Sure, here are some frequently asked questions (FAQ) about sourcing a Port Container Crane from SourcifyChina factory, with each question highlighted for clarity:

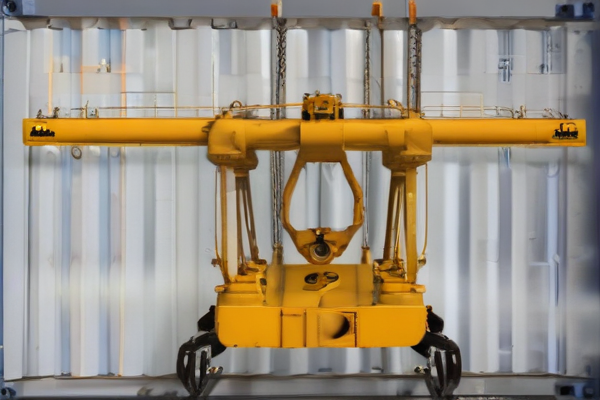

Q: What types of port container cranes does SourcifyChina offer?

A: SourcifyChina offers a range of port container cranes including ship-to-shore (STS) cranes, rail-mounted gantry (RMG) cranes, rubber-tired gantry (RTG) cranes, and automated stacking cranes (ASC).

Q: How can I request a quote from SourcifyChina?

A: To request a quote, you can visit SourcifyChina’s official website and fill out the inquiry form, or contact their sales department via email or phone. Provide detailed requirements to receive an accurate estimate.

Q: What is the lead time for manufacturing and delivery?

A: The lead time varies based on the complexity and specifications of the crane. Generally, it takes between 4 to 6 months for manufacturing and an additional few weeks for delivery, depending on the destination.

Q: Can SourcifyChina customize cranes based on specific requirements?

A: Yes, SourcifyChina offers customization options to meet specific operational and dimensional requirements. It’s crucial to discuss your needs in detail with their technical team during the initial consultation.

Q: What kind of warranty and after-sales service does SourcifyChina provide?

A: SourcifyChina provides a standard warranty period, usually ranging from 12 to 24 months. They also offer after-sales services such as maintenance, spare parts supply, and technical support.

Q: Are there any quality certifications for SourcifyChina port container cranes?

A: Yes, SourcifyChina cranes are manufactured following international standards and carry various certifications such as ISO, CE, and others as required.

Q: What payment methods are accepted?

A: SourcifyChina accepts various payment methods including wire transfer (T/T), Letter of Credit (L/C), and sometimes escrow services, subject to agreement.

Q: How can I be assured of the crane’s quality?

A: SourcifyChina allows for factory visits and third-party inspections. They adhere to rigorous quality control processes and provide all necessary certifications and test reports.

Q: Does SourcifyChina assist with installation and training?

A: Yes, SourcifyChina provides on-site installation and commissioning services. They also offer training programs for your operational staff to ensure safe and efficient crane operation.