20 ton overhead crane Safety Certifications

Operating a 20-ton overhead crane necessitates complying with rigorous safety standards and obtaining relevant certifications to ensure safe and efficient operation. Below are the key safety certifications and guidelines:

OSHA (Occupational Safety and Health Administration)

– OSHA 1910.179: This standard addresses the safety requirements for overhead and gantry cranes. It includes guidelines for the design, inspection, testing, maintenance, and operation of the crane.

– Inspection Requirements: Daily and periodic inspections are mandated to identify any potential issues and ensure the crane is functioning correctly.

CMAA (Crane Manufacturers Association of America)

– CMAA 70: This specification outlines the design specifications for electric overhead traveling cranes. It ensures the crane is built to industry standards for performance and safety.

ASME (American Society of Mechanical Engineers)

– ASME B30.2: This standard provides comprehensive guidelines for the construction, installation, operation, inspection, and maintenance of overhead and gantry cranes.

– Operator Certification: Ensures that crane operators possess the necessary skills and knowledge. Certification from recognized bodies such as NCCCO (National Commission for the Certification of Crane Operators) is often required.

ISO Standards

– ISO 9001: Ensures that the manufacturing and quality assurance processes conform to international standards, providing an additional layer of safety and reliability.

– ISO 9927-1: Covers the general procedures and requirements for the inspection, testing, and maintenance of cranes.

Additional Considerations

– Maintenance Logs: Keeping detailed logs of all inspections, maintenance, and repairs is critical.

– Load Testing: Regular load testing to ensure the crane can safely handle its rated capacity.

– Emergency Procedures: Implementing and training staff on emergency procedures in case of crane failure or other hazards.

In summary, adherence to OSHA, CMAA, ASME, and ISO standards, alongside regular inspections, proper maintenance, and operator certification, forms the cornerstone of safety for 20-ton overhead cranes.

List Reference Technical Parameters of “20 ton overhead crane”

When discussing a 20-ton overhead crane, several technical parameters are crucial for its selection and operation. Below is a list of key parameters:

1. Load Capacity: The maximum weight the crane can lift, which in this case is 20 tons.

2. Span Length: The horizontal distance between the two rails upon which the crane operates. Typical span lengths range from 10 to 30 meters, but can be customized.

3. Lift Height: The maximum height that the hoist can lift the load, often specific to application requirements. Commonly ranges from 6 to 30 meters.

4. Duty Cycle/Class: Classified according to the frequency of use and the nature of the load. For instance, Class C (Moderate Service), Class D (Heavy Service), etc.

5. Hoist Type: Options include wire rope hoists for heavy-duty operations and chain hoists for lighter applications.

6. Speed Parameters:

– Hoist Speed: Speed at which the load is lifted or lowered.

– Trolley Speed: Speed at which the trolley moves horizontally along the bridge.

– Bridge Speed: Speed at which the entire crane moves on the runway.

7. Power Supply: Electrical requirements can vary but common voltages include 220V, 380V, or 440V, with 3-phase AC power.

8. Control System: Modern cranes typically have options for pendant control, remote control, or a cab control for operator convenience and safety.

9. End Trucks: The assemblies that support the bridge, containing wheels that run on the runway rails.

10. Safety Features: Essential features include overload protection, emergency stop, limit switches for both hoist and traverse motions, and anti-collision systems.

11. Environmental Conditions: Rated for indoor or outdoor use, which affects material choice for corrosion resistance, weatherproofing, and operational temperature range.

These parameters collectively define the operational capabilities and limitations of a 20-ton overhead crane, ensuring it meets specific application needs and safety requirements.

List Product features of “20 ton overhead crane”

Certainly! Here’s a concise list of product features for a “20 ton overhead crane”:

1. Load Capacity: Engineered to lift and maneuver loads up to 20 tons (40,000 pounds), ideal for heavy-duty industrial applications.

2. Span: Available in varying spans to suit different facility widths, typically ranging from 10 to 100 feet or more, ensuring flexibility in installation.

3. Lift Height: Customizable lifting height options, with standard configurations offering lifts from 20 to 50 feet, allowing for versatile usage in different environments.

4. Crane Type: Offered in both single-girder and double-girder designs to meet specific structural and operational needs.

5. Hook Coverage: Provides extensive hook coverage and optimal use of working space for efficient material handling.

6. Trolley System: Equipped with motorized trolleys for smooth, precise, and efficient horizontal movement across the crane’s span.

7. Controls: Features advanced control systems including pendant push-button stations, wireless remote control, and optional cab control for enhanced operator convenience and safety.

8. Variable Speed: Incorporates variable frequency drives (VFD) for controlled acceleration and deceleration, ensuring smooth start and stop operations and reducing wear on mechanical components.

9. Safety Systems: Fitted with comprehensive safety features such as overload protection, end stop buffers, limit switches, and emergency stop functions to minimize risk and enhance operational safety.

10. Durability: Constructed with high-strength steel and quality components to ensure long-term durability and reliability, even in demanding industrial environments.

11. Maintenance Access: Easy access to key components for routine inspections and maintenance, facilitating longer operational life and reduced downtime.

12. Customization: Available with customizable options such as different hoist configurations, special environmental coatings, or custom automation solutions to meet specific application requirements.

13. Compliance: Designed and manufactured to meet or exceed industry standards and safety regulations, ensuring legal compliance and safe operation.

14. Energy Efficiency: Modern designs incorporate energy-efficient motors and systems to help reduce overall operational costs and environmental impact.

These features collectively enable a “20 ton overhead crane” to enhance productivity, safety, and efficiency in various industrial and construction settings.

List Various Types of “20 ton overhead crane”

A 20-ton overhead crane is a versatile piece of equipment used in various industries for heavy lifting and material handling tasks. There are several types, each designed to suit specific applications and environments:

1. Single Girder Overhead Crane:

– Characteristics: Features one main girder with a hoist traveling on the lower flange.

– Usage: Ideal for light to medium-duty applications with a moderate span and height.

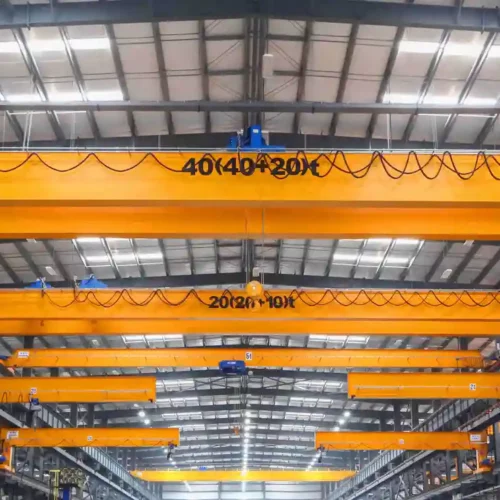

2. Double Girder Overhead Crane:

– Characteristics: Has two girders, allowing for a higher lifting capacity, increased stability, and extended span.

– Usage: Suitable for heavy-duty tasks and larger industrial facilities requiring frequent, heavy lifting.

3. Top Running Overhead Crane:

– Characteristics: The crane runs on rails mounted on the top of the runway beams, maximizing hook height and load capacity.

– Usage: Common in manufacturing facilities, warehouses, and assembly lines needing high clearance.

4. Under Running (Underslung) Overhead Crane:

– Characteristics: Runs on the bottom flanges of the runway beams, often allowing for more flexible use in tighter spaces.

– Usage: Suitable for factories with lower headroom where maximizing floor space is crucial.

5. Explosion-Proof Overhead Crane:

– Characteristics: Built with explosion-proof elements to safely operate in hazardous environments.

– Usage: Utilized in industries like chemical, petroleum, and mining, where explosive gases or dust are present.

6. Magnetic Overhead Crane:

– Characteristics: Equipped with a magnetic lifter for handling metal materials efficiently.

– Usage: Ideal for steel mills, scrap yards, and other sectors handling ferrous metal products.

7. Gantry Overhead Crane:

– Characteristics: Supported by legs that move on wheels or tracks, often used outdoors.

– Usage: Often found in shipyards, construction sites, and large-scale manufacturing plants.

Each type of 20-ton overhead crane offers unique advantages tailored to specific operational needs, ensuring efficient and safe material handling across various sectors.

List Application of “20 ton overhead crane”

A 20-ton overhead crane is engineered to lift and move heavy loads with precision and efficiency in various industrial settings. Here are some key applications:

1. Manufacturing:

– Automotive: Transporting car frames, engines, and other large components.

– Heavy Machinery: Handling parts and assemblies for large machines.

2. Warehousing and Logistics:

– Storage: Managing inventory by moving large, heavy-stock items.

– Loading and Unloading: Streamlining the process of transferring cargo to and from transport vehicles.

3. Construction:

– Building Materials: Lifting steel beams, concrete slabs, and other construction elements.

– Prefabricated Sections: Positioning large prefabricated sections into place.

4. Shipyards:

– Shipbuilding: Moving heavy ship components and equipment.

– Maintenance: Supporting repair and upgrading tasks by lifting large ship parts.

5. Steel Mills and Foundries:

– Metalwork: Lifting molten metal containers and transporting heavy finished products.

– Casting: Assisting in the casting process by moving molds and casts.

6. Power Plants:

– Turbine Maintenance: Handling large turbines, generators, and other critical equipment during maintenance.

– Fuel Transport: Moving heavy fuel containers and components.

7. Mining:

– Equipment Transport: Relocating earth-moving equipment and transporting mined materials.

– Ore Handling: Lifting heavy loads of ore and other mining outputs.

8. Aerospace:

– Aircraft Assembly: Assisting in the assembly of large aircraft parts.

– Component Manufacturing: Lifting and moving heavy aerospace components during manufacturing.

9. Railway:

– Carriage and Locomotive Maintenance: Lifting railcars and locomotives for inspection and repair.

10. Chemical Plants:

– Reactor Maintenance: Moving heavy reactors and other large pieces of equipment.

– Material Handling: Transporting bulk chemical containers.

In each of these applications, 20-ton overhead cranes improve efficiency, safety, and workflow by enabling the precise and controlled movement of heavy loads.

List Buyer Types of “20 ton overhead crane”

Buyers of 20-ton overhead cranes typically span various industries and sectors due to the equipment’s versatility and capacity for heavy lifting. Here are the primary types of buyers:

1. Manufacturing Plants: Factories that produce heavy machinery, automotive parts, and other goods frequently need overhead cranes to move heavy materials across the production floor.

2. Warehouses: Large storage facilities utilize overhead cranes to handle heavy pallets and large items, enhancing operational efficiency and safety.

3. Construction Companies: For lifting and placing heavy materials such as steel beams, pre-cast concrete, and other large construction elements.

4. Steel Mills: The steel industry often requires robust and reliable overhead cranes to handle raw materials, molten metal, and finished products.

5. Shipyards: Building and repairing ships involve lifting heavy components like ship sections, engines, and large tools, making overhead cranes essential.

6. Mining Operations: These buyers use cranes to move heavy mining equipment, containers, and extracted materials.

7. Railways: For lifting and positioning heavy rail components, cars, and maintenance materials.

8. Military and Defense Facilities: Utilized for handling heavy-duty machinery, weapons systems, and other large materials in a secure and controlled environment.

9. Power Plants: Facilities that generate power, whether nuclear, hydroelectric, or fossil fuel-based, often require overhead cranes to maintain and replace heavy equipment.

10. Logistics and Freight Companies: For loading and unloading heavy goods in freight stations and distribution centers.

11. Equipment Rental Companies: They purchase cranes to rent them out to various businesses on short-term or long-term bases.

12. Recycling Plants: These plants use overhead cranes to move scrap materials and heavy machinery.

These diverse buyers all seek the capabilities of a 20-ton overhead crane to improve efficiency, safety, and productivity in handling heavy materials and equipment.

List “20 ton overhead crane” Project Types for Different Industries

Sure, here’s a concise list of project types involving 20-ton overhead cranes across various industries:

1. Manufacturing: Facilitates the handling of heavy machinery, raw materials, and finished products.

2. Automotive: Assists in assembling large components, transporting heavy parts, and maintaining equipment.

3. Construction: Useful for lifting building materials, structural steel, and prefabricated components.

4. Steel Mills: Critical in handling molten metal, slabs, coils, and other heavy steel products.

5. Shipbuilding: Supports the construction and repair of ships by lifting heavy sections and components.

6. Aerospace: Employed in the assembly and maintenance of aircraft components and engines.

7. Mining: Lifts heavy equipment and materials in mining operations and processing plants.

8. Energy: Critical for handling heavy components in power generation, including turbines and transformers.

9. Warehousing: Streamlines the movement of heavy inventory and bulk materials.

10. Railway: Utilized for lifting and assembling railway components and maintaining large equipment.

11. Pulp and Paper: Assists in moving heavy rolls, machinery, and finished paper products.

12. Chemical and Petrochemical: Handles heavy reactors, vessels, and other large equipment safely.

13. Maritime: Facilitates the loading and unloading of shipping containers and bulk cargo.

14. Food and Beverage: Aids in the transport of large vats, storage tanks, and heavy processing equipment.

15. Utility Services: Used in maintenance and installation of heavy-scale infrastructure components.

16. Foundries: Moves heavy molds, castings, and equipment essential for production.

17. Plastic Injection Molding: Assists in the handling of large molds and heavy plastic components.

18. Recycling: Manages large bundles of recyclable materials and heavy processing machinery.

19. Lumber and Woodworking: Lifts heavy logs, beams, and processed wood products.

20. Automation and Robotic Production: Supports the installation and maintenance of large robotic systems and automation machinery.

These cranes are crucial for enhancing efficiency, productivity, and safety in various heavy lifting and material handling tasks.

20 ton overhead crane Accessories Upgrades and Custom Manufacturing Options

Upgrading a 20-ton overhead crane can significantly enhance its performance, safety, and longevity. Here are some key accessories and custom manufacturing options:

1. Variable Frequency Drives (VFDs): Enhance control over speed and movement, reducing mechanical stress and improving load handling precision.

2. Remote Control Systems: Increase operational safety and flexibility by enabling crane operation from a distance, reducing the need for direct interaction with potentially hazardous areas.

3. Load Indicators and Weighing Systems: Provide real-time monitoring of load weights to prevent overloading and ensure compliance with safety regulations.

4. Anti-Sway Technology: Reduces load swing, enhancing both safety and efficiency during material handling tasks.

5. Advanced Hoisting Mechanisms: Consider upgrading to more efficient or robust hoisting devices that can offer better performance and durability, such as electric wire rope hoists or chain hoists.

6. Custom Lifting Attachments: Tailor-fit your crane for specific tasks by incorporating specialized grips, magnets, or vacuum lifters to handle a variety of materials more effectively.

7. Collision Avoidance Systems: Sensor-based systems that help prevent accidents by detecting obstacles and automatically stopping the crane.

8. End Truck Upgrades: Enhanced end trucks with better bearings and wheels can improve the lifespan and reliability of the crane operation.

9. Automated Positioning Systems: Implementing GPS or laser-guided systems can increase the accuracy and efficiency of load placement.

10. Enhanced Safety Features: Including emergency stop buttons, limit switches, and robust safety nets can significantly improve operator safety.

11. Custom Painting and Coatings: Protect the crane from environmental wear and corrosion with specialized paints and coatings, ensuring longevity and maintaining structural integrity.

12. Maintenance Platforms: Provide ease of access for regular maintenance and inspections, ensuring that the crane remains in optimal working condition.

Each of these upgrades and customizations can be tailored to meet the specific needs of your operational environment, enhancing the overall efficiency and safety of your 20-ton overhead crane.

List Quality Control and The Manufacturing Process of “20 ton overhead crane”

20 Ton Overhead Crane: Manufacturing Process and Quality Control

Manufacturing Process:

1. Design and Planning:

– Detailed requirements analysis and custom specifications.

– Creation of CAD drawings and engineering blueprints.

– Finite Element Analysis (FEA) for structural integrity.

2. Raw Material Selection:

– High-quality steel procurement.

– Quality certification of materials (e.g., tensile strength, hardness).

3. Fabrication:

– Cutting: CNC machines for precision.

– Welding: Automated and manual welding; compliance with AWS standards.

– Machining: Drilling, milling, and turning to exact dimensions.

4. Assembly:

– Girder assembly: Main and cross-girders alignment.

– End carriages and hoist mechanism integration.

– Electrical system wiring and control panel assembly.

5. Surface Treatment:

– Sandblasting for surface preparation.

– Priming and painting to prevent corrosion.

6. Testing:

– Load testing with calibrated weights.

– Electrical and mechanical function tests.

Quality Control:

1. Material Inspection:

– Verify material properties against specifications.

– Certification from suppliers.

2. Process Monitoring:

– In-process inspections during cutting, welding, and machining.

– Non-destructive testing (NDT) such as ultrasound or X-ray for weld integrity.

3. Dimensional Accuracy:

– Use of laser measurement tools.

– Tolerances checked against design specifications.

4. Load Testing:

– Testing beyond rated capacity (usually 125%) to ensure safety.

– Static and dynamic load tests.

5. Electrical Inspections:

– Continuity tests for wiring.

– Functional tests for controls and emergency stops.

6. Final Inspection:

– Overall structural and operational assessment.

– Compliance with international standards (e.g., ISO, ANSI).

7. Certification and Documentation:

– Detailed quality reports.

– Load test certificates and compliance documentation.

Conclusion:

The manufacturing and quality control of a 20-ton overhead crane involve meticulous planning, rigorous testing, and stringent standards compliance to ensure safety, reliability, and performance.

How to use “20 ton overhead crane”

Operating a 20-ton overhead crane requires careful preparation and adherence to safety guidelines. Here’s a concise step-by-step guide:

1. Pre-Operation Checks:

– Inspection: Examine the crane for any visible damage or wear, including cables, hooks, and controls. Ensure safety latches are functional.

– Documentation: Verify that the crane has passed recent inspections and maintenance checks as per regulations.

2. Preparation:

– Training: Ensure you are trained and authorized to operate the crane.

– Load Assessment: Calculate the load weight to confirm it does not exceed the crane’s 20-ton capacity. Use appropriate rigging equipment.

3. Control Review:

– Remote/Control Panel: Familiarize yourself with the crane’s control system, including emergency stop functions.

– Test Movements: Conduct a test run of hoisting, lowering, and trolley travel without a load to ensure all directions and speeds are functioning correctly.

4. Lifting the Load:

– Rigging: Attach the load securely using suitable slings and hardware. Double-check all connections.

– Clear Area: Ensure the area is free from obstructions and all personnel are at a safe distance.

– Lift Smoothly: Gradually hoist the load, monitoring for any irregular movements. Avoid sudden starts and stops.

5. Moving the Load:

– Controlled Movements: Utilize slow and controlled motions to transport the load. Use the shortest and most direct path.

– Communication: Coordinate with spotters or other workers using clear signals or radios to maintain safety.

6. Placing the Load:

– Lower Carefully: Gradually lower the load to its destination. Ensure it is stable and secure before releasing.

– Disconnect Rigging: Carefully remove rigging equipment once the load is safely positioned.

7. Post-Operation:

– Secure Crane: Position the crane in its designated resting place and power it down.

– Final Inspection: Conduct a brief inspection to ensure the crane is in good condition for the next use.

Always follow your organization’s specific protocols and safety standards.

“20 ton overhead crane” Comparative Analysis

A 20-ton overhead crane is an essential piece of equipment in various industrial settings such as manufacturing, warehousing, construction, and steel production. When conducting a comparative analysis, several key factors need to be considered:

1. Design Type:

– Single Girder vs. Double Girder: Single girder cranes are typically lighter, less expensive, and simpler in design, making them suitable for lighter loads and smaller spaces. Double girder cranes, on the other hand, offer better load capacity, higher lifting heights, and greater stability, making them more suitable for demanding applications.

2. Control Mechanism:

– Manual vs. Automation: Manual cranes require human intervention, which can limit precision and speed. Automated or semi-automated cranes, controlled via remote or via integrated software systems, offer greater accuracy, enhanced efficiency, and safer operations but often come with higher initial costs.

3. Material and Construction:

– Steel vs. Alloy Construction: Standard models usually feature steel construction, which balances cost and durability. However, cranes made with high-strength alloys offer significant performance advantages like enhanced load-bearing capacity and reduced weight, albeit at a higher cost.

4. Operational Cost:

– Initial vs. Long-term: While initial costs are important, operational and maintenance costs over the crane’s lifespan should also be considered. High-quality, durable components might have higher upfront costs but often result in lower maintenance costs and longer service life.

5. Safety Features:

– Modern 20-ton overhead cranes come equipped with advanced safety features like anti-sway mechanisms, overload protection, and emergency stop functions. Comparing the range and sophistication of these features can provide insights into the safety and reliability of different models.

6. Customizability:

– Customizable options such as lifting speeds, energy consumption rates, and specific attachments can add significant value. A flexible, adaptable crane can better meet the unique demands of different operational environments.

In conclusion, selecting a 20-ton overhead crane requires a comprehensive analysis of its design, control mechanisms, materials, costs, safety features, and customizability. Balancing these factors based on the specific needs of the application will help in choosing the most suitable crane.

“20 ton overhead crane” Warranty and Support

When investing in a 20-ton overhead crane, understanding the warranty and support options is crucial to ensure your equipment remains operational and efficient for years to come.

Warranty:

Typically, most reputable manufacturers offer a warranty period ranging from 1 to 3 years. This warranty covers defects in materials and workmanship under normal use. It’s essential to check the specific terms and conditions, as some components like electrical parts or lifting mechanisms might have different coverage periods. Ensure that the warranty includes prompt repair or replacement of defective parts. Regular maintenance performed by certified technicians, as stipulated in the warranty terms, is often required to keep the warranty valid.

Support:

Quality support is vital for minimizing downtime and maintaining productivity. Look for manufacturers or suppliers that provide comprehensive support services. These services should include:

1. 24/7 Customer Service: Ensure there’s around-the-clock availability to address urgent issues.

2. Technical Assistance: Access to expert advice and troubleshooting, either through phone support, online resources, or on-site visits.

3. Spare Parts Availability: Quick access to genuine spare parts is crucial. Some suppliers offer expedited shipping to minimize downtime.

4. Maintenance Plans: Preventive maintenance packages can help extend your crane’s lifespan and improve performance. These plans often include regular inspections, lubrication, and adjustments.

5. Training Programs: Operator and maintenance staff training can significantly reduce the risk of accidents and improve operational efficiency.

Investing a bit of time into understanding these aspects can save significant trouble and expense down the line, ensuring your 20-ton overhead crane remains a reliable asset in your operations.

List “20 ton overhead crane” FAQ

20 Ton Overhead Crane FAQ

1. What is a 20-ton overhead crane?

A 20-ton overhead crane is a heavy-duty lifting device designed to lift and transport loads up to 20 tons across a workspace. It consists of a bridge that moves along runway beams, a hoist, and trolley mechanisms.

2. What types of 20-ton overhead cranes are available?

There are various types, including single-girder, double-girder, top-running, and under-running cranes. Double-girder cranes are commonly used for higher capacities.

3. What kind of controls are available?

Controls can be manual, pendant-operated, wireless remote-operated, or cabin-operated, depending on the application and safety requirements.

4. What applications are ideal for a 20-ton overhead crane?

These cranes are suitable for heavy industrial settings like manufacturing plants, warehouses, foundries, and construction sites requiring frequent lifting of heavy materials.

5. What are the key specifications to consider?

Important specifications include load capacity, span, lifting height, lifting speed, crane speed, and duty cycle/classification.

6. What safety features should a 20-ton overhead crane have?

Essential safety features included are overload protection, emergency stop buttons, anti-collision systems, limit switches, and operator warning systems.

7. What maintenance is required for a 20-ton overhead crane?

Regular inspections and maintenance of mechanical, electrical, and structural components are crucial. This includes checking wire ropes, hooks, brakes, and lubrication of moving parts.

8. How do I choose the right 20-ton overhead crane for my facility?

Consider factors like load requirements, workspace dimensions, the frequency of use, and specific operational needs. Consulting with a reputable crane manufacturer or supplier is advisable.

9. Can a 20-ton overhead crane be customized?

Yes, cranes can be customized to suit specific needs, including special lifting attachments, spans, and advanced control systems.

10. What is the typical lifespan of a 20-ton overhead crane?

With proper maintenance, a high-quality 20-ton overhead crane can last 20-30 years or more, depending on usage and environmental conditions.

11. Do I need special certification to operate a 20-ton overhead crane?

Operators generally require training and certification to ensure safe operation, according to OSHA or local regulatory standards.

This concise FAQ aims to cover essential queries regarding 20-ton overhead cranes within a 300-word limit.

Top 10 FAQ with answer about 20 ton overhead crane for Buyer Sourcing from China

Certainly! Here are the top 10 frequently asked questions (FAQ) about sourcing a 20-ton overhead crane from China with concise answers:

1. What is the lead time for a 20-ton overhead crane?

– Typically, the lead time ranges from 30 to 60 days, depending on the manufacturer and your customized requirements.

2. Are there different types of 20-ton overhead cranes available?

– Yes, there are single girder and double girder designs. Double girder is usually chosen for a 20-ton capacity because of its higher strength and stability.

3. What about the quality and standards of Chinese overhead cranes?

– Reputable Chinese manufacturers comply with international quality standards like ISO, DIN, FEM, and CMAA. Request certifications and quality assurances before purchase.

4. How do you ensure the crane meets safety standards?

– Ensure the crane is equipped with safety features such as overload protection, emergency stop buttons, and limit switches. Verify compliance with CE/CCC safety standards.

5. What is included in the price of the crane?

– Usually, the ex-factory price includes the crane structure, hoist, and standard electrical components. Additional costs may cover shipping, installation, and customization.

6. How is the crane shipped internationally?

– The crane is typically disassembled and packed in containers for sea freight. Ensure the supplier provides a detailed packing list and instructions for reassembly.

7. Is installation support provided?

– Many manufacturers offer installation support either through sending technicians or providing detailed installation guides and remote support.

8. What kind of after-sales service is available?

– Look for manufacturers offering warranties (typically 1-2 years), spare parts availability, and 24/7 technical support.

9. How do we handle maintenance and repairs?

– Obtain a detailed maintenance schedule and recommended spare parts list from the manufacturer. Also, inquire if they offer training sessions for your maintenance team.

10. Can the crane be customized to our specific requirements?

– Yes, most reputable manufacturers offer customization options for boom length, lifting height, speed, and additional features based on your specific needs.

These answers provide a foundational understanding to help you confidently source a 20-ton overhead crane from China.