In the context of construction, gantry cranes are pivotal for their versatility and robustness, capable of handling a range of tasks from lifting heavy building materials to installing large structures. Here’s a detailed overview of the types of gantry cranes specifically suitable for construction applications, classified by their key characteristics and uses

A-Frame Gantry Cranes:

Description: Characterized by their A-shaped legs, which provide stability and strength. This design allows for high load capacity and durability, making it ideal for various construction environments.

Common Uses: Useful in building sites for moving large items like steel beams, precast concrete blocks, and heavy machinery.

Wheeled Gantry Cranes:

Description: These cranes are equipped with wheels, providing mobility across the construction site. They can be moved easily, which is particularly advantageous in dynamic construction environments where lifting points frequently change.

Common Uses: Ideal for tasks that require the crane to be relocated regularly, such as moving supplies or equipment across large construction sites.

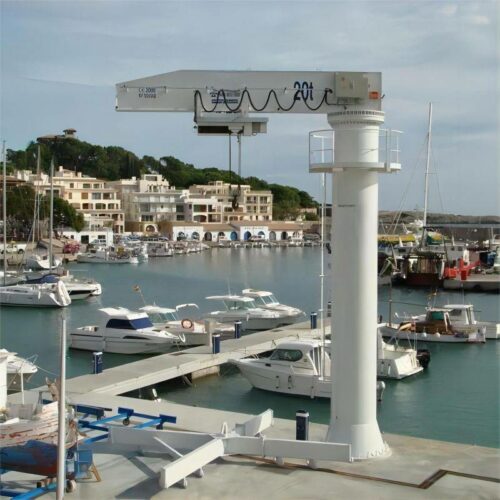

Outdoor Gantry Cranes:

Description: Designed to endure outdoor working conditions, these cranes are built with materials and finishes that resist corrosion and damage from weather elements. They often come with higher power ratings and rugged design.

Common Uses: Used in large-scale construction projects, such as the building of bridges, highways, or high-rise structures.

4 Post Gantry Cranes:

Description: Features four legs for enhanced stability, capable of supporting larger loads than their two-legged counterparts. These cranes are often customizable and can be engineered to meet specific site requirements.

Common Uses: Suitable for heavy-duty lifting tasks, including the installation of large structural components or in sites with uneven ground where extra stability is crucial.

Railroad Gantry Cranes:

Description: Although specifically designed for railroad applications, their robust design and high lifting capacities make them adaptable for large-scale construction, especially in infrastructure projects.

Common Uses: Often used in the construction and maintenance of railway lines or large infrastructure projects that require high precision and heavy lifting capabilities.

Harbor Freight Gantry Cranes:

Description: More economical and less robust than industrial cranes, these are suitable for lighter tasks or smaller construction sites where budget and space are constraints.

Common Uses: Ideal for smaller building projects, home construction, or where the frequency of use does not justify a more substantial investment.

Each type of construction gantry crane offers specific benefits tailored to different aspects of construction work, from heavy lifting and high mobility to budget-friendly options for smaller projects. This variety ensures that there's a gantry crane solution for nearly any type of construction challenge.