Sure, here’s a concise FAQ for manufacturing “Machine Shop Crane quality work from SourcifyChina factory”:

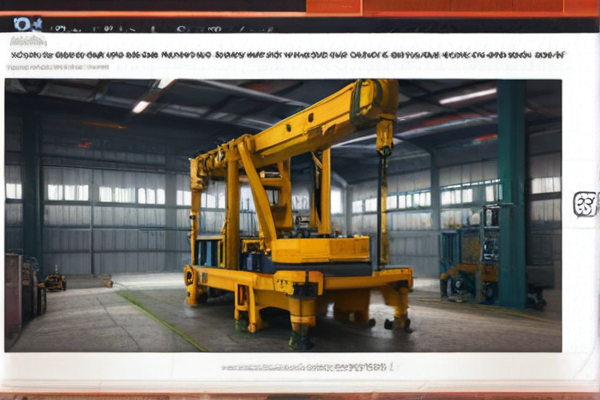

Q1: What types of cranes does SourcifyChina manufacture for machine shops?

A1: SourcifyChina specializes in a variety of cranes including overhead cranes, gantry cranes, jib cranes, and workstation cranes, designed to meet diverse industrial needs.

Q2: How do you ensure the quality of your cranes?

A2: Quality is ensured through stringent quality control processes, including material inspection, performance testing, and compliance with international standards like ISO 9001.

Q3: Are customizations available for specific requirements?

A3: Yes, we offer customization to meet specific needs such as load capacity, span, lifting height, and additional features like automation or remote control systems.

Q4: What materials are used in the manufacturing of these cranes?

A4: We use high-grade steel and components from reputable suppliers to ensure durability, strength, and longevity of our cranes.

Q5: What is the typical lead time for manufacturing a crane?

A5: The lead time depends on the crane type and customization level but generally ranges from 4 to 8 weeks.

Q6: How do you handle shipping and logistics?

A6: We provide complete shipping solutions including packaging, documentation, and coordination with reliable logistics partners to ensure timely delivery.

Q7: Are there warranties available for your cranes?

A7: Yes, SourcifyChina offers warranties typically ranging from 12 to 24 months, covering manufacturing defects and providing after-sales support.

Q8: Do you provide installation services?

A8: We offer installation guidance and services through trained technicians to ensure proper and safe crane setup.

Q9: How do you support after-sales service and maintenance?

A9: Our after-sales support includes technical assistance, spare parts supply, and maintenance services to ensure optimal performance of your cranes.

Q10: What certification do your cranes have?

A10: Our cranes comply with industry standards and certifications, such as CE and ISO, ensuring quality and safety.

Feel free to reach out for more specific information or queries related to your project needs.