Container gantry cranes are specialized pieces of equipment designed for the efficient handling and transfer of shipping containers in ports and intermodal terminals. Here are several key categories of container gantry cranes, differentiated by their design, technology, and operational characteristics.

Each of these categories addresses specific operational needs of container handling facilities, from compact ports to major global hubs, enhancing the efficiency and throughput of cargo movements.

Ship-to-Shore Cranes (STS): These are the large gantry cranes typically seen at container ports. They are used for loading and unloading containers from cargo ships to the dockside. They can vary greatly in size, lift capacity, and outreach capability depending on the size of the port and the ships they service.

Rail Mounted Gantry Cranes (RMG): These cranes move on fixed rails and are commonly used in large container yards for stacking and moving containers between different stacks. They are known for their high efficiency and ability to handle high volumes of container movements.

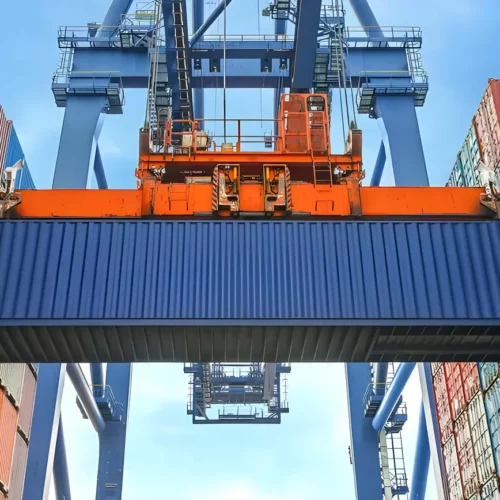

Rubber Tired Gantry Cranes (RTG): Similar in function to RMGs, RTGs run on rubber tires instead of rails, offering greater flexibility in movement and placement. They are ideal for smaller or medium-sized container yards where space constraints require more mobility.

Automated Stacking Cranes (ASC): These are typically used in automated container terminals. ASCs operate without direct human intervention, controlled entirely by computer systems. They offer significant improvements in efficiency and safety, reducing operational costs and increasing throughput.

Mobile Harbor Cranes: While not fixed like traditional gantry cranes, mobile harbor cranes can be used for handling containers and are versatile in managing different types of cargo. They are useful in smaller ports or as a supplementary system in larger ports.

Jumbo and Super-Post Panamax Cranes: These are larger versions of STS cranes designed to service the biggest container ships in the world. They have extended reach and height capabilities, allowing them to manage containers stacked many rows deep on the ship.