the logistics and shipping costs involved in importing a gantry crane from China is crucial for budgeting and smooth procurement. Here’s a breakdown of key aspects:

1. Port of Origin and Destination:

Shipping costs vary significantly based on the departing Chinese port (e.g., Shanghai, Shenzhen) and the destination. Proximity to major shipping routes can reduce costs.

2. Shipping Modes:

– *Sea Freight:* Most cost-effective for large, heavy items like gantry cranes. Options include Full Container Load (FCL) and Less than Container Load (LCL).

– *Air Freight:* Faster but much more expensive, suitable for urgent or smaller components.

3. Incoterms:

Understand the International Commercial Terms (Incoterms) used in your contract:

– *EXW (Ex Works):* Buyer takes responsibility from the seller’s location.

– *FOB (Free On Board):* Seller covers costs until the crane is on board the ship.

– *CIF (Cost, Insurance, and Freight):* Seller covers costs until the destination port.

4. Tariffs and Duties:

Import duties vary by country and product classification. Check your country’s Harmonized System (HS) code for gantry cranes to estimate tariffs.

5. Insurance:

Cargo insurance is vital to cover potential damage or loss during transit, typically around 1-3% of the crane’s value.

6. Documentation:

Essential documents include the Bill of Lading, Commercial Invoice, Packing List, and Certificate of Origin. Delays in paperwork can result in additional costs or delays.

7. Local Logistics:

Consider inland transportation from the destination port to your installation site. Beware of potential costs such as offloading, storage, and local freight charges.

8. Customs Clearance:

Efficient customs clearance requires accurate documentation and possibly broker services. Ensure compliance with local regulations.

Proper planning and understanding of these factors can help manage costs and avoid delays in procuring a gantry crane from China.

Potential Tariffs or Import Taxes on Gantry Crane Price Purchased from China

When purchasing gantry cranes from China, it’s essential to consider potential tariffs and import taxes that could significantly impact the final price. These charges vary depending on various factors, including the country of import, trade relations, and specific product classifications.

1. Harmonized System (HS) Code: Gantry cranes are typically categorized under specific HS codes, which are used globally to classify traded products. For instance, they might fall under HS code 8426.19, which covers mobile lifting frames on tires and straddle carriers. Knowing the correct HS code is crucial as it determines the duty rate.

2. Import Duties: The import duty rate for gantry cranes varies by country. For example, the U.S. International Trade Commission (USITC) provides a Schedule of Tariff Rates, where duties can range based on the crane’s specifics. Similarly, the European Union has its Common External Tariff (CET) dictating import duties.

3. Anti-Dumping Duties: Some regions may impose anti-dumping duties on cranes from China if they determine that Chinese manufacturers are selling them at unfairly low prices. These duties can be substantial and could make the total cost considerably higher.

4. Value-Added Tax (VAT): Many countries impose VAT on imported goods, including gantry cranes. This tax is usually a percentage of the crane’s value, added to the cost post-import duties.

5. Tariff Exclusions or Reductions: In some situations, countries may offer tariff exclusions or reductions, particularly if the cranes are for specific industrial projects or have certain technological features.

6. Trade Agreements: Bilateral or multilateral trade agreements like USMCA (for North American countries) or various others could affect tariffs. It’s vital to check whether any such agreements could benefit your import scenario.

Given the complexity and variability of these duties and taxes, it’s advisable to consult with a customs broker or trade consultant to get accurate calculations tailored to your importing country and specific product regulations.

Impact of Market Demand and Competitive Environment on Gantry Crane Price

The price of gantry cranes is influenced significantly by market demand and the competitive environment. When market demand for gantry cranes is high, driven by robust construction activities, infrastructure projects, and industrial expansions, manufacturers often experience increased order volumes, leading to higher prices. The heightened demand can result in longer lead times and potential supply shortages, which further push prices upward. Conversely, during periods of low demand, perhaps due to economic downturns or reduced capital expenditures, prices may decrease as suppliers compete more aggressively to win limited contracts.

The competitive environment also plays a critical role. In a highly competitive market with numerous manufacturers and suppliers, companies are inclined to offer competitive pricing to capture market share. This competition can lead to reduced prices and better deals for buyers, as suppliers strive to outdo each other. On the other hand, if a few dominant players control the market, prices may be higher and more stable, as these companies have greater pricing power and less incentive to engage in price wars.

Technological advancements and innovation also impact gantry crane prices. Companies investing in cutting-edge technology and advanced materials may offer higher-priced, high-performance cranes, which cater to niche segments willing to pay a premium for superior products. However, these advancements often push older models’ prices down, as they become less attractive.

Global trade dynamics, such as tariffs, import restrictions, and currency exchange rates, further complicate pricing. Import duties and tariffs increase costs for imported cranes, affecting their market price. Lastly, operational costs, including labor, raw materials, and regulatory compliance, inevitably affect the final pricing structure.

In summary, the interplay of market demand and the competitive landscape, alongside technological progress and global trade factors, collectively shapes the pricing strategies for gantry cranes.

FAQ about Gantry Crane Price

Here are some top FAQs about gantry crane prices:

What factors influence the price of a gantry crane? The price of a gantry crane is influenced by several factors including its capacity (tonnage), span length, lifting height, duty cycle, and any specialized features or customizations required for specific applications.

How much does a standard gantry crane cost? A standard gantry crane can vary significantly in price, ranging from as low as $5,000 for simple, light-duty models to over $100,000 for heavy-duty, high-capacity models. Prices can vary based on the specifications and configurations.

Are there different prices for different types of gantry cranes? Yes, the price of a gantry crane can vary depending on its type. Adjustable gantry cranes, fixed gantry cranes, and portable gantry cranes each have different price points, reflecting their capabilities and structural complexities.

Can the operating environment affect the cost of a gantry crane? Absolutely. Gantry cranes designed for harsh environments, such as those with extreme temperatures or corrosive conditions, may require additional engineering and materials, which can increase the cost.

How does the material of construction affect the price? The choice of materials, whether steel or aluminum, impacts the price. Aluminum gantry cranes are typically more expensive than steel ones but offer the advantage of being lighter and more resistant to corrosion.

What are the costs associated with installing a gantry crane? Installation costs can vary widely depending on the complexity of the installation, the location, and the need for specialized labor. These costs are in addition to the purchase price of the crane itself.

Do prices include shipping and handling? In many cases, prices do not include shipping and handling charges. These costs can be significant, especially for large and heavy units, and will vary based on the distance and logistics involved.

Is there a difference in price between custom and off-the-shelf gantry cranes? Custom gantry cranes are generally more expensive than off-the-shelf models because they are designed and built to meet specific operational requirements.

How can I get the best price on a gantry crane? To get the best price, it’s advisable to obtain quotes from several suppliers and compare their offerings. Consider not only the purchase price but also the quality, warranty, and ongoing support costs.

Are there financing options available for purchasing a gantry crane? Many manufacturers and dealers offer financing options to help manage the large upfront cost of a gantry crane. It’s worth inquiring about these options to spread out the investment over time.

These FAQs can help guide potential buyers in understanding the pricing landscape of gantry cranes and what factors may affect their purchasing decisions.