Overhead cranes are essential tools in various industrial environments, offering tailored solutions for handling and moving heavy materials. These cranes come in different configurations, each designed to meet specific operational needs and workplace constraints. Understanding the distinct categories of overhead cranes is crucial for selecting the right type to enhance efficiency and safety in operations.

Type of Overhead Crane

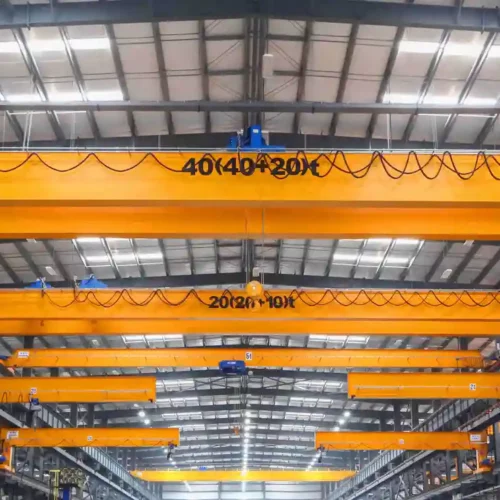

Bridge Cranes: Feature a hoist that runs along a bridge between two parallel runways. These are common in manufacturing environments.

Gantry Cranes: Similar to bridge cranes, but the bridge is supported by legs mounted on wheels or rails. Suitable for outdoor use.

Jib Cranes: Consist of a horizontal jib or boom that supports a moveable hoist. They are fixed to a wall or floor-mounted pillar.

Monorail Cranes: Feature a single rail system; ideal for processes requiring linear movement of materials.

Workstation Cranes: Designed for lighter loads and more repetitive tasks, often found in smaller workspaces.

Capacity

Light Duty: Up to 2 tons. Ideal for light assembly operations or repair shops.

Medium Duty: 2 to 10 tons. Suitable for machine shops and general industrial applications.

Heavy Duty: Over 10 tons. Used for large scale lifting tasks in heavy manufacturing or construction.

Control Method

Manual: Operated by hand, suitable for very light loads and infrequent use.

Electric: Controlled electrically, most common due to their ease of use and capability to handle larger loads.

Remote-Controlled: Allows operation from a distance, enhancing safety and visibility.

Application

Automotive: For assembly lines or handling of automotive parts.

Construction: For moving materials on construction sites.

Manufacturing: For assembly lines, warehousing, and material handling.

Shipping & Logistics: For loading and unloading goods in ports and docks.

Configuration

Single Girder: One main bridge; ideal for lighter loads and shorter spans.

Double Girder: Two parallel bridge beams; suited for heavy loads and long spans.

Features

Adjustable Speed: Can vary the speed for different operations.

Variable Frequency Drives (VFD): For precision control of motor speed and torque.

Automated Systems: Integrated with automated production systems for synchronized operation.

Safety Features: Include overload sensors, emergency stops, and anti-collision devices.

Understanding these categories helps in selecting the right overhead crane for specific needs based on operational requirements and environmental conditions.