2 ton overhead hoist Safety Certifications

A 2-ton overhead hoist must comply with several safety certifications and standards to ensure safe operation. These certifications vary by country but generally include:

1. ANSI/ASME (American National Standards Institute/American Society of Mechanical Engineers):

– ASME B30.16: This standard covers overhead hoists, including electric, air, hand chain, and lever types.

– ASME B30.11: Addresses monorails and underhung cranes.

2. ISO (International Organization for Standardization):

– ISO 4301-1: Specifies classification for machinery used in lifting.

– ISO 9927-1: Guidelines for the inspection, maintenance, and use of lifting equipment.

3. CE Marking (European Union):

– Indicates compliance with EU safety, health, and environmental requirements.

– Relevant directives include the Machinery Directive (2006/42/EC).

4. CMMA (Crane Manufacturers Association of America):

– Provides guidelines and criteria for the design and manufacturing of overhead cranes and hoists.

5. OSHA (Occupational Safety and Health Administration, USA):

– Enforces standards such as 29 CFR 1910.179 for overhead and gantry cranes.

– Requires regular inspections, training, and maintenance to ensure safety.

6. CSA (Canadian Standards Association):

– CSA B167: Standard for the design, fabrication, and installation of overhead cranes.

7. IEC (International Electrotechnical Commission):

– IEC 60204-32: Safety of machinery related to electrical equipment of hoisting machines.

Regular inspections, adherence to operational guidelines, and preventive maintenance are crucial aspects reinforced by these standards to mitigate risks and ensure the safe use of 2-ton overhead hoists. Always consult the latest local regulations and manufacturer instructions for comprehensive safety compliance.

List Reference Technical Parameters of “2 ton overhead hoist”

A 2-ton overhead hoist is a crucial piece of industrial equipment used for lifting and moving heavy loads. Below are the key reference technical parameters for such a hoist:

1. Load Capacity: 2 tons (4,000 lbs or 1,814 kg).

2. Lifting Height: Varies by model, typically ranging from 10 to 30 feet (3 to 9 meters).

3. Lifting Speed: Generally between 5 to 20 feet per minute (1.5 to 6 meters per minute), adjustable in some models.

4. Power Source: Electric (common voltages include 230V, 460V, 575V) or pneumatic options.

5. Motor Power: Generally, 1-3 horsepower (hp) depending on the design.

6. Control Type: Pendant control, wireless remote control, or manual pull chain.

7. Duty Cycle: Class C (Moderate), Class D (Heavy Duty), or Class E (Severe Duty) based on intended industrial use.

8. Chain or Wire Rope: Chain hoists are more common for this capacity, but wire rope hoists are available.

9. Hook Opening: Typically around 1.25 to 2 inches (3 to 5 cm).

10. Safety Features: Overload protection, emergency stop button, upper and lower limit switches.

11. Hoist Trolley: Manual push/pull, hand-geared, or motorized, suitable for the beam size.

12. Weight: The hoist unit itself may range between 100 to 300 lbs (45 to 136 kg).

13. Standards Compliance: Must meet OSHA, ANSI, ASME (B30.16 or B30.22) standards.

14. Frame Construction: Durable materials such as steel or alloy for longevity and safety.

15. Environmental Protection: IP54 to IP65 rated enclosures for dust and water resistance.

These parameters ensure the hoist operates efficiently, safely, and meets the demands of various industrial applications.

List Product features of “2 ton overhead hoist”

Certainly! Here are the key product features of a 2-ton overhead hoist:

1. Load Capacity: Capable of lifting and moving loads up to 2 tons (4,000 lbs), making it suitable for heavy-duty industrial applications.

2. Construction: Often constructed from high-strength steel or other durable materials to ensure longevity and withstand rigorous use.

3. Type of Hoist:

– Electric: Powered by an electric motor for efficient, automated operations.

– Manual: Operated manually through a chain mechanism for lower operational costs and simpler maintenance.

– Pneumatic: Utilizes compressed air for operations, ideal for environments where electrical sparks pose a risk.

4. Lifting Mechanism: Typically includes a robust gearbox and motor system (for electric models) or a sturdy hand chain (for manual models).

5. Control Options:

– Pendant Control: Wired remote control for precise manipulation of lifting, lowering, and positioning.

– Wireless Remote: Provides greater freedom of movement and safer operation from a distance.

6. Lift Height: Varies based on the model, but often provides substantial lift heights ranging from 10 to 30 feet or more, accommodating different workspace requirements.

7. Hoisting Speed: Variable speed settings available in electric models for greater control over operations.

8. Safety Features:

– Automatic Braking: Ensures the hoist stops immediately when controls are released.

– Overload Protection: Prevents damage by not allowing lifting beyond the rated capacity.

– Emergency Stop: Immediate cessation of operation for emergency situations.

9. Swiveling Hooks: 360-degree rotating hooks with safety latches for secure and versatile load handling.

10. Ease of Installation: Designed to be mounted on cranes, gantries, or overhead beams with relative ease.

11. Noise Reduction: Some models include features to minimize operational noise for more comfortable working conditions.

12. Maintenance: Engineered for minimal maintenance with accessible components for easy repairs and inspections.

13. Compliance: Meets relevant industry standards and regulations (e.g., OSHA, ANSI, CE), ensuring safety and reliability.

14. Weather Resistance: Some models are designed for outdoor use with weather-resistant finishes and components.

These feature sets make the 2-ton overhead hoist a versatile and essential tool for material handling in various industries, including manufacturing, construction, warehousing, and logistics.

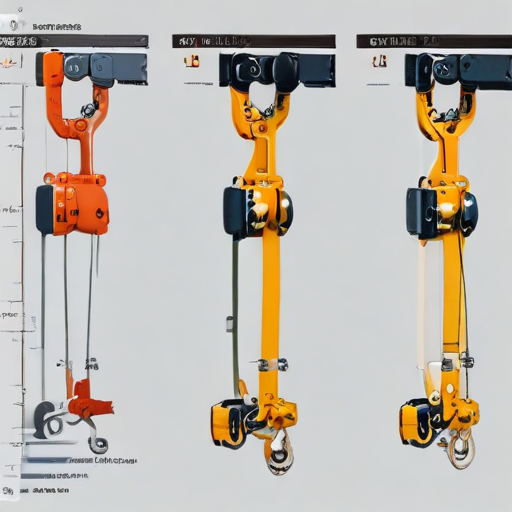

List Various Types of “2 ton overhead hoist”

Certainly! Here are the common types of 2-ton overhead hoists:

1. Electric Chain Hoist

– Single Speed Electric Chain Hoist: Operates at one fixed speed, ideal for repetitive applications.

– Dual Speed Electric Chain Hoist: Offers two-speed options for precise load handling and positioning.

2. Electric Wire Rope Hoist

– Single Speed Electric Wire Rope Hoist: Provides reliable lifting at a consistent speed, suitable for general use.

– Variable Speed Electric Wire Rope Hoist: Allows adjustable speeds for more control over lifting and lowering.

3. Manual Chain Hoist

– Operated by hand chains, suitable for light-duty tasks where power is unavailable or impractical.

4. Lever Hoist

– Also known as a come-along, manually operated by a lever for both lifting and pulling tasks.

5. Pneumatic (Air) Hoist

– Chain Type Pneumatic Hoist: Uses compressed air, ideal for explosive or hazardous environments.

– Wire Rope Pneumatic Hoist: Provides high lifting speeds and precision in controlling the load.

6. Hydraulic Hoist

– Utilizes hydraulic pressure, often for heavy-duty and precise lifting applications.

7. Low Headroom Hoist

– Designed for areas with limited vertical space, maximizing the lifting height.

Each type of 2-ton overhead hoist serves specific operational needs, ranging from basic manual handling to sophisticated electric and pneumatic systems for industrial tasks. When selecting a hoist, consider factors like the environment, lifting frequency, precision, and available power sources.

List Application of “2 ton overhead hoist”

A 2-ton overhead hoist is a versatile piece of equipment used across various industries for lifting and moving heavy loads. Here are some primary applications:

1. Manufacturing: In manufacturing plants, a 2-ton overhead hoist is used to lift and transport raw materials and finished products along the production line, enhancing efficiency and safety.

2. Construction: On construction sites, it assists in moving heavy building materials, such as steel beams, concrete blocks, and equipment, thus reducing manual labor and risks.

3. Warehousing and Logistics: In warehouses, the hoist aids in stacking and retrieving heavy items from high shelves, optimizing storage and retrieval processes.

4. Automotive Industry: Used to lift engines, transmissions, and other heavy components during assembly or maintenance, ensuring precision and safety in handling large parts.

5. Mining: In mines, a hoist helps in the transportation of extracted minerals and heavy machinery, playing a crucial role in operations within confined and rugged spaces.

6. Shipyards: The hoist is integral to shipbuilding and repair activities, enabling the lifting of heavy parts such as engines, propellers, and sections of hulls.

7. Aviation Maintenance: Used for lifting aircraft parts for repair and maintenance, supporting the safe and efficient handling of large, intricate components.

8. Foundries: In metal casting operations, it assists in handling molds and heavy castings, improving workflow and reducing the physical strain on workers.

9. Power Plants: Utilized for maintenance and repair of heavy equipment, including generators and turbines, ensuring uninterrupted power generation.

10. Utilities and Infrastructure: Employed in the maintenance of heavy utility components like transformers, poles, and substation gear.

These are just some examples showcasing the indispensability of a 2-ton overhead hoist in improving operational efficiency, safety, and productivity across various sectors.

List Buyer Types of “2 ton overhead hoist”

Buyer types for a “2-ton overhead hoist” can be categorized based on industry, application, and scale of operation. Below is a concise summary:

1. Manufacturing Plants

– Automotive Industry: Uses hoists for lifting vehicle parts and engines.

– Metal Fabrication: Essential for moving heavy steel components and assemblies.

2. Construction Companies

– Commercial Construction: Utilizes hoists for lifting construction materials and equipment.

– Infrastructure Projects: Needed for handling heavy loads in bridge and road construction.

3. Warehousing and Logistics

– Distribution Centers: Employ hoists for moving goods and inventory efficiently.

– Freight Forwarding: Uses hoists for loading and unloading heavy shipments.

4. Utility Services

– Electricity Distribution: For lifting transformers and electrical infrastructure.

– Water Treatment Plants: Uses hoists for moving heavy pumps and treatment machinery.

5. Mining and Extraction

– Mining Operations: Critical for lifting ore, equipment, and safety apparatus.

– Oil and Gas Sector: Employed for lifting heavy drilling equipment and machinery.

6. Marine Sector

– Shipbuilding and Repair: Uses hoists for assembling ship components and repairs.

– Port Operations: Moves heavy cargo and containers on docksides.

7. Maintenance and Repair Services

– Industrial Repair Services: Necessary for maintaining and repairing heavy machinery.

– Facility Management: Utilized for lifting HVAC units and other large maintenance items.

8. Agriculture and Forestry

– Farm Equipment Service: Used for handling large farm machinery and tools.

– Timber Processing: Lifts heavy timber in sawmills and processing plants.

By understanding these buyer types, suppliers can better tailor their marketing, sales, and service strategies to meet the specific needs of each industry segment.

List “2 ton overhead hoist” Project Types for Different Industries

A 2-ton overhead hoist finds applications across various industries due to its versatility and capacity for lifting heavy loads. Here’s a brief overview of different project types in distinct sectors:

1. Manufacturing:

– Assembly Lines: Used for lifting and positioning heavy components.

– Fabrication Shops: Essential for handling large metal sheets and parts.

2. Construction:

– Building Sites: Moving heavy materials like steel beams and concrete panels.

– Bridge Construction: Transporting and placing large structural elements.

3. Warehousing and Logistics:

– Inventory Management: Lifting heavy crates and pallets.

– Loading and Unloading: Aiding in the transfer of cargo to and from vehicles.

4. Automotive:

– Garage Workshops: Hoisting engines and other car parts for maintenance.

– Production Lines: Component placement and adjustment.

5. Aerospace:

– Aircraft Maintenance: Handling engines and large aircraft parts.

– Component Assembly: Assembling and positioning aircraft components.

6. Energy:

– Power Plants: Maintenance and installation of heavy machinery and components.

– Wind Turbines: Lifting turbine components during installation or repair.

7. Mining:

– Material Handling: Moving ore, equipment, and supplies.

– Equipment Maintenance: Aiding in the heavy-lift requirements of machinery upkeep.

8. Marine:

– Shipbuilding: Positioning large sections of hulls and superstructures.

– Port Operations: Loading and unloading heavy cargo.

9. Railway:

– Maintenance Depots: Handling heavy parts of trains for repair and maintenance.

– Construction Sites: Lifting track sections and support structures.

10. Utilities:

– Water Treatment: Lifting pumps and other heavy machinery.

– Telecommunications: Positioning heavy communication equipment in towers.

Each industry leverages the 2-ton overhead hoist’s reliability and efficiency to enhance productivity and safety in handling substantial loads.

2 ton overhead hoist Accessories Upgrades and Custom Manufacturing Options

A 2-ton overhead hoist is versatile and essential for material handling in various industries. To enhance its functionality, several accessories, upgrades, and custom manufacturing options are available:

Accessories

1. Trolleys: Motorized or manual trolleys help in smooth lateral movement along the beam.

2. Remote Controls: Wireless remote controls offer safe and convenient hoist operation from a distance.

3. Load Indicators: Digital or analog load indicators provide real-time weight measurements to prevent overloading.

4. Limit Switches: These safety devices automatically stop the hoist at pre-set points to prevent over-travel.

5. Chain Containers: Keep the excess chain organized and reduce wear and tear.

6. Hooks and Slings: Various attachments like C-hooks, basket slings, and sheet handlers for specific lifting needs.

Upgrades

1. Speed Control: Variable frequency drives (VFD) for precise speed control of lifting and lowering operations.

2. Enhanced Motors: High-efficiency motors reduce energy consumption and increase durability.

3. Weatherproofing: For outdoor use, adding weatherproofing and rust-resistant materials improves longevity.

4. Noise Reduction: Quieter operation through installation of noise-dampening pads and other technologies.

Custom Manufacturing Options

1. Tailored Lifting Capacity: Adjustments can be made to handle specific weight capacities beyond the standard 2-ton limit.

2. Specialized Hoists: Explosion-proof hoists for hazardous areas or corrosion-resistant units for marine environments.

3. Custom Dimensions: Custom hook paths, beam sizes, and spans to fit unique spatial requirements.

4. Advanced Safety Features: Integration of advanced safety protocols such as redundant braking systems and overload protection.

By incorporating these accessories, upgrades, and custom options, a 2-ton overhead hoist can be optimized to perfectly fit specific operational needs, enhancing both functionality and safety.

List Quality Control and The Manufacturing Process of “2 ton overhead hoist”

Quality Control and Manufacturing Process of a 2 Ton Overhead Hoist

Quality Control:

1. Material Inspection: Raw materials, such as high-strength steel, undergo rigorous testing for tensile strength, hardness, and chemical composition.

2. Supplier Quality Management: Approved vendors provide materials that meet specific standards. Regular audits and quality checks ensure consistency.

3. In-Process Checks: Continuous monitoring during machining, welding, and assembly stages with calibrated tools to maintain dimensional accuracy and alignment.

4. Non-Destructive Testing (NDT): Techniques like ultrasonic testing and magnetic particle inspection verify the integrity of critical components without causing damage.

5. Load Testing: Each hoist is subjected to dynamic and static load tests exceeding the rated capacity to ensure durability and safety.

6. Functional Testing: Full operational checks, including lifting, lowering, and braking mechanisms, are performed to verify functionality and performance.

7. Compliance Certification: Hoists are certified to comply with standards like ANSI/ASME, ensuring they meet industry safety and performance criteria.

8. Final Inspection: A thorough final inspection encompassing visual, dimensional, and operational checks before packaging and dispatch.

Manufacturing Process:

1. Design and Engineering: CAD software is used to design the hoist, followed by simulations and modeling to optimize structure and performance.

2. Cutting and Machining: CNC machines precisely cut and shape steel components, ensuring high accuracy and repeatability.

3. Welding and Fabrication: Skilled welders join components using techniques like MIG/TIG welding, ensuring strong and durable joints.

4. Assembly: Major components such as the gear train, motor, drum, and hook are assembled using jigs and fixtures to maintain alignment.

5. Surface Treatment: Components undergo processes like shot blasting, priming, and powder coating to enhance corrosion resistance and surface finish.

6. Gearbox Assembly: Gears and bearings are assembled in a clean environment, ensuring smooth operation and longevity.

7. Motor Installation: Electrical motors and control systems are installed and wired, followed by functional tests.

8. Quality Assurance: Comprehensive testing, including operational and safety checks, is performed to ensure compliance with specifications.

9. Packaging and Shipping: Finished hoists are securely packaged with protective materials and labeled to ensure safe transportation.

This process ensures that each 2-ton overhead hoist produced is reliable, durable, and meets stringent quality standards.

How to use “2 ton overhead hoist”

Using a 2-ton overhead hoist involves several critical steps to ensure safety and efficiency. Here’s a concise guide:

Preparation:

1. Read the Manufacturer’s Manual: Familiarize yourself with the specific model’s instructions.

2. Inspect the Hoist: Check for any visible damage or wear.

3. Proper Training: Ensure operators are trained and qualified.

4. Clear the Area: Remove any obstacles and ensure the path is clear.

5. Check the Load: Verify the weight does not exceed 2 tons.

Operating the Hoist:

1. Hooking the Load:

– Attach the hoist hook securely to the load.

– Use appropriate slings or lifting devices.

– Ensure the hook’s latch is closed and locked.

2. Lifting the Load:

– Stand clear and ensure others are at a safe distance.

– Use the control pendant or remote to slowly lift the load.

– Pause after lifting a few inches to check balance and stability.

– Continue lifting smoothly at a controlled speed.

3. Moving the Load:

– Use the trolley system to move the hoist along the beam.

– Move the load horizontally to the desired location.

– Avoid sudden movements to prevent swinging.

4. Lowering the Load:

– Gradually lower the load using the controls.

– Ensure the area below is clear.

– Position the load precisely.

After Use:

1. Unload the Hoist: Remove slings or lifting devices.

2. Inspect the Equipment: Check for any damage or unusual wear after use.

3. Proper Storage: Safely store the hoist and associated equipment.

Safety Precautions:

– Never exceed the rated capacity.

– Regularly inspect the hoist.

– Follow all safety guidelines provided by the manufacturer.

By following these steps and prioritizing safety, you can effectively use a 2-ton overhead hoist for various lifting tasks.

“2 ton overhead hoist” Comparative Analysis

A 2-ton overhead hoist is a lifting device commonly employed in workshops, factories, and construction sites to elevate heavy loads. When comparing different models, several critical factors must be evaluated to determine the best option for a specific application.

1. Type: Overhead hoists come in various types, such as electric, pneumatic, and manual. Electric hoists generally provide higher lifting speeds and ease of use, suitable for frequent and heavy-duty applications. Pneumatic hoists are ideal for environments where electrical sparks could pose a risk, like in explosive atmospheres. Manual hoists are more cost-effective and appropriate for occasional or light-duty tasks.

2. Construction and Durability: Look for hoists constructed from high-grade materials like steel or alloy for longevity and reliability. Corrosion-resistant coatings and robust components are essential for enduring harsh conditions.

3. Lifting Speed and Height: Electric models typically offer variable lifting speeds, enhancing operational efficiency. The lifting height, or the maximum vertical distance the hoist can lift a load, should align with the requirements of the workspace.

4. Safety Features: Key safety features such as overload protection, emergency stop mechanisms, and braking systems are essential to prevent accidents and ensure safe operation.

5. Ease of Maintenance and Use: Models designed for straightforward maintenance with easily accessible parts reduce downtime. Intuitive controls and ergonomic designs can improve user experience.

6. Cost and Brand Reputation: Price varies widely depending on the hoist type and features. Established brands often offer better reliability, customer support, and warranties.

7. Customization and Accessories: Some hoists can be customized with additional accessories like remote controls, specialized hooks, and trolleys to better fit specific needs.

In conclusion, the choice of a 2-ton overhead hoist hinges on understanding the specific requirements of the task, emphasizing safety, performance, and durability.

“2 ton overhead hoist” Warranty and Support

When investing in a 2-ton overhead hoist, understanding the warranty and support offered is crucial for ensuring long-term reliability and peace of mind. Most reputable manufacturers provide a comprehensive warranty, often covering a period ranging from one to three years. This warranty typically includes coverage for any defects in materials and workmanship, ensuring that any issues arising within the specified period can be addressed without incurring extra costs.

It’s essential to review the warranty terms carefully. Pay attention to what is and isn’t covered. For example, standard wear and tear or damage due to improper use might not be included. Some manufacturers may also offer extended warranty options for an additional fee, providing further protection beyond the initial period.

Support is another critical aspect to consider. Leading manufacturers offer robust customer support, including technical assistance, troubleshooting, and maintenance guidance. Support services often include a dedicated helpline, email support, and sometimes live chat options. Additionally, many suppliers provide detailed user manuals and online resources, such as video tutorials and FAQs, to assist with installation and operation.

For specific concerns or complex issues, having access to a network of authorized service centers or technicians can be invaluable. This network ensures that any repairs or maintenance tasks are performed by trained professionals using genuine parts, thereby maximizing the lifespan and efficiency of your hoist.

In summary, a solid warranty and robust support system are vital when selecting a 2-ton overhead hoist. They not only safeguard your investment but also provide the assurance that help is readily available should any issues arise. Ensure to thoroughly review all warranty terms and seek out manufacturers known for their exceptional customer support.

List “2 ton overhead hoist” FAQ

2 Ton Overhead Hoist FAQ

1. What is a 2-ton overhead hoist?

A 2-ton overhead hoist is a mechanical device designed to lift and move loads weighing up to 2 tons (4,000 lbs) across a workspace. They are commonly used in industries such as construction, manufacturing, and warehousing.

2. What types of 2-ton overhead hoists are available?

There are several types, including electric chain hoists, manual chain hoists, and electric wire rope hoists. The selection depends on the application, frequency of use, and specific operational needs.

3. How is the hoist operated?

Operation varies by type:

– Electric Chain or Wire Rope Hoist: Typically controlled via a pendant control or a wireless remote.

– Manual Chain Hoist: Operated by pulling a hand chain that moves the load chain.

4. What are the key components of an overhead hoist?

Main components include the lifting mechanism (chain or wire rope), motor (for electric hoists), brakes, a hook or sling for securing the load, and the overhead track or crane system.

5. How do I install a 2-ton overhead hoist?

Installation should be completed by a qualified professional to ensure safety and compliance with local regulations. Key steps include securing the hoist to an appropriate support structure and conducting thorough safety tests.

6. What maintenance does a 2-ton hoist require?

Regular maintenance is crucial for safety and longevity. This includes inspecting chains/ropes, checking for wear and tear, lubricating moving parts, and ensuring the braking system is functioning correctly.

7. What are the safety considerations?

– Never exceed the hoist’s load capacity.

– Regularly inspect the equipment for any signs of damage.

– Ensure operators are properly trained.

– Implement a proper locking and tagging system during maintenance.

8. Can a 2-ton hoist be used outdoors?

Yes, but ensure that it is rated for outdoor use. Weather-resistant models are available, and special care should be taken to protect the hoist from extreme environmental conditions.

9. What certifications should a 2-ton hoist have?

Look for hoists that comply with relevant industry standards such as ANSI, ASME, or OSHA to ensure safety and reliability.

By addressing these common questions, users can better understand and safely utilize a 2-ton overhead hoist in their operations.

Top 10 FAQ with answer about 2 ton overhead hoist for Buyer Sourcing from China

Certainly! Below are the top 10 frequently asked questions (FAQ) about sourcing a 2-ton overhead hoist from China, along with concise answers:

1. What is the lead time for a 2-ton overhead hoist from China?

– Generally, the lead time ranges from 4 to 8 weeks, depending on manufacturing schedules and custom requirements.

2. What certifications should I look for to ensure quality?

– Look for certifications like ISO 9001, CE, and TUV. These indicate the product meets international quality and safety standards.

3. Can I customize the hoist to meet specific requirements?

– Yes, many Chinese manufacturers offer customization options, including changes in lifting height, speed, and control systems.

4. What are the key components to check for quality in a 2-ton overhead hoist?

– Inspect the motor, brakes, chain or wire rope, gearbox, and control system for durability, reliability, and compliance with international standards.

5. Are Chinese manufacturers reliable when it comes to after-sales service?

– This varies; research the company’s reputation, read reviews, and ensure they offer parts and service support.

6. How can I verify the legitimacy of the supplier?

– Check for business licenses, ask for past customer references, and verify through third-party verification services like Alibaba’s Trade Assurance or Global Sources.

7. What are the shipping options and costs?

– Shipping options include air freight, sea freight, and express courier. Costs depend on the shipping method and distance; sea freight is usually the most cost-effective for heavy equipment.

8. How is payment usually handled?

– Common payment terms include T/T (Telegraphic Transfer), L/C (Letter of Credit), or through secure online payment platforms. Initial deposits followed by balance payments upon delivery are typical.

9. Are spare parts readily available?

– Confirm with the manufacturer that spare parts are available and ask for a list of critical parts you might need to stock.

10. What warranty terms are usually offered?

– Warranties vary but typically range from 12 to 24 months. Make sure to get detailed warranty terms in writing, covering both parts and labor.

By addressing these FAQs, buyers can better navigate the process of sourcing a reliable 2-ton overhead hoist from China, ensuring quality and service.