Specialty gantry cranes are designed to meet specific industrial requirements and challenges, often tailored to operate under unique conditions or handle special types of loads. These cranes are engineered for precision, safety, and efficiency in environments where standard gantry cranes cannot suffice. Here are several key categories of specialty gantry cranes, each crafted to serve distinct functions within various industries.

Each of these specialty gantry crane categories is developed with particular industrial needs in mind, ensuring that they can perform effectively in specialized applications where general-purpose cranes might not be adequate. Whether it’s handling delicate operations that require precision or operating in adverse environmental conditions, specialty gantry cranes are indispensable tools in the modern industrial landscape.

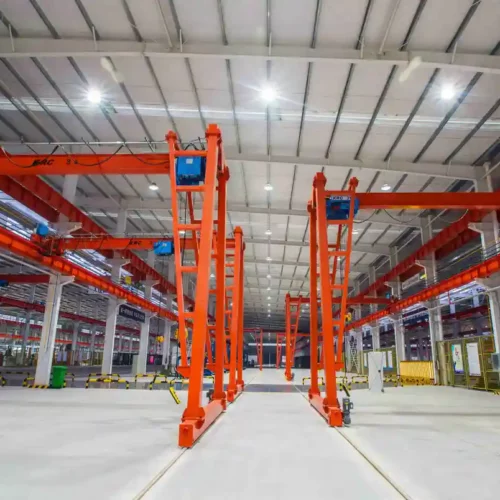

High-Capacity Gantry Cranes: These cranes are built to handle extremely heavy loads, often exceeding several hundred tons. They are commonly used in heavy industries like shipbuilding and large-scale manufacturing, where large components such as ship sections or heavy machinery need to be moved.

Low Headroom Gantry Cranes: Designed for use in facilities with limited vertical space, low headroom cranes maximize lift height by minimizing the crane’s own height. This makes them ideal for indoor environments such as workshops and assembly plants.

Explosion-Proof Gantry Cranes: Used in potentially explosive environments, such as chemical plants or oil refineries, these cranes are engineered to prevent any component from igniting a volatile atmosphere, ensuring safe operations under hazardous conditions.

Corrosion-Resistant Gantry Cranes: These are specifically designed for environments where corrosive substances or extreme weather conditions are prevalent, such as wastewater treatment facilities or marine and offshore applications. They are built with materials and finishes that resist rust and degradation.

Automated Gantry Cranes: Utilizing advanced automation technology, these cranes can operate without manual intervention, enhancing operational efficiency and reducing labor costs. They are particularly useful in high-volume manufacturing settings or in ports where consistency and speed are critical.

Portable Gantry Cranes with Special Features: This category includes portable gantries that are equipped with features like adjustable spans, heights, and treads, allowing them to be customized for specific tasks and to navigate in tight spaces.