Sure, here’s a list of FAQ with answers for manufacturing “Hot Metal Crane quality work from SourcifyChina factory”:

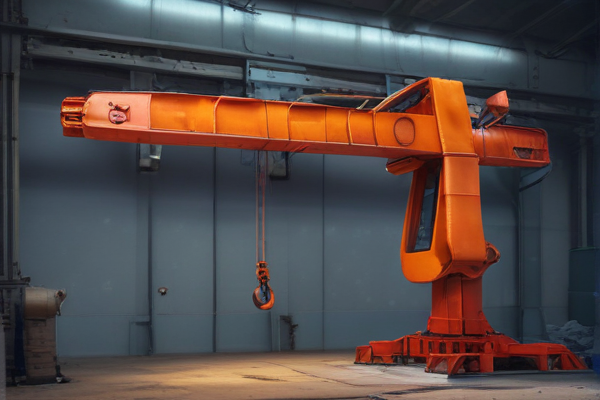

1. What is Hot Metal Crane?

Hot Metal Cranes are specialized overhead cranes designed to handle molten metal safely and efficiently in foundries and steel mills.

2. Why should I choose SourcifyChina factory for Hot Metal Cranes?

SourcifyChina factory is renowned for its high-quality manufacturing standards, robust safety features, and customizable designs tailored to meet specific industrial requirements.

3. What safety standards do your Hot Metal Cranes adhere to?

Our Hot Metal Cranes comply with internationally recognized safety standards such as ISO 9001 and OSHA regulations, ensuring optimal safety during operations.

4. Can I customize the Hot Metal Crane to meet my specific needs?

Yes, SourcifyChina factory offers full customization options to adapt to your particular operational requirements, including load capacity, spans, and lifting speeds.

5. What are the typical lead times for manufacturing and delivery?

Lead times may vary depending on the complexity and customization of the crane, but typically it ranges from 8 to 12 weeks from order confirmation to delivery.

6. What materials are used in manufacturing your Hot Metal Cranes?

Our cranes are constructed using high-strength alloy steel to withstand extreme temperatures and conditions associated with handling molten metal.

7. Do you provide installation services?

Yes, we offer comprehensive installation services carried out by experienced professionals to ensure efficient and safe operational setup.

8. How do you ensure the quality of your Hot Metal Cranes?

We conduct rigorous quality control inspections at each stage of the manufacturing process, including final load-testing and operational verification.

9. What maintenance services do you offer?

We provide ongoing maintenance support, including preventive maintenance programs, spare parts supply, and technical assistance to ensure the longevity and reliability of your crane.

10. How can I get a quotation or place an order?

To request a quotation or place an order, you can contact us via email or phone, providing your specifications and requirements. Our sales team will respond promptly with detailed information.

11. Do you offer any warranties on your Hot Metal Cranes?

Yes, we offer a comprehensive warranty covering defects in materials and workmanship for a specified period, ensuring peace of mind and reliable performance.