FAQ for Sourcing Metallurgical Crane from SourcifyChina Factory

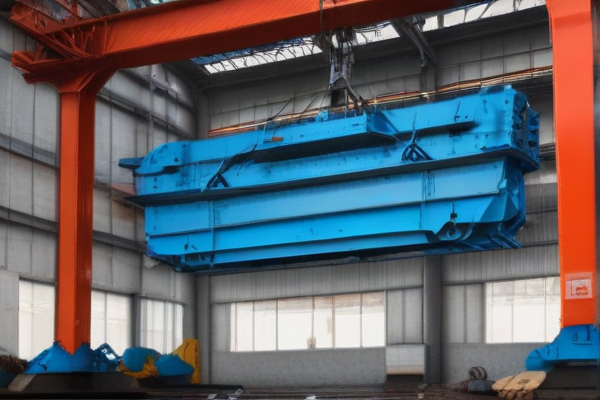

Q1: What types of metallurgical cranes does SourcifyChina offer?

A: SourcifyChina provides a wide range of metallurgical cranes, including ladle cranes, billet handling cranes, and scrap handling cranes. These cranes are designed for various high-temperature and heavy-duty applications in metallurgical industries.

Q2: Are the metallurgical cranes from SourcifyChina compliant with international standards?

A: Yes, the metallurgical cranes from SourcifyChina are manufactured in compliance with international standards such as ISO, FEM, and ASME to ensure high quality and safety.

Q3: Can SourcifyChina customize a crane to specific requirements?

A: Absolutely, SourcifyChina specializes in customizing cranes to meet clients’ specific needs. Whether it’s lifting capacity, span, or special coating requirements, they provide tailored solutions.

Q4: What are the lead times for delivery?

A: Lead times typically depend on the crane’s specifications and customization level. Generally, standard models have shorter delivery times, while customized cranes may take longer. It’s advisable to discuss lead times during the initial consultation.

Q5: What kind of after-sales support does SourcifyChina offer?

A: SourcifyChina offers comprehensive after-sales support, including installation, commissioning, maintenance services, and spare parts supply. They also provide technical support through phone or email.

Q6: How can we ensure the quality of the crane before purchase?

A: SourcifyChina provides detailed product specifications, quality assurance certifications, and test reports. Additionally, they welcome factory inspections or third-party audits by clients.

Q7: What are the payment terms offered by SourcifyChina?

A: Payment terms are usually negotiable but typically involve a percentage of the total cost paid upfront, with the balance due upon completion or delivery. Common methods include T/T (Telegraphic Transfer) or L/C (Letter of Credit).

Q8: Are there any warranties provided?

A: Yes, SourcifyChina offers warranties on their metallurgical cranes, which cover parts and labor for a specified period, ensuring peace of mind for their clients.

Q9: How do I place an order with SourcifyChina?

A: To place an order, you can contact their sales team via email or phone. Providing detailed requirements will help expedite the process, and a sales representative will guide you through the procurement steps.

Q10: Can SourcifyChina assist with installation and training?