100 ton crane Safety Certifications

Safety certifications for a 100-ton crane are crucial for ensuring safe operation and compliance with industry standards. Key certifications include:

1. OSHA Compliance (Occupational Safety and Health Administration):

– OSHA standards regulate crane operations in the United States under 29 CFR 1926 Subpart CC. All cranes must meet these safety guidelines to ensure safe lifting, rigging, and operation practices.

2. ANSI Certification (American National Standards Institute):

– ANSI B30 standards provide guidelines for crane operation, maintenance, and inspection. These standards are essential for minimizing the risk of accidents and ensuring crane reliability.

3. CMAA Certification (Crane Manufacturers Association of America):

– CMAA specifies design, inspection, and maintenance standards. Cranes adhering to CMAA standards are designed for optimal performance and safety.

4. ISO Certification (International Organization for Standardization):

– ISO 9927 outlines the requirements for crane inspections and maintenance. Compliance ensures the crane operates safely and efficiently.

5. Canadian CSA Standards (Canadian Standards Association):

– For operations in Canada, compliance with CSA Z150 standards is mandatory, covering various aspects of crane safety and operational procedures.

6. Operator Certification:

– Crane operators need personal certification through agencies like NCCCO (National Commission for the Certification of Crane Operators). This ensures operators are knowledgeable about safe practices and competent in handling crane operations.

7. Periodic Inspections:

– Frequent and thorough inspections are required, including daily, monthly, and annual checks as per the crane’s operational guidelines. These inspections help in early identification and mitigation of potential issues.

In summary, adhering to these safety certifications and guidelines ensures that a 100-ton crane operates within safe parameters, minimizing risks and enhancing operational safety. It’s imperative for crane owners and operators to be familiar with and comply with these certifications and regulations.

List Reference Technical Parameters of “100 ton crane”

The technical parameters of a “100-ton crane” can vary based on the manufacturer and the specific model, but here are some common reference technical parameters one might typically encounter:

1. Lifting Capacity: 100 metric tons (220,462 pounds).

2. Boom Length:

– Main Boom: Typically ranges from 12 to 60 meters (39 to 196 feet).

– Jib (Optional): Additional jib lengths can extend reach up to 20 meters (65 feet).

3. Height of Lift:

– Maximum Lifting Height (with Jib): Up to 80 meters (262 feet).

4. Boom Extension: Hydraulically or mechanically extendable sections.

5. Outreach (Radius): Maximum working radius can vary, up to 40 meters (130 feet) or more depending on the boom length and load weight.

6. Slewing Range: 360 degrees continuous rotation.

7. Travel Speed: Depends on the crane type (e.g., truck-mounted, all-terrain):

– Truck-mounted: Up to 80 km/h (50 mph).

– All-terrain: Up to 40 km/h (25 mph).

8. Stabilizers (Outriggers):

– Spread: Typically up to 8 meters (26 feet).

9. Engine Specifications:

– Power: Ranges between 200-400 kW (268-536 hp).

– Type: Diesel, often with turbocharging for better efficiency.

10. Hydraulic System:

– Pressure: Up to 350 bar (5,076 psi).

– Flow Rate: Variable, typically up to 300 liters per minute (79 gallons per minute).

11. Control Systems:

– Full electronic or hydraulic control with load-moment indicators (LMI).

– Remote control options available on advanced models.

12. Dimensions and Weight:

– Overall Length: Approximately 15-20 meters (49-65 feet).

– Width: 3 meters (10 feet).

– Height: 4 meters (13 feet).

– Gross Vehicle Weight: In the range of 40-60 tons (88,185-132,277 pounds), depending on configuration and load.

These parameters provide an overview of a typical 100-ton crane’s capabilities and limitations. Always refer to the specific technical manual of the crane model for precise details and safety guidelines.

List Product features of “100 ton crane”

A 100-ton crane is a heavy-duty piece of machinery designed for lifting and moving extremely heavy loads. Here are the key product features:

1. Load Capacity: The crane can lift up to 100 tons, making it suitable for large-scale industrial, construction, and infrastructure projects.

2. Boom Length and Extensions: Typically equipped with a long, telescopic boom that can reach significant heights and distances, often over 200 feet with additional jib attachments.

3. Mobility: Available in various configurations such as truck-mounted, crawler, or all-terrain, providing flexibility for different job sites and conditions.

4. Powerful Engine: Robust engines, usually diesel, capable of providing the necessary power for both lifting operations and movement.

5. Stabilization Systems: Outriggers and counterweights are essential for maintaining stability during lifts, ensuring safety and precision.

6. Advanced Control Systems: Modern cranes come with computerized controls, load moment indicators (LMI), and safety monitoring systems to enhance operation accuracy and safety.

7. Operator Cab: Ergonomically designed with climate control, wide visibility, and advanced control panels to ensure operator comfort and efficiency.

8. Hydraulic Systems: High-efficiency hydraulic systems enable precise lifting and positioning capabilities, allowing for smoother and safer operations.

9. Boom Options: Use of lattice or telescopic booms to provide versatility for different types of lifts and job requirements.

10. Transport and Setup: Designed for relatively quick assembly and disassembly, facilitating easier transportation between job sites.

11. Safety Features: Multiple safety features, including overload protection, emergency shut-offs, and redundant systems to ensure safe operations.

12. Customization: Options for various attachments and accessories to tailor the crane for specific tasks or industries, enhancing utility and job adaptability.

These features collectively make the 100-ton crane a versatile and indispensable tool for large-scale lifting tasks across various sectors, ensuring efficiency, safety, and reliability.

List Various Types of “100 ton crane”

Sure! Here are various types of 100-ton cranes, each designed for specific applications and environments:

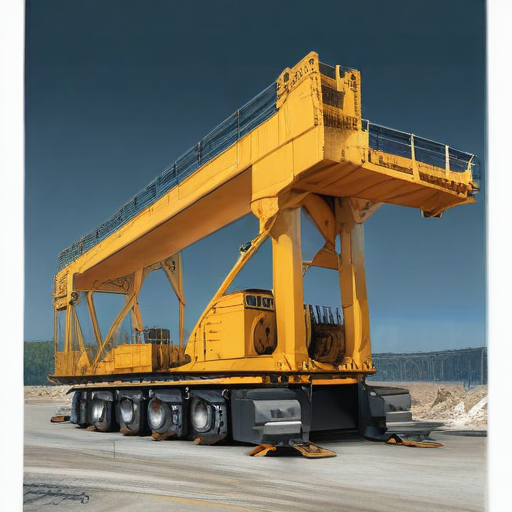

1. Mobile Cranes

– All-Terrain Cranes: Versatile cranes that work well on paved roads and rough terrain. These cranes have large tires and powerful engines, making them ideal for construction sites.

– Rough Terrain Cranes: Designed for off-road operations, featuring four large, heavy-duty tires and a compact, robust frame.

– Truck-Mounted Cranes: Mounted on a truck chassis, these cranes provide excellent mobility and can travel on public roads with ease.

2. Crawlers

– Crawler Cranes: Equipped with tracks instead of wheels, these cranes offer superb stability and can maneuver on soft ground and rough terrain, although they usually require disassembly for transport.

3. Tower Cranes

– Tower Cranes: Commonly used in high-rise building construction, these cranes offer a stable and high reach with their tall towers and long horizontal jib arms. Some specialized models can lift heavy loads up to 100 tons.

4. Carry Deck Cranes

– Carry Deck Cranes: Compact, versatile cranes with a rotating boom and a flat deck for easy loading and transport of materials around job sites.

5. Telescopic Cranes

– Telescopic Boom Cranes: Feature a boom that extends or retracts, providing flexibility in reach and height. They can be mounted on various carriers, including trucks or all-terrain vehicles.

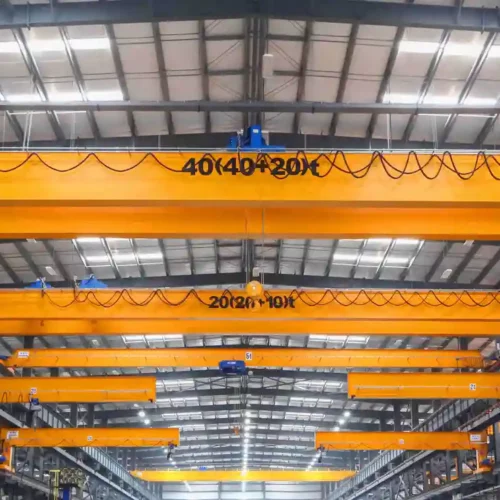

6. Overhead Cranes

– Overhead Gantry Cranes: Often used in industrial settings, such as factories and warehouses, these cranes run along a pair of elevated tracks and can handle significant heavy lifting.

7. Floating Cranes

– Floating Cranes: Used for maritime applications like bridge construction or dockside tasks. They are mounted on barges or pontoons and can handle heavy lifting operations on water.

8. Railroad Cranes

– Railroad Cranes: Designed to travel on railway tracks, these cranes support rail maintenance and construction projects, often equipped with robust lifting and retracting capabilities.

Each type of crane is optimized for different tasks and environments, making them essential tools in various construction, industrial, and maritime applications.

List Application of “100 ton crane”

A 100-ton crane is a powerful piece of heavy equipment used for lifting and moving loads of up to 100 tons. These cranes are versatile and have numerous applications across various industries:

Construction:

1. High-Rise Buildings: Lifting heavy steel beams, concrete panels, and other construction materials to elevated work areas.

2. Bridge Construction: Assembling and placing bridge segments, girders, and other large components.

3. Infrastructure Projects: Assisting in the construction of roads, tunnels, and large transportation structures.

Industrial:

4. Manufacturing Plants: Moving large machinery, plant components, and production materials.

5. Shipbuilding: Lifting and positioning ship sections, engines, and other massive materials in shipyards.

6. Mining: Handling and transporting large pieces of mining equipment and extracted materials.

Energy:

7. Wind Farms: Erecting wind turbine towers, blades, and nacelles at wind farm sites.

8. Oil & Gas: Lifting heavy equipment for offshore platforms, drilling rigs, and refineries.

9. Power Plants: Assisting in the installation and maintenance of large-scale equipment like transformers, boilers, and turbines.

Transportation:

10. Railway: Lifting and placing rail segments, train cars, and maintenance of railway infrastructure.

11. Ports and Harbors: Loading and unloading large shipping containers, bulk materials, and heavy cargo.

Demolition:

12. Destruction and Clean-Up: Removing large debris, dismantling heavy structures, and facilitating the clean-up process after demolition projects.

Emergency Services:

13. Disaster Recovery: Lifting and moving debris in disaster-stricken areas to assist in rescue operations and recovery activities.

Events and Entertainment:

14. Concerts and Shows: Setting up large stages, lighting rigs, and other heavy equipment for major events and concerts.

This extensive versatility makes a 100-ton crane an indispensable asset in any industry that requires the handling of heavy materials and equipment.

List Buyer Types of “100 ton crane”

Purchasers of a 100-ton crane typically fall into several distinct categories, each with specific needs and use cases. The major buyer types include:

1. Construction Companies: These businesses often need heavy cranes for constructing large infrastructures like buildings, bridges, and industrial facilities. Cranes are essential for lifting heavy materials, structural elements, and machinery into place.

2. Mining and Extraction Firms: Mining companies and other resource extraction operations use heavy cranes to move large pieces of equipment, extracted materials, and to carry out site development tasks.

3. Shipping and Logistics Providers: Ports, shipping companies, and large logistics hubs frequently purchase cranes for loading and unloading heavy cargo from ships, trucks, and trains. These cranes facilitate efficient handling of containers and bulk goods.

4. Manufacturing Plants: Factories that handle large-scale manufacturing processes or produce heavy equipment often invest in cranes to transport raw materials, heavy machinery, and finished products within the facility and for shipment.

5. Rentals and Leasing Companies: These firms buy cranes to lease them to businesses that need heavy lifting capabilities on a temporary basis. This allows smaller companies or those with sporadic needs to access crane services without the capital investment.

6. Utilities and Energy Companies: Businesses in the energy sector, including oil, gas, and renewable energy companies, require cranes for the construction and maintenance of facilities like pipelines, wind turbines, and power plants.

7. Infrastructure Development Firms: Companies involved in large-scale infrastructure projects, such as highway construction, rail projects, and airport development, frequently purchase heavy cranes for their substantial lifting requirements.

8. Government and Municipal Agencies: Agencies responsible for public works and infrastructure maintenance may purchase cranes for constructing and maintaining roads, bridges, and public buildings.

Each of these buyer types has specific requirements related to crane capacity, mobility, and operational reach, tailored to their unique operational demands.

List “100 ton crane” Project Types for Different Industries

A 100-ton crane is versatile and powerful, suitable for a variety of industries. Here are some common project types where such a crane is utilized:

Construction Industry

1. High-Rise Building Construction: Lifting heavy materials like steel beams, precast concrete components, and large equipment to significant heights.

2. Bridge Construction: Installing large bridge segments, support beams, and other heavy infrastructure components.

3. Commercial Building Development: Transporting HVAC units, generators, and substantial structural elements during the construction process.

Oil & Gas Industry

1. Rig Assembly and Maintenance: Lifting drilling equipment, subsea components, and sections of oil rigs both onshore and offshore.

2. Pipeline Installation: Transporting and positioning large pipeline sections and associated heavy machinery.

Infrastructure Development

1. Railway Construction: Handling railway sleepers, tracks, and signaling equipment. Crucial for laying and maintaining tracks.

2. Large Signage Installation: Deploying large highway and roadway signs.

Shipping & Logistics

1. Port Operations: Loading and unloading heavy cargo containers, vehicles, and bulk goods from ships.

2. Warehouse Management: Moving and stacking heavy inventory and machinery within large storage facilities.

Power Generation

1. Wind Turbine Installation: Assembling and lifting heavy wind turbine components like nacelles and blades.

2. Power Plant Construction: Installing large boilers, turbines, and transformers within power generation facilities.

Mining Industry

1. Equipment Relocation: Transporting heavy mining equipment and components within the mining site.

2. Site Set-Up: Establishing large-scale facilities and infrastructure necessary for mining operations.

Aerospace

1. Aircraft Construction and Maintenance: Handling large aircraft parts and conducting maintenance tasks involving heavy components.

2. Satellite Launch Preparation: Transporting and positioning large satellite launch vehicles and equipment.

This spread of industry-specific applications showcases the extensive utility of a 100-ton crane, highlighting its indispensable role in heavy lifting and material handling across varied fields.

100 ton crane Accessories Upgrades and Custom Manufacturing Options

Upgrading a 100-ton crane and enhancing its capabilities with accessories and custom manufacturing options can significantly improve operational efficiency and versatility. Here are some key options:

1. Load Monitoring Systems: Installing advanced load monitoring systems enhances safety by providing real-time data on load weights and movement, preventing overloading and potential accidents.

2. Remote Controls: Remote control systems allow operators to operate the crane safely from a distance, improving precision and reducing the risk of accidents in hazardous environments.

3. Anti-Sway Technology: Anti-sway systems minimize load swing, ensuring safer and more stable lifting operations, particularly in challenging conditions or with delicate loads.

4. Custom Lifting Attachments: Customizable lifting attachments, such as spreader beams, lifting magnets, and specialized hooks, can be designed to cater to specific operational needs, improving flexibility and load management.

5. Hydraulic Upgrades: Enhancing the hydraulic system with high-efficiency components can improve lifting speed and precision, reducing operation time and increasing productivity.

6. Boom Extensions and Jibs: Custom-designed boom extensions and jibs can increase the reach and versatility of the crane, allowing it to handle a wider range of tasks.

7. Hoist Upgrades: Upgrading to a higher-capacity or faster hoist can improve lifting performance and cycle times, making operations more efficient.

8. Weatherproofing and Environmental Protection: Adding protective coatings and weatherproofing solutions can extend the crane’s operational life and reliability in harsh conditions.

9. Automation and Smart Controls: Integrating automation and smart control systems can streamline operations, improve accuracy, and reduce manual intervention, leading to greater efficiency and safety.

10. Custom Paint and Branding: Custom paint jobs and branding not only enhance the crane’s appearance but also ensure it aligns with company identity and promotes corporate image.

By investing in these accessories and custom manufacturing options, a 100-ton crane can be tailored to meet specific operational needs, enhance performance, and ensure higher safety standards, ultimately leading to increased productivity and cost savings.

List Quality Control and The Manufacturing Process of “100 ton crane”

Sure, here’s a concise overview of the quality control and manufacturing process of a 100-ton crane:

Quality Control:

1. Design Verification:

– Detailed simulations and finite element analysis are performed.

– Compliance with safety regulations and industry standards (e.g., ASME, ISO).

2. Material Testing:

– Raw materials are tested for strength, durability, and resistance to environmental factors.

– Certificates of conformity from suppliers are reviewed.

3. Component Inspection:

– Key components like hydraulic systems, motors, and structural components undergo rigorous inspection.

– Non-destructive testing (NDT) such as ultrasonic, radiographic, or magnetic particle testing is used.

4. Assembly Checks:

– Precision alignment and tolerance checks during assembly.

– Real-time monitoring systems to track assembly parameters.

5. Performance Testing:

– Load testing to ensure the crane can handle 100 tons safely.

– Functional tests for all operational features like boom extension, rotation, and safety mechanisms.

6. Final Inspection:

– Thorough inspection of the entire crane, focusing on welding seams, bolted joints, and hydraulics.

– Painted and coated surfaces are checked for adherence and protection.

Manufacturing Process:

1. Design and Engineering:

– Creating detailed blueprints and 3D models.

– Engineering calculations for load handling and structural integrity.

2. Material Procurement:

– Sourcing high-quality steel, hydraulic components, and electrical systems.

– Strict supplier evaluation and selection.

3. Fabrication:

– Cutting, shaping, and welding of steel plates and sections.

– CNC machining of critical parts for precision.

4. Machining and Assembly:

– Machining of components like gears, shafts, and hydraulic parts.

– Assembly of the crane’s base, boom, and counterweights in a controlled environment.

5. Hydraulic and Electrical Systems Integration:

– Installation of hydraulic hoses, pumps, and actuators.

– Wiring and installation of control systems and sensors.

6. Painting and Coating:

– Application of anti-corrosive coatings and industrial paints.

– Ensuring long-term protection from environmental factors.

7. Final Assembly and Testing:

– Complete assembly of the crane.

– Comprehensive testing for functionality, safety, and load capacity.

8. Delivery and Installation:

– Safe transportation to the client’s site.

– On-site assembly if required, followed by final checks and handover.

How to use “100 ton crane”

Operating a 100-ton crane requires specialized training and strict adherence to safety protocols. Here are the essential steps for using such a crane:

1. Training and Certification: Operators must be trained, certified, and familiar with the specific crane model.

2. Pre-Operation Inspection:

– Check Equipment: Inspect the crane for any signs of wear or damage. Ensure all safety devices are functioning correctly.

– Verify Load Charts: Confirm the crane’s load chart to ensure it can handle the weight and reach required.

3. Site Preparation:

– Assess Ground Conditions: Ensure the ground can support the crane’s weight and stabilize with outrigger pads if necessary.

– Clear Work Area: Remove any obstructions and ensure adequate space for crane operation and swing.

4. Lift Planning:

– Determine Weight and Radius: Accurately measure the load’s weight and the radius from the crane’s center to the load.

– Identify Lift Points: Determine the safest lift points on the load for attachment.

5. Setup:

– Position the Crane: Align the crane with the load and extend outriggers if available.

– Attach Rigging: Use appropriate rigging gear, like slings, shackles, and hooks. Double-check all connections.

6. Safety Protocols:

– Communicate: Maintain clear communication with signal persons and other crew.

– Emergency Procedures: Know and be prepared to execute emergency protocols.

7. Lifting and Moving the Load:

– Lift Smoothly: Gradually lift the load to avoid sudden movements. Monitor for stability.

– Navigate Carefully: Use slow and controlled movements when swinging or placing the load.

8. Post-Operation:

– Secure the Crane: Lower the boom, retract outriggers, and turn off the crane.

– Inspect for Damage: Check the crane and rigging for any damage incurred during operation.

9. Documentation:

– Log Operations: Record details of the lift in the crane’s logbook for maintenance and safety records.

By following these steps, you ensure the safe and efficient use of a 100-ton crane.

“100 ton crane” Comparative Analysis

A “100-ton crane” refers to a crane with a maximum lifting capacity of 100 tons. This term encompasses various types of cranes, differentiated primarily by their design, mobility, and application.

Mobile Cranes

Types:

1. Truck-Mounted Cranes: Offer flexibility and can travel on highways.

2. Rough Terrain Cranes: Designed for off-road construction sites.

3. Crawler Cranes: Utilize tracked undercarriages for stability on uneven terrain.

Advantages:

– Versatility: Can be used in diverse environments.

– Mobility: High efficiency in moving between job sites.

– Setup Time: Quick setup reduces downtime.

Tower Cranes

Applications:

– Primarily used in the construction of tall buildings.

– Erected on-site and used throughout the project duration.

Advantages:

– Height and Reach: Boast impressive vertical and horizontal reach.

– Stability: Anchored to the ground for enhanced load-bearing capability.

Overhead Cranes (Bridge Cranes)

Usage:

– Common in industrial settings like manufacturing plants and warehouses.

– Installed on elevated runways that allow movement across two axes.

Advantages:

– Precision: Offers high degrees of control for precise load placement.

– Load Capacity: Suitable for repeated lifting of heavy loads.

Key Comparative Factors

1. Mobility:

– Mobile cranes excel in transportability.

– Tower and overhead cranes remain stationary after installation.

2. Setup and Teardown Time:

– Mobile cranes are efficient in quick deployment.

– Tower cranes require extensive setup time but offer long-term benefits.

3. Operating Environment:

– Rough terrain cranes are ideal for outdoor, uneven sites.

– Overhead cranes are best for indoor, industrial applications.

4. Lift Height and Outreach:

– Tower cranes provide superior height and outreach, essential for skyscrapers.

– Mobile and overhead cranes are limited by their design but can still manage significant heights and distances.

In summary, the choice of a 100-ton crane depends on the specific needs regarding mobility, environmental conditions, height, and outreach. Mobile cranes offer flexibility, tower cranes provide height advantages, and overhead cranes excel in precise control for industrial applications.

“100 ton crane” Warranty and Support

When considering the purchase of a 100-ton crane, it’s essential to pay close attention to the warranty and support options provided by the manufacturer or supplier. These factors significantly impact the longevity, functionality, and overall cost-effectiveness of the equipment.

Warranty

Typically, a 100-ton crane comes with a standard warranty ranging from one to five years, depending on the manufacturer. This warranty generally covers defects in material and workmanship under normal use and conditions. It’s crucial to understand what components are included in the warranty, such as the boom, hydraulic systems, engine, and electrical parts. Additionally, check for any exclusions or limitations, such as wear and tear components or misuse. Some manufacturers may offer extended warranty options for an additional fee, which can provide added peace of mind and protection.

Support

1. Technical Support: Ensure the manufacturer offers robust technical support. This often includes phone support, online resources, and, in some cases, on-site visits from certified technicians. Quick and efficient technical support can significantly reduce downtime and operational losses.

2. Maintenance Services: Regular maintenance is key to the crane’s longevity. Many suppliers offer maintenance packages that include scheduled inspections, preventive maintenance, and timely repairs. These services help in identifying potential issues before they become major problems.

3. Spare Parts Availability: Access to genuine spare parts is crucial. Confirm that the manufacturer provides an easy and quick way to order parts. Some suppliers even offer next-day shipping to minimize downtime.

4. Training Programs: Operator and technician training programs provided by the manufacturer can ensure the crane is used safely and efficiently. These programs might include initial training upon delivery, as well as ongoing training opportunities.

5. Software Support: If the crane includes advanced software for operations and diagnostics, it’s important that this software is supported with regular updates and troubleshooting assistance.

Understanding the warranty and support services can significantly influence your satisfaction and the long-term performance of your 100-ton crane. Always opt for a manufacturer or supplier with a strong track record in customer service and support.

List “100 ton crane” FAQ

100 Ton Crane FAQ

1. What Can a 100 Ton Crane Lift?

– A 100 ton crane can lift up to 100 tons at its maximum capacity. However, the actual lifting capability depends on the radius (distance from the crane’s center point) and the boom length.

2. What Are the Different Types of 100 Ton Cranes?

– Common types include all-terrain cranes, rough-terrain cranes, crawler cranes, and truck-mounted cranes. Each type has specific applications and benefits.

3. What Are the Typical Applications for a 100 Ton Crane?

– These cranes are used in construction, heavy industry (like petrochemical plants), bridge building, wind energy, and large-scale infrastructure projects.

4. How Do I Determine the Best 100 Ton Crane for My Needs?

– Factors include the type of terrain, the radius of operation, height requirements, frequency of movement, and specific lifting needs.

5. What Are the Safety Considerations When Operating a 100 Ton Crane?

– Safety protocols include regular inspections, operator certification, following load charts, ensuring stable ground conditions, and adherence to manufacturer guidelines.

6. How Is Crane Load Capacity Affected by Boom Length?

– The longer the boom, the less weight the crane can lift. Always refer to the load chart provided by the manufacturer.

7. Do I Need Special Permits to Operate a 100 Ton Crane?

– This depends on local regulations. In most regions, operating such heavy equipment requires specific licenses and permits.

8. What Kind of Maintenance Does a 100 Ton Crane Require?

– Regular maintenance includes checking hydraulic systems, ensuring structural integrity, inspecting cables and rigging, and routine lubrication.

9. How Much Does It Cost to Rent a 100 Ton Crane?

– Costs vary significantly based on location, duration of rental, crane type, and additional services like operator fees and transportation.

10. Can a 100 Ton Crane Be Used Indoors?

– Yes, but it depends on indoor height restrictions and space. Specialized rigging may be required for indoor operations.

By addressing these questions, users can gain a clear understanding of 100 ton cranes, ensuring they select the appropriate equipment for their projects while adhering to safety and regulatory requirements.

Top 10 FAQ with answer about 100 ton crane for Buyer Sourcing from China

Top 10 FAQ About Sourcing a 100 Ton Crane from China

1. What are the key specifications of a 100-ton crane?

– Key specifications include load capacity, boom length, jib length, lifting height, and operational radius. Ensure compatibility with your project needs.

2. What types of 100-ton cranes are available?

– Options include all-terrain cranes, crawler cranes, rough terrain cranes, and truck-mounted cranes. Select depending on the project environment and mobility needs.

3. How do I verify the crane’s quality and authenticity?

– Check for certifications like CE, ISO, and CCC. Inspect before purchase and request test reports or demonstrations.

4. What is the average cost range for a 100-ton crane?

– Prices can vary greatly from $200,000 to $500,000 depending on brand, features, and condition (new or used).

5. Who are the reputable manufacturers in China?

– Leading manufacturers include XCMG, Zoomlion, and SANY. Research each for their global reputation and local support.

6. What is the typical lead time for delivery?

– Expect 30–90 days, influenced by manufacturing times and shipping logistics. Confirm lead time during negotiations.

7. Are spare parts readily available?

– Reputable manufacturers maintain a global supply chain for spare parts. Ensure availability of critical components.

8. What are the warranty terms?

– Warranties typically range from 1 to 2 years covering parts and service. Review specific terms closely.

9. What are the shipping and import costs?

– Costs include freight, insurance, and import duties. Use a reliable freight forwarder and customs broker to manage logistics and reduce surprises.

10. Can training and support be provided?

– Many manufacturers offer operator training, maintenance instructions, and after-sales support. Verify availability and scope before purchase.

When sourcing a 100-ton crane from China, careful consideration of these factors will ensure a smooth and satisfactory acquisition process. Always engage in thorough due diligence and consultations with vendors.