Sure, here are some FAQs related to the manufacturing of Ladle Crane quality work from SourcifyChina factory:

Q: What are Ladle Cranes used for?

A: Ladle Cranes are primarily used in steel plants to transfer molten metal. They are crucial for handling ladles of liquid metal safely and efficiently.

Q: How does SourcifyChina ensure the quality of Ladle Cranes?

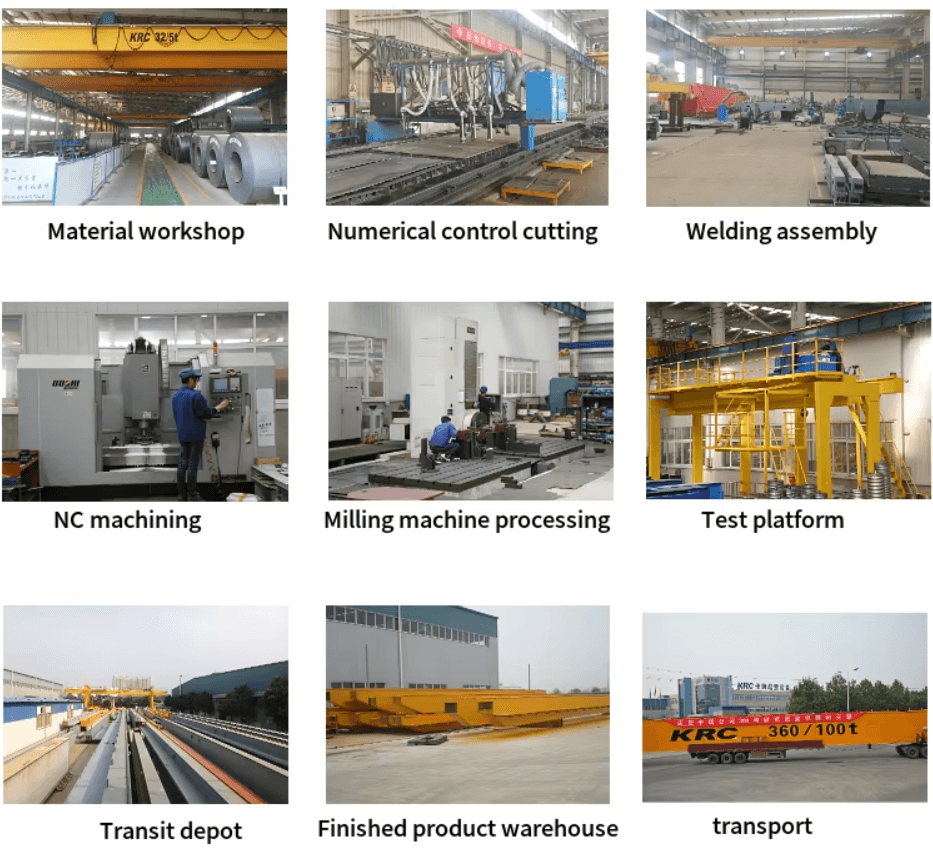

A: SourcifyChina follows stringent quality control processes. Each crane undergoes rigorous testing and inspection to ensure it meets industry standards and client specifications. The factory uses high-grade materials and advanced technologies.

Q: What materials are used in manufacturing Ladle Cranes at SourcifyChina?

A: SourcifyChina uses high-strength steel and other durable materials to ensure the crane can withstand extreme conditions and heavy loads.

Q: Can SourcifyChina customize Ladle Cranes according to specific requirements?

A: Yes, SourcifyChina offers customization options to tailor the design, capacity, and features of Ladle Cranes according to the specific needs of the client.

Q: What safety features are integrated into Ladle Cranes from SourcifyChina?

A: SourcifyChina’s Ladle Cranes come with multiple safety features, including overload protection, emergency stop functions, and specialized heat-resistant designs to ensure safe operation in high-temperature environments.

Q: How long does it typically take to manufacture a Ladle Crane at SourcifyChina?

A: The manufacturing timeline can vary based on the complexity and customization requirements. Generally, it takes a few months for complete production, including quality checks and testing.

Q: Does SourcifyChina provide after-sales support and maintenance for Ladle Cranes?

A: Yes, SourcifyChina offers comprehensive after-sales support, including maintenance, repair services, spare parts, and technical assistance to ensure the long-term functionality of the cranes.

Q: Are there certifications available for Ladle Cranes from SourcifyChina?

A: SourcifyChina’s Ladle Cranes adhere to international standards. The factory provides all relevant certifications and documentation to verify the quality and authenticity of its products.

Q: How can I place an order for a Ladle Crane at SourcifyChina?

A: You can place an order by contacting SourcifyChina’s sales team via email or phone. Detailed project requirements and specifications will be discussed to provide a tailored solution.