Frequently Asked Questions (FAQ) for Sourcing Intermodal Container Crane from SourcifyChina Factory

#### 1. What types of intermodal container cranes does SourcifyChina factory offer?

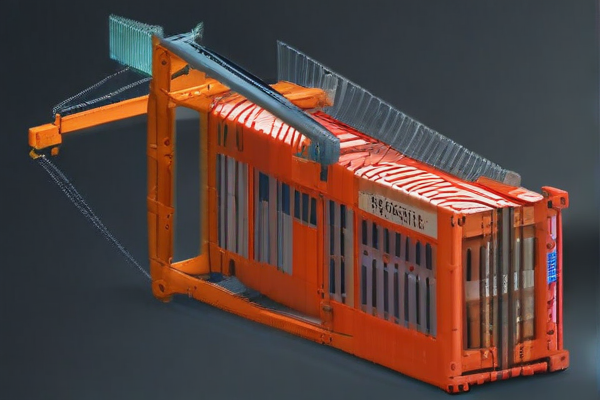

SourcifyChina factory provides a range of intermodal container cranes including Rail-Mounted Gantry Cranes (RMG), Rubber-Tyre Gantry Cranes (RTG), and Ship-to-Shore Cranes (STS), tailored to meet various operational needs.

#### 2. How do I request a quote for an intermodal container crane?

To request a quote, you can visit our website and fill out the contact form, send an email to our sales team at [email protected], or call us directly. Please include details about your requirements, such as crane type, capacity, and any specific features.

#### 3. What is the lead time for manufacturing and delivery?

The lead time varies based on the complexity and quantity of the order. On average, manufacturing and delivery take approximately 8-12 weeks. Our team will provide a more accurate timeline upon receiving your specific requirements.

#### 4. Do you provide installation and after-sales support?

Yes, SourcifyChina offers comprehensive installation services and after-sales support, including maintenance and troubleshooting. Our team of experts ensures that your crane is installed correctly and operates efficiently.

#### 5. What quality standards do your cranes adhere to?

Our intermodal container cranes are manufactured in compliance with international standards such as ISO, FEM, and DIN. We ensure high-quality workmanship, durable materials, and rigorous testing to meet all safety and performance criteria.

#### 6. Can you customize cranes according to specific requirements?

Absolutely, we specialize in customizing cranes to meet the unique needs of our clients. Whether you need specific dimensions, load capacities, or other custom features, we can design and manufacture cranes tailored to your specifications.

#### 7. What payment methods are accepted?

We accept various payment methods including bank transfers (T/T), Letters of Credit (L/C), and other secure methods. Terms and conditions will be discussed during the quotation and contract process.

#### 8. How can I ensure the crane’s quality before shipment?

We encourage clients to visit our factory for a pre-shipment inspection. Alternatively, we can provide detailed inspection reports, videos, and third-party certification upon request to guarantee the quality before shipment.

#### 9. Do you offer training for operating the crane?