1 ton crane Safety Certifications

A 1-ton crane’s safety and proper operation are paramount, necessitating adherence to specific safety certifications and standards. Here’s a concise overview:

Key Safety Certifications and Standards:

1. OSHA (Occupational Safety and Health Administration):

– OSHA establishes regulations for workplace safety in the U.S., including crane operations. Standards such as OSHA 1910.179 (Overhead and Gantry Cranes) provide guidance on safe operation practices.

2. ASME (American Society of Mechanical Engineers):

– ASME B30.2: For overhead and gantry cranes, this standard covers requirements for design, construction, installation, inspection, testing, maintenance, and operation.

– ASME B30.16: Pertains to underhung hoists, which are often integrated with small cranes.

3. ANSI (American National Standards Institute):

– ANSI provides additional guidelines, particularly around safety and performance, complementing ASME standards.

4. ISO (International Organization for Standardization):

– ISO 4306: Terminology for cranes.

– ISO 9927: Periodic inspection requirements, critical for maintaining crane safety over time.

5. CE Marking:

– For cranes in Europe, the CE marking ensures they meet safety, health, and environmental protection requirements as stipulated by EU regulations.

Additional Considerations:

– Manufacturer Compliance: Ensure the crane manufacturer complies with relevant certifications and standards. Review documentation and certification labels.

– Regular Inspections and Maintenance: Adhere to scheduled inspections and maintenance routines as outlined by standards like ASME B30 and ISO 9927.

– Operator Training and Certification: Properly train and certify operators as per OSHA and other relevant standards to ensure safe handling.

– Load Testing: Conduct regular load testing to ensure the crane can safely manage its rated capacity under operating conditions.

By adhering to these key safety standards and certifications, the safe operation of a 1-ton crane can be ensured, thereby minimizing risks to personnel and equipment.

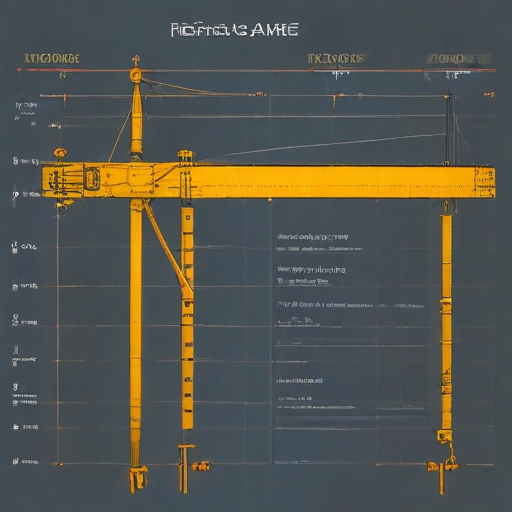

List Reference Technical Parameters of “1 ton crane”

Sure, here are the reference technical parameters for a 1-ton crane, designed to provide a quick overview of its capabilities and specifications:

1. Rated Load Capacity:

– 1 ton (1000 kg)

2. Lifting Height:

– Varies depending on the crane design; typically ranges from 3 to 12 meters.

3. Span:

– The width the crane can cover, generally from 2 to 10 meters in small cranes.

4. Lifting Speed:

– Approximately 8 to 10 meters per minute.

5. Trolley Speed:

– Around 20 to 30 meters per minute.

6. Crane Traveling Speed:

– Typically between 20 to 50 meters per minute.

7. Power Supply:

– AC 380V/50Hz/3Ph (can vary based on regional standards)

8. Motor Power:

– Lifting Motor: Around 1.5 to 3 kW.

– Trolley Motor: Approximately 0.4 to 1 kW.

– Traveling Motor: Close to 0.8 to 1.5 kW.

9. Control Method:

– Options include pendant control, remote control, and the cabin (driver’s) control.

10. Structural Design:

– May include single or double girder configurations.

11. Duty Class/Work Rating:

– Generally, ranges from A3 to A5, indicating its suitability from light to moderate duty use.

12. Hook Approach:

– The minimum distance between the hook and the crane structure; typically minimal to maximize lift reach.

13. Safety Features:

– Overload protection, end limit switches, emergency stop, and anti-collision devices.

14. Ambient Conditions:

– Typically can operate between -20°C to 40°C. Specific ranges might depend on design specifications.

15. Installation Requirements:

– Generally requires a substantially flat and secure foundation, or specific fixing arrangements depending on whether it’s ceiling-mounted, wall-mounted, or freestanding.

These parameters outline the core characteristics you’ll encounter with a standard 1-ton crane, ensuring it aligns with operational, safety, and application needs.

List Product features of “1 ton crane”

Certainly! Here is a list of product features for a 1-ton crane:

1. Lifting Capacity: Can handle loads up to 1 ton (2000 pounds or approximately 907 kilograms).

2. Durability: Constructed from robust materials such as high-grade steel for enhanced strength and longevity.

3. Versatility: Suitable for diverse applications including construction, manufacturing, warehousing, and workshops.

4. Compact Design: Space-efficient design for use in constrained environments without sacrificing performance.

5. Adjustable Boom: Features an adjustable boom for varied lifting heights and reach, offering greater flexibility in handling different operations.

6. Smooth Operation: Equipped with high-quality bearings and gears to ensure smooth and efficient raising and lowering of loads.

7. Safety Features: Includes essential safety mechanisms like overload protection, automatic brake systems, and emergency stop capabilities.

8. Ease of Assembly: Generally easy to assemble and dismantle, allowing for convenient transportation and storage when not in use.

9. Mobility: Often fitted with durable wheels or casters for easy movement and repositioning within a workspace.

10. Control Options: Provides both manual and powered control options, such as hand-operated pulleys or electric hoists, for varying operational requirements.

11. Height Adjustment: Telescoping or height-adjustment capability to cater to different lifting needs and ensure optimal usage across various tasks.

12. Swivel Hook: Equipped with a 360-degree swivel hook for precise positioning and secure attachment of loads.

13. Load Indicator: Some models include a load indicator to monitor weight and ensure the crane is not overloaded.

14. Weather-Resistant Finish: Features a weather-resistant finish to shield against elements, prolonging the crane’s operational life in outdoor environments.

15. User-Friendly Design: Engineered for ease of use, reducing the physical strain on operators and enhancing productivity.

16. Customizable Options: Available with customizable features and accessories to meet specific worksite requirements and improve overall efficiency.

These features collectively contribute to the functionality, reliability, and versatility of a 1-ton crane, making it an indispensable tool for a variety of lifting and handling operations.

List Various Types of “1 ton crane”

Certainly! A “1 ton crane” refers to a crane with a lifting capacity of 1 ton (approximately 2,000 pounds or 907 kilograms). Below are various types of 1 ton cranes commonly used in different lifting and material handling applications:

1. Jib Cranes

– Wall-Mounted Jib Crane: Attached to a wall or column, allowing for a 180-degree range of movement.

– Freestanding Jib Crane: Supported by a fixed base, allowing for a 360-degree range of movement.

– Articulating Jib Crane: Features multiple pivot points for greater flexibility and range of motion.

2. Gantry Cranes

– Adjustable Height Gantry Crane: Height can be adjusted to accommodate different lifting needs.

– Portable Gantry Crane: Equipped with casters for easy movement around a workspace.

– Fixed Height Gantry Crane: Static height, providing consistent lifting capabilities.

3. Overhead Cranes

– Single Girder Overhead Crane: Features a single bridge girder supported by end trucks, ideal for light-duty lifting.

– Underhung Crane: Suspended from the ceiling, allowing for maximum floor space utilization.

– Top Running Overhead Crane: Travels on top of a runway system, suitable for high-clearance areas.

4. Portable Cranes

– Engine Hoist (Cherry Picker): Commonly used in automotive repair for lifting engines and other heavy components.

– Portable Gantry Crane: Easily assembled and disassembled for transport to different job sites.

5. Monorail Systems

– Standard Monorail Crane: Runs on a single stationary rail, ideal for linear path lifting.

– Curved Monorail System: Capable of navigating curves, providing greater flexibility for complex lifting routes.

6. Service Cranes

– Truck-Mounted Crane: Installed on a truck bed, used for lifting tasks in various locations.

– Workshop Crane: Compact design for lifting within confined spaces like workshops or garages.

Each type of 1 ton crane is designed to meet specific lifting requirements, offering versatility, mobility, and ease of use in various industrial, construction, and maintenance settings.

List Application of “1 ton crane”

A 1-ton crane is a versatile lifting device capable of handling loads up to 2,000 pounds. Its applications span various industries due to its moderate lifting capacity and compact design. Here are some key applications:

1. Manufacturing and Assembly Lines:

– Used for material handling and movement of heavy components.

– Facilitates the assembly of machinery and equipment.

2. Warehousing and Distribution:

– Crucial for loading and unloading goods.

– Aids in organizing and stacking heavy inventory items.

3. Construction Sites:

– Ideal for lifting and positioning smaller construction materials and equipment.

– Assists in the assembly of structural elements in confined spaces.

4. Automotive Workshops:

– Used for lifting engines, transmissions, and other heavy automotive components.

– Helps in precision placement during repairs or assembly.

5. Shipyards and Docks:

– Employed for handling cargo and smaller ship components.

– Assists in maintenance by lifting and positioning parts.

6. Mining Operations:

– Useful for lifting mining equipment and materials.

– Facilitates the movement of extracted resources.

7. Agriculture:

– Helps in lifting and transporting heavy farm equipment and supplies.

– Aids in the assembly and maintenance of agricultural machinery.

8. Utilities and Maintenance:

– Used for lifting heavy maintenance equipment and components.

– Assists in the installation and repair of utility infrastructure.

9. Events and Exhibitions:

– Employed for setting up heavy stages, lighting rigs, and other equipment.

– Facilitates the quick assembly and dismantling of event setups.

The 1-ton crane’s moderate lifting capacity and adaptability make it an essential tool across multiple sectors, enabling efficient and safe handling of heavy items in various operational contexts.

List Buyer Types of “1 ton crane”

When considering the purchase of a 1-ton crane, potential buyer types span various industries and purposes. Here are the primary buyer categories:

1. Manufacturing Industry

– Small to Medium Factories: These buyers utilize cranes to move materials, components, or finished products efficiently within the factory setting.

– Assembly Lines: Companies with assembly lines require cranes for positioning parts during the assembly process.

2. Construction Companies

– On-Site Material Handling: These firms use 1-ton cranes to lift and place construction materials such as steel beams, pipes, and prefab components, especially in areas with spatial and weight restrictions.

– Maintenance and Repairs: Cranes are used for maintaining and repairing equipment on construction sites.

3. Warehousing and Logistics

– Material Handling and Storage: Warehouses employ cranes for the efficient handling of heavy goods, pallets, and containers, optimizing space and reducing manual labor.

– Loading and Unloading: Logistics companies use cranes to load and unload heavy goods from trucks and shipping containers.

4. Service and Maintenance Providers

– Industrial Equipment Maintenance: Companies offering maintenance services for industrial machinery use 1-ton cranes for the safe lifting and positioning of heavy components.

– HVAC Installers: Heating, ventilation, and air conditioning firms use cranes to install and service heavy units in commercial buildings.

5. Workshops and Small-Scale Fabrication

– Metal Fabricators: Small workshop operators and artisans use cranes to handle heavy metal sheets and finished products.

– Automotive Repair Shops: Some larger automotive garages need cranes for lifting engines and other heavy automotive parts.

6. Agricultural Operations

– Farm Equipment Handling: Farms use cranes for maintaining and moving heavy equipment such as tractors and combine harvester parts.

7. Marine and Docks

– Boat Maintenance: Marinas and dockyards use cranes for boat repairs and handling marine equipment.

8. Renewable Energy Sector

– Wind and Solar Farms: Companies in renewable energy industries might use cranes for installing and maintaining equipment like solar panels and wind turbine components.

9. Educational and Training Institutions

– Technical and Vocational Schools: Institutions offering courses in mechanical engineering and related fields use 1-ton cranes for practical training purposes.

These buyer types illustrate the diverse applications and sectors where a 1-ton crane can significantly enhance operational efficiency.

List “1 ton crane” Project Types for Different Industries

A 1-ton crane is a versatile lifting device used across various industries for different project types. Here are some common applications categorized by industry:

Manufacturing

1. Assembly Line Operations:

– Moving components between assembly stations

– Installing heavy parts onto machinery

2. Material Handling:

– Transporting raw materials to production areas

– Loading and unloading finished goods

Construction

1. Small-Scale Building:

– Lifting construction materials like steel beams, glass panels, and tiles

– Hoisting HVAC units and other large installations

2. Site Preparation:

– Removing debris and placing landscaping materials

– Positioning concrete forms and molds

Warehousing and Logistics

1. Inventory Management:

– Organizing and storing heavy inventory on high shelves

– Retrieving and restocking bulky items from storage

2. Loading and Unloading:

– Moving freight on and off transport vehicles

– Sorting and transferring heavy packages within the warehouse

Energy and Utilities

1. Equipment Installation:

– Positioning generators, transformers, and other heavy equipment

– Installing solar panels and wind turbine components

2. Maintenance and Repair:

– Replacing worn-out parts in power plants

– Lifting and adjusting utility poles and cables

Automotive

1. Vehicle Assembly:

– Hoisting engines and other heavy components during vehicle assembly

– Installing heavy-duty tires and chassis components

2. Maintenance:

– Removing and replacing engine blocks

– Handling transmissions and drive shafts

Pharmaceuticals and Chemicals

1. Mixing and Blending:

– Handling large mixers and storage tanks

– Transferring bulk raw materials to processing areas

2. Maintenance:

– Installing and maintaining HVAC and sterilization units

– Moving heavy laboratory equipment

Marine and Shipbuilding

1. Dockside Operations:

– Loading and unloading cargo from ships

– Transferring ship components during constructions and repairs

2. Maintenance:

– Hoisting engines and heavy machinery for repair and maintenance

– Positioning large parts during ship retrofitting

A 1-ton crane’s adaptability makes it an indispensable tool across diverse projects in multiple industries, offering efficiency and safety in handling heavy loads.

1 ton crane Accessories Upgrades and Custom Manufacturing Options

Upgrading and customizing a 1-ton crane can significantly enhance its performance, safety, and usability. Here are some popular accessories, upgrades, and manufacturing options to consider:

Accessories:

1. Remote Control Systems: Improve operator safety and precision with wireless remote controls that allow for operation from a safe distance.

2. Load Weighing Systems: Integrated scales provide real-time load weight measurements to prevent overloading and increase accuracy.

3. Lifting Magnets: Ideal for handling ferrous materials, enhancing the crane’s utility in metalworking industries.

4. Hoist Upgrades: Electric or manual hoists can be optimized for smoother operations or increased lifting speeds.

Safety Features:

1. Overload Protection: Systems that automatically halt operations if a load exceeds the crane’s safe capacity.

2. Anti-Collision Sensors: Use sensors to prevent collisions, especially in environments where multiple cranes operate.

3. Limit Switches: Prevent the crane from moving beyond its designated path, ensuring operational safety and equipment longevity.

Custom Manufacturing Options:

1. Tailored Boom Lengths: Custom boom lengths to suit specific work environments and operational needs.

2. Specialized Hooks: Custom-designed hooks for particular lifting requirements like heavy-duty or ultra-precision tasks.

3. Material Options: Use higher-grade steel or lightweight but strong materials like aluminum alloys for enhanced durability and performance.

4. Ergonomic Controls: Custom-designed control panels to reduce operator fatigue and improve control accuracy.

Environmental Enhancements:

1. Weatherproofing: Specialized coatings and seals for outdoor applications to protect against harsh weather conditions.

2. Noise Reduction: Upgraded components and materials designed to minimize operational noise, suitable for residential or noise-sensitive areas.

By integrating these accessories and custom manufacturing options, a 1-ton crane can be precisely aligned with the specific needs of its operational environment, offering enhanced efficiency, safety, and durability.

List Quality Control and The Manufacturing Process of “1 ton crane”

Quality Control and Manufacturing Process of a 1 Ton Crane

Manufacturing Process:

1. Design and Engineering:

– CAD software is used to create detailed specifications and technical drawings.

– Structural analysis ensures the design meets safety and regulatory standards.

2. Material Selection:

– High-grade steel and other durable materials are selected for structural components.

– Electrical and mechanical parts are sourced from reputable suppliers.

3. Fabrication:

– Steel cutting: Laser or plasma cutting machines shape components.

– Welding: MIG/TIG welding assembles the crane structure.

– Machining: CNC machines detail components, creating slots, holes, and fitting points.

4. Pre-assembly:

– Components like the jib, base, and hoist mechanisms are pre-fitted to ensure compatibility and precise alignment.

5. Surface Treatment:

– Sandblasting removes impurities.

– Anti-corrosion treatments and powder coating or painting are applied for durability.

6. Assembly:

– The crane is fully assembled, integrating the mechanical and electrical systems.

– Bolts and fasteners are torqued to specified tolerances.

7. Installation of Electrical Systems:

– Wiring is installed, and control panels and safety systems are tested.

8. Testing and Calibration:

– Load testing ensures the crane can handle 1 ton safely.

– Functional testing checks all movements and safety features.

Quality Control:

1. Incoming Material Inspection:

– Raw materials and components are inspected for quality and compliance with specifications.

2. In-process Inspection:

– Welds and machined parts are checked for defects during fabrication.

– Dimensional checks ensure parts fit precisely.

3. Non-destructive Testing (NDT):

– Techniques like ultrasonic or magnetic particle testing inspect welds and critical parts.

4. Load Testing:

– The assembled crane is subjected to load tests above its rated capacity to verify performance.

5. Final Inspection:

– Visual checks and functional testing ensure the fully assembled crane’s operational efficiency.

– Safety features, electrical systems, and controls are verified.

6. Documentation and Certification:

– Quality assurance reports and compliance certificates are generated.

– User manuals and maintenance guidelines are provided.

By adhering to rigorous quality control processes and precise manufacturing steps, the 1-ton crane is ensured to be safe, reliable, and durable.

How to use “1 ton crane”

Using a 1-ton crane involves several steps to ensure safety and efficiency. Here’s a concise guide:

Preparation

1. Training: Ensure you are trained and familiar with crane operations.

2. Inspection: Check the crane for any damages or malfunctions. Inspect the hook, rope, and other components.

3. Load Limit: Verify that the load does not exceed the crane’s 1-ton capacity.

Operation

1. Positioning: Place the crane on a stable, level surface.

2. Secure the Load:

– Attach the lifting hook or sling to the load securely.

– Double-check all connections and ensure the load is balanced.

3. Hoisting:

– Use the control mechanism (manual or remote) to lift the load slowly.

– Elevation should be gradual to avoid swinging or jerking.

4. Movement:

– Once the load is lifted, move the crane smoothly to transport the load.

– Maintain a steady pace and avoid sudden movements.

5. Lowering:

– Gradually lower the load to the desired location.

– Ensure no part of the body is under the load during this process.

Safety Tips

1. Clear Area: Ensure the surrounding area is free of obstructions and people.

2. Communication: Use clear signals or communication methods with team members.

3. Shutdown: After completing the task, turn off and secure the crane.

Post-Operation

1. Inspection: Perform a final check for any wear and tear.

2. Maintenance: Follow the manufacturer’s guidelines for regular maintenance.

By following these steps, you can operate a 1-ton crane efficiently and safely.

“1 ton crane” Comparative Analysis

Certainly! A “1 ton crane” refers to a crane with a lifting capacity of one ton (2,000 pounds or approximately 907 kilograms). When comparing 1 ton cranes, factors like type, operational scope, and features are crucial.

1. Types of 1 Ton Cranes:

– Overhead Cranes: Commonly found in industrial environments, these cranes are mounted on overhead beams. They are ideal for repetitive lifting tasks within confined spaces. They boast high precision and can be automated for efficiency.

– Jib Cranes: Typically floor or wall-mounted, jib cranes offer localized lifting capability within a specific radius. They are beneficial for smaller workshops with limited space.

– Portable Cranes: These include models like gantry cranes which are movable and can be used outdoors or indoors. They provide flexibility for job sites that change frequently.

2. Operational Scope:

– Industrial Use: Overhead and jib cranes are predominant for indoor industrial applications, such as moving heavy machinery or construction materials within a factory setting.

– Maintenance & Repair: Portable cranes excel in maintenance tasks, offering mobility to reach various sections of a facility or multiple sites.

3. Key Features:

– Power Source: They can be electric, hydraulic, or manual. Electric cranes are efficient and require less manual effort, while manual cranes are cost-effective but labor-intensive.

– Control Systems: Modern 1 ton cranes often come with remote or pendant controls, enhancing safety and ease of use.

– Durability and Construction: Steel construction provides robustness, but aluminum variants may offer weight advantages for portability.

Conclusion:

Selecting the right 1 ton crane involves analyzing the type of crane that fits the environment, the operational needs, and critical features like power source and control systems. Overhead cranes and jib cranes are ideal for fixed, repetitive tasks, while portable cranes offer flexibility for varied job sites. Understanding these aspects ensures optimal performance and safety in lifting operations.

“1 ton crane” Warranty and Support

When purchasing a 1-ton crane, it is crucial to consider the warranty and support options offered by the manufacturer or supplier.

Warranty: Most reputable manufacturers provide a comprehensive warranty that typically ranges from 1 to 3 years, covering defects in materials and workmanship. The warranty often includes specific terms and conditions, such as proper use and routine maintenance requirements. Some warranties may also cover certain parts replacement or repairs, depending on the issue encountered. Be sure to read the warranty documentation carefully to understand what is and isn’t covered, and remember to register your equipment to activate the warranty.

Support: After-sales support is an essential aspect to consider. Look for companies that offer robust support services, including:

1. Customer Service: Reliable customer service should be available to assist with any inquiries or issues. Most companies offer multiple contact options, including phone, email, and online chat.

2. Technical Support: Access to a team of skilled technicians who can provide troubleshooting assistance and resolve technical issues is vital. Some manufacturers offer remote support services, while others may provide on-site assistance if needed.

3. Spare Parts Availability: Ensure that spare parts are readily available. A good supplier will have an efficient supply chain to minimize downtime in case parts need replacement.

4. Maintenance Services: Some companies offer maintenance contracts or services to help keep your crane in optimal working condition, which can be beneficial in prolonging the lifespan of the equipment.

5. User Manuals and Training: Comprehensive user manuals and training resources should be provided to ensure proper operation and safety. Some suppliers may also offer training sessions or workshops.

In summary, when investing in a 1-ton crane, carefully review the warranty terms and seek a supplier that provides robust support services. This will ensure that your equipment remains reliable and any issues are promptly addressed, safeguarding your investment.

List “1 ton crane” FAQ

1 Ton Crane FAQ

1. What is a 1 ton crane?

A 1 ton crane is a lifting device with a maximum lifting capacity of one ton (2,000 pounds). It’s used to move heavy materials easily and safely.

2. What types of 1 ton cranes are available?

Common types include overhead (bridge) cranes, jib cranes, gantry cranes, and portable cranes. Each type serves different environments and purposes.

3. Where can 1 ton cranes be used?

They are suitable for various settings such as warehouses, workshops, construction sites, and production facilities.

4. How do I choose the right 1 ton crane?

Consider factors like the working environment, type of load, lifting height, span, and the crane’s mobility requirements.

5. What safety measures should I take when using a 1 ton crane?

Always follow the manufacturer’s guidelines, conduct regular inspections, ensure proper load balancing, and provide operator training. Use safety equipment like harnesses and load chains.

6. How often should a 1 ton crane be inspected?

Periodic inspections vary by usage but generally should be done daily for basic checks, monthly for detailed examinations, and annually for comprehensive assessments.

7. Can a 1 ton crane be customized?

Yes, many manufacturers offer customization options to fit specific needs such as adjustable heights, spans, and different mounting types.

8. What is the average cost of a 1 ton crane?

Costs vary widely based on the type and features but generally range from $2,000 to $10,000. Complex systems with advanced features may be more expensive.

9. What are the benefits of using a 1 ton crane?

Improved efficiency, enhanced safety, reduced labor costs, and increased productivity by automating heavy lifting tasks.

10. Do 1 ton cranes require special maintenance?

Regular maintenance such as lubrication, checking for wear and tear, and ensuring operational efficiency is crucial to extend the crane’s lifespan and ensure safety.

11. Can a 1 ton crane be used outdoors?

Some models are designed for outdoor use, but it’s essential to check with the manufacturer for weather-resistant features and suitability for your specific outdoor conditions.

12. Are there any legal requirements for operating a 1 ton crane?

Regulations vary by region; operators may need certifications, and the crane itself must meet safety standards set by relevant authorities (e.g., OSHA in the USA).

This concise FAQ is designed to provide an overview of 1 ton cranes, addressing common queries effectively.

Top 10 FAQ with answer about 1 ton crane for Buyer Sourcing from China

Sure! Here are the top 10 frequently asked questions (FAQs) with answers for buyers sourcing a 1-ton crane from China:

1. What is the capacity of a 1-ton crane?

– A 1-ton crane is designed to lift loads up to 1 ton or 1,000 kilograms.

2. What types of 1-ton cranes are available?

– Common types include overhead cranes, gantry cranes, jib cranes, and portable cranes. Each type has specific applications and advantages.

3. What are the key features to consider when buying a 1-ton crane?

– Consider features such as lifting height, span, crane speed, control system, and durability. Also, ensure compliance with safety standards.

4. How can I ensure the quality of a 1-ton crane from China?

– Look for ISO and CE certifications. Request quality assurance documents and consider third-party inspections. Check for reviews and testimonials from other buyers.

5. What is the lead time for a 1-ton crane from China?

– Lead times typically range from 4 to 8 weeks, depending on the complexity and customization requirements. Always confirm with your supplier.

6. How much does a 1-ton crane cost?

– Prices vary based on type, features, and brand but generally range from $2,000 to $10,000. Get multiple quotes for a comprehensive comparison.

7. What are the shipping options and costs?

– Options include sea freight, air freight, and express shipping. Costs depend on the crane’s size, weight, and destination. Request shipping quotes from the supplier.

8. Are there any import duties or taxes?

– Yes, import duties and taxes vary by country. Consult with a customs broker or logistics provider to understand these costs.

9. What after-sales services are provided?

– Suppliers typically offer warranties (commonly 1 year), spare parts, and technical support. Confirm these details before purchasing.

10. How do I handle installation and training?

– Many suppliers offer installation guides or on-site service. Training can be provided through manuals, videos, or supplier technicians. Clarify these arrangements beforehand.

This concise guide aims to provide the essential information needed for sourcing a 1-ton crane from China. Always conduct due diligence to ensure a smooth purchasing process.