Industrial cranes are essential tools in various sectors, facilitating the movement, lifting, and transportation of heavy loads with precision and efficiency. They are crucial for improving productivity, safety, and operational efficiency.

– Construction: Lifting and placing heavy materials like steel beams, concrete blocks, and other building components.

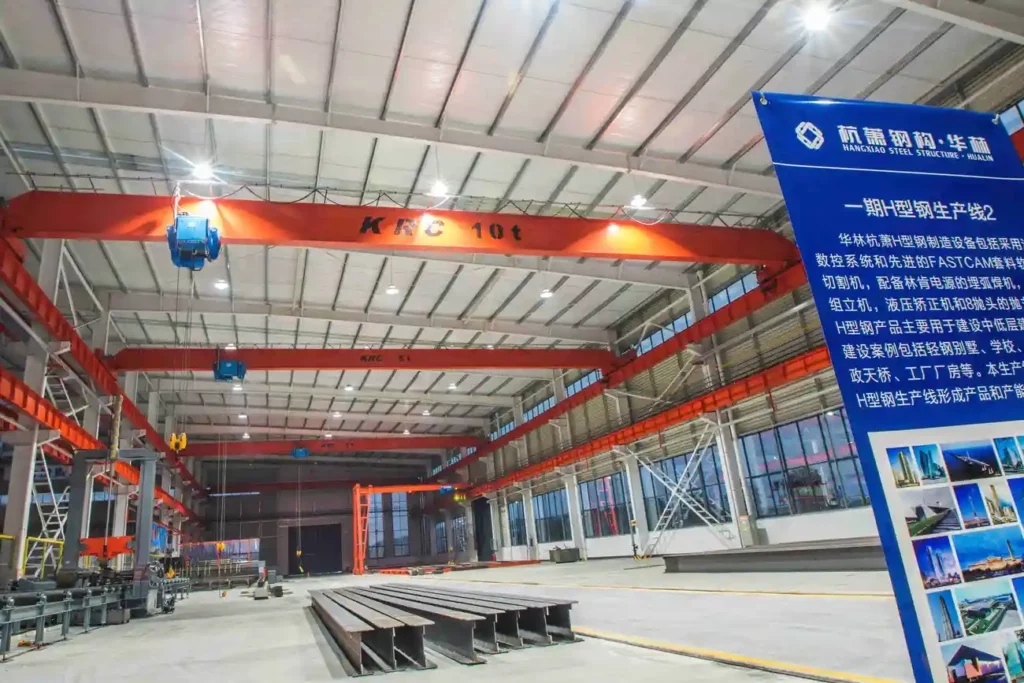

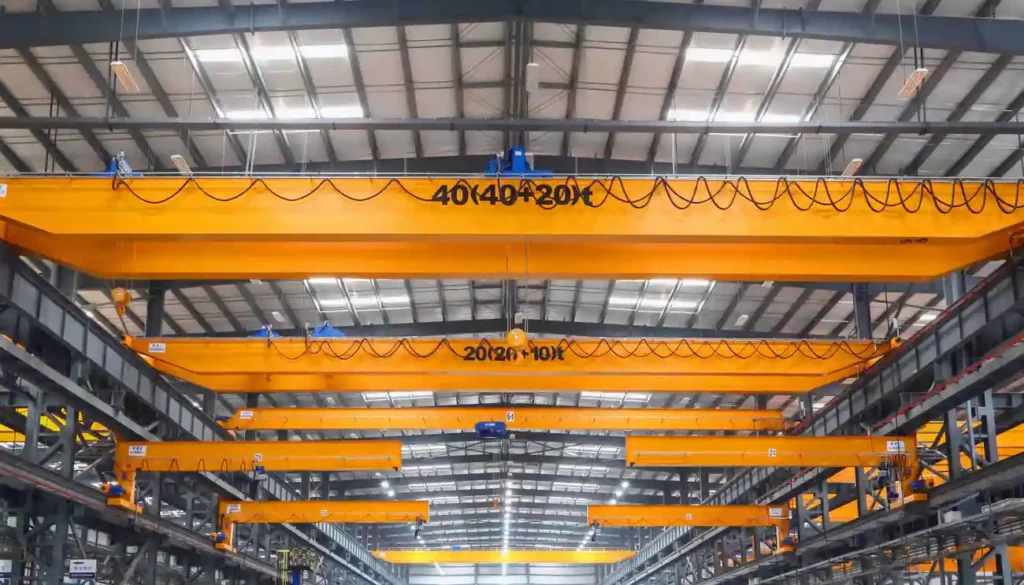

– Manufacturing: Moving large machinery, assembling heavy parts, and relocating materials within factories.

– Shipping Ports: Loading and unloading containers from ships to docks and vice versa.

– Warehouses: Handling large volumes of goods and materials, optimizing storage space.

– Mining: Transporting extracted ore, equipment, and other heavy materials within mining sites.

– Automotive: Moving engines, vehicle bodies, and large automotive parts during assembly.

– Energy: Assembling and maintaining wind turbines, pipelines, and other infrastructure in the energy sector.

– Aerospace: Handling large aircraft components, including assembling and testing aircraft parts.

– Railway: Lifting and maintaining train cars, tracks, and other railway infrastructure.

– Event Setup: Installing stages, lighting systems, and large structures for concerts, fairs, and exhibitions.

– Rescue Operations: Assisting in disaster relief by lifting debris and other heavy materials.

– Utilities: Maintaining and installing heavy infrastructure such as electricity poles and transformers.

– Waste Management: Handling large waste containers, recycling materials, and managing landfill operations.

– Steel Industry: Handling steel coils, slabs, and other heavy steel products throughout the production process.

– Chemical Plants: Moving heavy chemical containers and processing equipment.

– Heavy Equipment Repair: Lifting and transporting heavy machinery for maintenance and repairs.

– Forestry: Transporting large logs and other forestry products.

– Bridge Building: Assembling and placing bridge sections and components.

– HVAC Systems: Installing and maintaining large heating, ventilation, and air conditioning units.

These versatile machines significantly enhance productivity and ensure the smooth operation of various industrial activities, making them indispensable in modern industry.