Sure, here’s a list of frequently asked questions (FAQs) regarding sourcing a Jib Crane from SourcifyChina factory:

Q: What types of jib cranes does SourcifyChina offer?

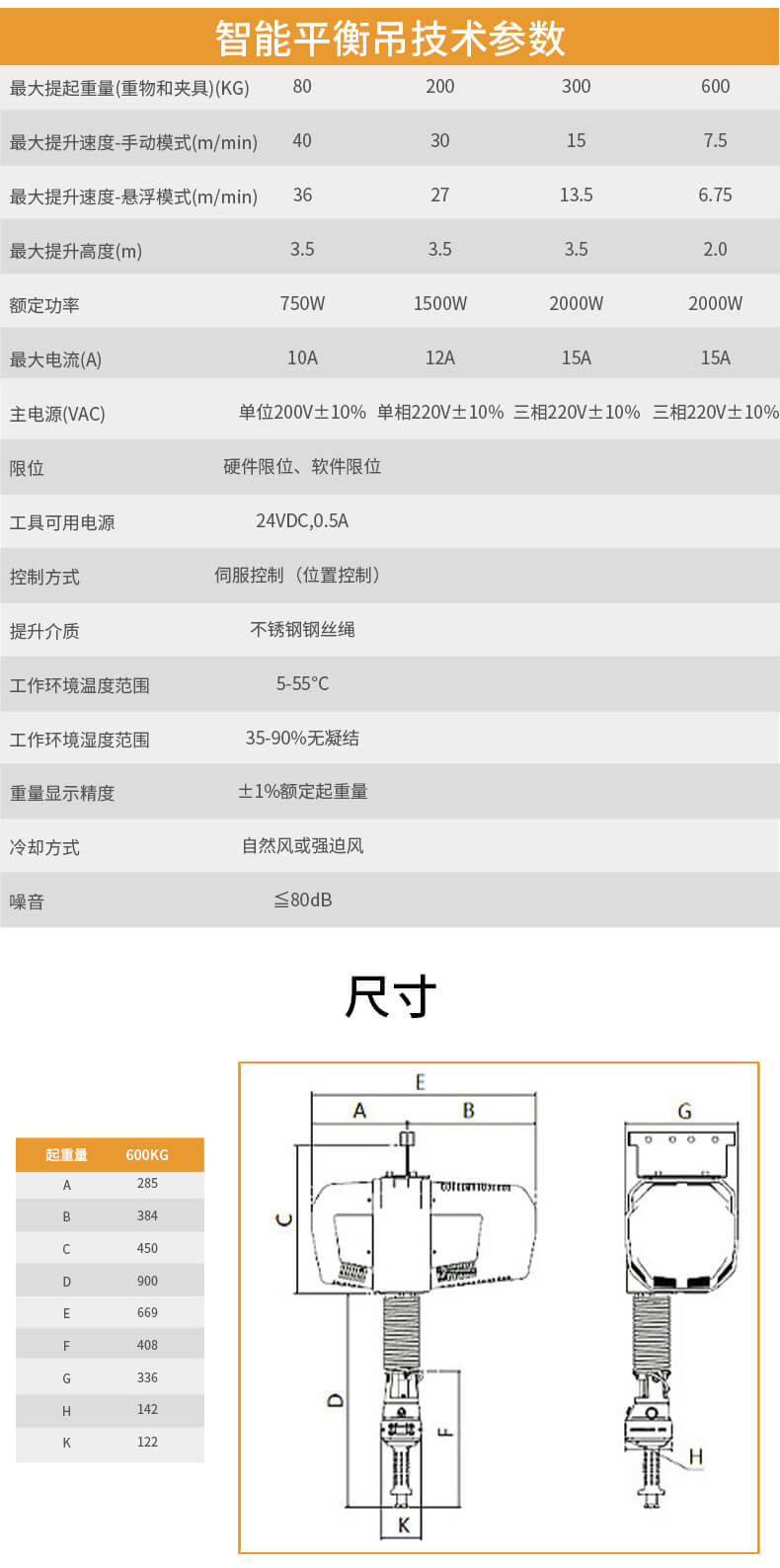

A: SourcifyChina offers a variety of jib cranes, including wall-mounted, free-standing, and column-mounted models. Each type has different specifications to meet various industrial needs.

Q: How do I place an order?

A: To place an order, contact SourcifyChina’s sales team through their official website or email. Provide details about the type and specifications of the jib crane you need, and they’ll guide you through the ordering process.

Q: What is the lead time for delivery?

A: The lead time varies depending on the model and quantity ordered. On average, expect a lead time of 4-6 weeks for standard models. Custom orders might take longer.

Q: Do you offer customization?

A: Yes, SourcifyChina offers customization options to meet specific requirements. You can customize the crane’s load capacity, span, and height. Discuss your needs with their technical team for precise customization.

Q: What are the payment terms?

A: Payment terms typically include a deposit of 30% upon order confirmation, with the remaining balance due before shipping. Detailed payment terms can be negotiated directly with the sales team.

Q: Are there warranties and after-sales support?

A: Yes, SourcifyChina provides a standard warranty for their jib cranes, usually covering 1-2 years. They also offer after-sales support, including maintenance services and spare parts.

Q: Can I request a sample or onsite inspection before placing a bulk order?

A: While samples for jib cranes might not be feasible, you can request an onsite inspection. SourcifyChina welcomes clients to visit their factory for a firsthand look at their manufacturing process and quality standards.

Q: What certifications do SourcifyChina’s jib cranes have?

A: SourcifyChina’s jib cranes comply with international standards and may have certifications like ISO, CE, or others depending on the specific model. Check with the sales team for the exact certifications.

Q: How is shipping handled?

A: SourcifyChina can arrange shipping to your location. They offer various shipping methods, including sea, air, and land freight. Shipping costs and times will depend on your location and the shipping method chosen.

Q: What information do I need to provide for a quote?