3 ton gantry crane Safety Certifications

A 3-ton gantry crane is a critical piece of equipment used for lifting heavy loads in various industries. Ensuring safety is paramount, and specific certifications demonstrate compliance with industry standards. Key safety certifications for gantry cranes include:

1. OSHA Compliance: The Occupational Safety and Health Administration (OSHA) sets forth regulations to ensure safe operation. Gantry cranes must comply with OSHA standards, including 1910.179 (Overhead and Gantry Cranes) and General Duty Clause requirements.

2. ASME B30.2 and B30.17: The American Society of Mechanical Engineers (ASME) outlines safety standards for overhead and gantry cranes in its B30.2 and B30.17 sections. These standards cover design, maintenance, inspections, testing, and operator qualifications.

3. CMAA Specifications: The Crane Manufacturers Association of America (CMAA) provides specifications (such as CMAA 70 and 74) for the construction, installation, and performance of cranes, ensuring durability and safety.

4. ISO 9001 Certification: This certification confirms that a manufacturer’s quality management system meets international standards, ensuring consistency in crane manufacturing and adherence to safety protocols.

5. ANSI Codes: The American National Standards Institute (ANSI) also provides guidelines for the safe design and operation of cranes, aligning with other safety standards like those from OSHA and ASME.

6. CE Marking: In Europe, the CE Marking signifies that the crane meets EU safety, health, and environmental protection requirements, adhering to directives such as the Machinery Directive (2006/42/EC).

7. Lifting Equipment Engineers Association (LEEA): Membership in LEEA, and adherence to its Code of Practice, underscores a commitment to lifting equipment safety and professional competence.

Routine inspections, regular maintenance, operator training, and adherence to manufacturer guidelines are crucial for the safe operation of a 3-ton gantry crane. Proper documentation and record-keeping of all safety checks and certifications should be maintained to ensure compliance and enhance workplace safety.

List Reference Technical Parameters of “3 ton gantry crane”

A 3-ton gantry crane is a versatile piece of lifting equipment commonly used in workshops, warehouses, and construction sites. Below are the key technical parameters of such a crane:

1. Load Capacity:

– Rated Load: 3 tons (3000 kg)

2. Span Length:

– Range: Typically between 3 meters to 12 meters, depending on the design and application.

3. Lifting Height:

– Standard Range: 3 meters to 9 meters, customizable based on client requirements.

4. Lifting Speed:

– Generally 0.8m/min to 8m/min, varying based on the specific hoisting mechanism.

5. Trolley Speed:

– Usually around 2m/min to 20m/min, depending on the operational needs.

6. Crane Travel Speed:

– Varies from 3.2m/min to 40m/min, adjustable to fit different operational environments.

7. Power Supply:

– Voltage: Generally 380V/50Hz, but customizable based on regional specifications.

– Phase: Typically 3-phase AC.

8. Control System:

– Options range from pendant control and remote control to cab control.

9. Duty Classification:

– Commonly assigned A3 to A5 per ISO standards, indicating moderate service conditions.

10. Hoist Mechanism:

– Type: Electric hoist, often wire rope or chain hoist.

– Motor: Squirrel-cage induction motors or similar.

11. Materials and Construction:

– Frame: High-quality steel, corrosion-resistant.

– Wheels: Forged steel or cast iron, suitable for specific tracks.

12. Safety Features:

– Overload protection, limit switches, emergency stop, anti-collision devices, and buffer.

13. Environmental Conditions:

– Operating Temperature: Generally -20°C to 40°C.

– Suitable for indoor and outdoor use, with weatherproofing features for outdoor models.

These technical specifications ensure the 3-ton gantry crane is tailored to various lifting and material handling requirements, providing both efficiency and safety in operations.

List Product features of “3 ton gantry crane”

Sure! Here are the key features of a 3-ton gantry crane:

1. Load Capacity: Capable of lifting and moving loads up to 3 tons (6000 lbs).

2. Adjustable Height: Often features adjustable height settings to accommodate different lifting needs and workspace constraints.

3. Span Width: Varies in width to suit specific applications and spaces, ensuring versatility in different operational environments.

4. Material: Constructed from robust, high-quality materials like steel or aluminum for durability and long-term use.

5. Mobility: May include casters or wheels for easy repositioning and transport within a workspace; some models offer locking mechanisms for stability.

6. Hoist Compatibility: Designed to work with various types of hoists, including manual, electric, or pneumatic, for diverse lifting applications.

7. Ease of Assembly: Generally easy to assemble and disassemble, facilitating maintenance and relocation.

8. Safety Features: Equipped with safety latches, overload protection, and secure fastening options to ensure safe operation.

9. Paint and Finish: Often coated with a protective finish to resist corrosion, wear, and environmental factors.

10. Applications: Suitable for various industries including manufacturing, construction, automotive repair, and warehouses, providing a versatile lifting solution.

11. Compliance: Meets industry standards and regulations to ensure reliable and safe operation.

12. Customizable Options: Some models offer customization for specific requirements such as different heights, spans, and additional safety features.

These features make the 3-ton gantry crane a versatile and reliable tool for lifting heavy loads across a range of professional settings.

List Application of “3 ton gantry crane”

A 3-ton gantry crane is a versatile piece of lifting equipment designed for handling medium-weight loads. Here are notable applications:

1. Warehousing and Logistics: Ideal for lifting and moving heavy pallets, machinery, and other cargo within warehouses. Its mobility and lifting capacity streamline the handling of goods, reducing manual labor and increasing efficiency.

2. Manufacturing Plants: Used to transport parts, components, and finished products between different sections of a manufacturing facility. It assists in assembly lines, handling metal sheets, automotive parts, and other materials.

3. Construction Sites: Utilized for lifting and positioning construction materials such as steel beams, timber, and prefabricated elements. The crane aids in building structures, ensuring materials are safely and accurately placed.

4. Workshops and Fabrication Shops: Assists in the handling of heavy tools, dies, and machined parts, enhancing productivity in metal fabrication, carpentry, and other trades that deal with substantial items.

5. Maintenance and Repair Facilities: Essential in maintenance bays for lifting engines, gearboxes, and other heavy equipment. It supports automotive repair shops, aircraft maintenance hangars, and similar environments.

6. Dockyards and Marinas: Facilitates the movement of boats, ship parts, and marine equipment. Its utility in lifting heavy loads makes it indispensable for repairs and assembly in maritime settings.

7. Utilities and Municipal Services: Employed by utility companies for handling transformers, utility poles, and other heavy infrastructure components. Municipal services use it in maintenance yards for various public works projects.

Compact yet powerful, the 3-ton gantry crane’s ease of assembly and disassembly allows for excellent mobility, making it suitable for both indoor and outdoor use across various industries.

List Various Types of “3 ton gantry crane”

Sure! A 3-ton gantry crane is a versatile lifting device commonly used in industries like construction, manufacturing, and logistics. Here are various types of 3-ton gantry cranes:

1. Adjustable Height Gantry Crane:

– Feature: Adjustable vertical positioning.

– Benefit: Versatility for different lifting heights.

2. Fixed Height Gantry Crane:

– Feature: Fixed vertical positioning.

– Benefit: Stability and less setup time.

3. Portable Gantry Crane:

– Feature: Mobility with wheels/casters.

– Benefit: Easy to move around a workspace.

4. Track-Mounted Gantry Crane:

– Feature: Operates on a fixed rail system.

– Benefit: Precision in linear lifting and moving tasks.

5. Overhead (Ceiling-Mounted) Gantry Crane:

– Feature: Mounted on ceiling tracks.

– Benefit: Maximizes floor space for other operations.

6. Heavy Duty Gantry Crane:

– Feature: Robust design for rigorous applications.

– Benefit: Enhanced durability and lifting capacity.

7. Adjustable Span Gantry Crane:

– Feature: Adjustable horizontal beam length.

– Benefit: Adaptability to various workspace widths.

8. Aluminum Gantry Crane:

– Feature: Constructed from lightweight aluminum.

– Benefit: Easier to move and set up.

9. A-Frame Gantry Crane:

– Feature: A-frame design for stability.

– Benefit: Reliable for straightforward lifting tasks.

10. Steel Gantry Crane:

– Feature: Made of high-strength steel.

– Benefit: High load capacity and durability.

11. Electric Gantry Crane:

– Feature: Powered operation.

– Benefit: Efficient and less manual effort required.

12. Manual Gantry Crane:

– Feature: Hand-operated mechanisms.

– Benefit: Cost-effective for smaller operations.

These cranes are selected based on specific needs like mobility, height, span, material, and whether power or manual operation is preferred.

3 ton gantry crane Accessories Upgrades and Custom Manufacturing Options

Enhancing a 3-ton gantry crane with the right accessories and custom manufacturing options can significantly improve productivity, safety, and functionality. Here are several upgrades and customization options to consider:

Accessories:

1. Electric Hoists: Enhance lifting speed and ease of operation with electric hoists that offer precise control and greater efficiency.

2. Remote Controls: Implement wireless remote control systems for improved operator safety and flexibility, allowing crane operation from a distance.

3. Safety Lights and Alarms: Install LED warning lights and audible alarms to alert surrounding personnel of crane movement, enhancing workplace safety.

4. Load Weighing Systems: Integrate load cells or scales to constantly monitor load weights, preventing overload and ensuring compliance with safety regulations.

5. Adjustable Height Kits: Provide flexibility in lifting operations, accommodating various heights and spatial constraints.

6. C-Tracks and Festoon Systems: Facilitate organized cable management, preventing tangling and wear, and ensuring a cleaner workspace.

Upgrades:

1. VFD (Variable Frequency Drive): Enhance motor control for smooth acceleration and deceleration, reducing mechanical stress and improving performance.

2. Anti-Sway Control: Advanced control systems minimize load sway, increasing precision in load placement and operational safety.

3. Weatherproofing: For outdoor installations, apply weatherproof coatings, and use corrosion-resistant materials to extend the crane’s lifespan.

4. Automated Systems: Incorporate automation for repetitive tasks, reducing manual intervention and boosting efficiency.

5. Enhanced Mobility Options: Upgrade to motorized wheels for easy relocation and optimal flexibility, especially in large or multi-purpose workspaces.

Custom Manufacturing Options:

1. Custom Span and Height: Tailor the crane’s dimensions to meet specific workspace requirements.

2. Specialty Load Attachments: Design custom end effectors or gripping devices to handle unique load types and shapes.

3. Track and Rail Systems: Develop bespoke track systems for optimal crane maneuverability within your facility.

4. Custom Paint and Finishes: Apply specific coatings and colors for added protection and to meet corporate or safety standards.

Incorporate these accessories and upgrades to transform a standard 3-ton gantry crane into a versatile, efficient, and safer lifting solution tailored to your specific operational needs.

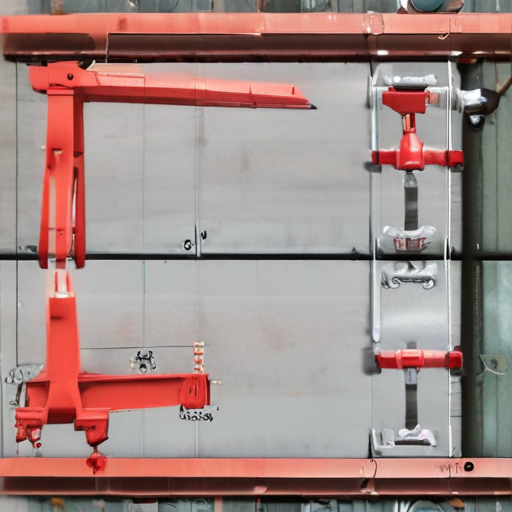

List Quality Control and The Manufacturing Process of “3 ton gantry crane”

Quality Control and Manufacturing Process of a 3-Ton Gantry Crane

Quality Control:

1. Material Inspection: Raw materials like steel undergo rigorous checks for specifications, integrity, and compliance with industry standards.

2. Component Testing: Critical components such as hoists, trolleys, and beams are tested for mechanical strength and durability.

3. Welding Inspection: Weld joints are examined using non-destructive testing (NDT) methods like ultrasonic or radiographic inspection to ensure structural integrity.

4. Load Testing: The assembled crane is subjected to load tests to verify its capability to handle its rated capacity without any failure.

5. Dimensional Accuracy: Parts and assembled cranes are checked to ensure they meet precise dimensional requirements.

6. Safety Checks: Functional tests for brakes, limit switches, and emergency stop mechanisms are performed.

7. Final Inspection: A comprehensive final inspection ensures that the crane meets all operational, safety, and compliance standards.

Manufacturing Process:

1. Design and Engineering:

– Begins with design drawings and structural analysis to meet specific requirements.

– Computer-Aided Design (CAD) used for precise specifications and simulation.

2. Material Preparation:

– Steel plates and profiles are cut to required sizes using CNC machines, laser cutters, or plasma cutters.

3. Assembly:

– Main parts such as the bridge beam, legs, and end trucks are assembled.

– Bolt and weld sub-assemblies for strength and stability.

4. Welding:

– Welders join parts using techniques like MIG or TIG welding.

– Quality of welds is continually monitored and inspected.

5. Machining and Finishing:

– Machining of critical parts to ensure accuracy.

– Surfaces are sandblasted and coated with anti-corrosive paint.

6. Component Integration:

– Hoist, trolley, wheels, and control systems are installed.

– Electrical wiring and control systems integration.

7. Testing:

– Load and operational tests performed to verify functionality and safety.

– Adjustments and fine-tuning as necessary.

8. Packaging and Delivery:

– Crane disassembled if required and packed for shipping.

– Detailed instructions provided for reassembly and installation.

This structured approach ensures that the 3-ton gantry crane is reliable, safe, and performs as expected in demanding industrial environments.

How to use “3 ton gantry crane”

A 3-ton gantry crane is a versatile piece of equipment used for lifting and moving heavy loads. Here’s a concise guide on how to use it safely and efficiently:

Step-by-Step Instructions:

1. Preparation

– Inspection: Check the crane for any signs of damage or wear. Ensure that the hoist, trolley, and rigging equipment are in good condition.

– Area Check: Make sure the work area is free of obstructions and that the ground is level and stable.

2. Setup

– Positioning: Place the gantry crane over the load. Make sure the crane legs are locked and stable.

– Adjust Height: If your crane is adjustable, set the height according to the load’s dimensions.

3. Rigging the Load

– Sling Placement: Attach slings or lifting straps securely to the load. Ensure the weight is evenly distributed.

– Hook Attachment: Attach the lifting hook to the sling or load. Double-check the attachment to ensure it’s secure.

4. Lifting the Load

– Hoist Operation: Using the control pendant or remote, slowly lift the load. Keep an eye on the load to ensure it remains stable.

– Clearance: Lift the load high enough to clear any obstacles but keep it as low as possible for safety.

5. Moving the Load

– Travel Path: Plan and clear the path before moving the load.

– Trolley Operation: Move the load horizontally by operating the trolley. Ensure smooth and controlled movements.

6. Lowering the Load

– Positioning: Move the load to its destination, ensuring it’s stable and won’t tip over.

– Lowering: Gently lower the load using the hoist controls. Guide the load to ensure it lands safely and in the correct position.

7. Post-Operation

– Inspection: Once done, inspect the crane and rigging equipment for any signs of wear or damage.

– Storage: Store the crane properly if it’s not in use, ensuring it’s secured and won’t pose a hazard.

Safety Tips:

– Always follow the manufacturer’s guidelines.

– Do not exceed the 3-ton weight limit.

– Wear appropriate PPE, such as gloves, safety shoes, and helmets.

– Ensure only trained personnel operate the crane.

“3 ton gantry crane” Comparative Analysis

Comparative Analysis of 3 Ton Gantry Cranes

#### Overview

A 3-ton gantry crane is a versatile lifting device commonly used in industries such as manufacturing, construction, and shipping. Key aspects to consider when comparing various 3-ton gantry cranes include design, material, cost, functionality, and mobility.

#### Types and Design

1. Fixed Gantry Cranes:

– Design: Stationary with a fixed height.

– Pros: Highly stable and reliable for repetitive tasks in a static location.

– Cons: Lack of flexibility; not suitable for varied-height operations.

2. Adjustable Gantry Cranes:

– Design: Adjustable height and span.

– Pros: Versatility to handle various applications and spaces.

– Cons: May require more setup time.

3. Portable Gantry Cranes:

– Design: Equipped with casters for mobility.

– Pros: Easily moved between locations, practical for temporary work sites.

– Cons: Generally less stable compared to fixed models.

#### Materials

– Steel Gantry Cranes:

– Pros: High strength, durable, suitable for heavy-duty tasks.

– Cons: Heavier, more difficult to transport.

– Aluminum Gantry Cranes:

– Pros: Lightweight, more portable, corrosion-resistant.

– Cons: Lesser load stability compared to steel.

#### Cost Analysis

– Steel Cranes: Generally more expensive due to material costs but offer longevity and robustness.

– Aluminum Cranes: Cost-effective for applications requiring frequent mobility.

#### Functionality

– Manual vs. Electric:

– Manual Cranes: Lower cost, simpler maintenance but require more physical effort.

– Electric Cranes: Higher initial cost, efficient for frequent lifting, require power source.

#### Mobility

– Fixed and Adjustable Gantry Cranes: Suitable for permanent or semi-permanent setups.

– Portable Gantry Cranes: Ideal for dynamic work environments, easier relocation.

Conclusion

Selecting the right 3-ton gantry crane depends on specific operational needs. For static, heavy-duty tasks, a fixed steel gantry crane is optimal. For flexibility and mobility, an adjustable or portable aluminum crane is preferable. Balancing material, cost, functionality, and mobility ensures the most efficient solution for lifting needs.

“3 ton gantry crane” Warranty and Support

When purchasing a 3-ton gantry crane, it’s crucial to consider the warranty and support offered by the manufacturer to ensure reliability and ease of maintenance. Typically, manufacturers provide a robust warranty that spans one to three years, covering defects in materials and workmanship. Some premium brands might offer extended warranties, often available for an additional cost, which provide further peace of mind.

The warranty generally covers key components such as the hoist, trolley, and gantry structure. However, it’s important to thoroughly read the warranty terms, as exclusions commonly apply to parts subject to regular wear and tear, such as cables and brakes. Additionally, improper use or unauthorized modifications can void the warranty.

Support is another vital aspect. Reputable manufacturers offer comprehensive customer support, including 24/7 technical assistance via phone, email, or chat. Many also provide detailed user manuals and online resources, such as troubleshooting guides and instructional videos, to assist with common issues.

Maintenance services, either on-site or at designated service centers, ensure that your crane remains in optimal condition. Some manufacturers offer periodic maintenance contracts, which include regular inspections, adjustments, and part replacements as needed.

In case of a malfunction, swift response times for repairs minimize downtime, which is critical in high-paced industrial environments. Advanced diagnostic tools and remote support capabilities can expedite troubleshooting and repairs.

Lastly, consider the availability of spare parts. Manufacturers with a global distribution network can provide quick delivery of parts, ensuring minimal disruption to your operations.

In summary, a strong warranty and robust support network are paramount when investing in a 3-ton gantry crane. Ensure you understand the terms and availabilities to maximize the longevity and efficiency of your equipment.

List “3 ton gantry crane” FAQ

1. What is a 3 ton gantry crane?

A 3 ton gantry crane is a type of equipment used for lifting and transporting heavy loads up to 3 tons. It typically consists of a horizontal beam (girder) supported by two A-frame legs, with wheels for mobility.

2. What are the applications of a 3 ton gantry crane?

It is used in various industries, including manufacturing, shipping, construction, and warehouses for tasks such as loading and unloading materials, assembly, and maintenance.

3. What types of 3 ton gantry cranes are available?

There are fixed-height, adjustable-height, portable, and motorized gantry cranes. The choice depends on the specific needs, like height adjustment and mobility requirements.

4. What are the benefits of using a gantry crane?

Advantages include flexibility in lifting operations, ease of installation, reduced need for permanent infrastructure, and the ability to handle a wide range of lifting tasks efficiently.

5. What factors should be considered when selecting a 3 ton gantry crane?

Key factors include load capacity, height, span length, indoor or outdoor use, portability, and any specific industry standards or regulatory requirements.

6. How is a 3 ton gantry crane powered?

It can be manually operated or powered by electric motors for hoisting and trolley movement, depending on the specific model and user requirements.

7. What safety precautions are necessary when operating a 3 ton gantry crane?

Operators should undergo proper training, conduct regular inspections, follow weight limits, use appropriate personal protective equipment (PPE), and ensure the crane is used on level surfaces.

8. How do you maintain a 3 ton gantry crane?

Regular maintenance includes inspecting for wear and tear, lubricating moving parts, checking for structural integrity, and timely repairs to prevent accidents and extend the crane’s lifespan.

9. What is the usual lifespan of a 3 ton gantry crane?

With proper maintenance, a gantry crane can last between 10-20 years, depending on usage frequency and operating conditions.

10. Can a 3 ton gantry crane be customized?

Yes, they can be customized to meet specific operational needs regarding height, span, power options, and additional features like motorization or wireless controls.

Through these frequently asked questions, you can better understand the functionalities, applications, and maintenance of a 3 ton gantry crane, ensuring effective and safe usage.

Top 10 FAQ with answer about 3 ton gantry crane for Buyer Sourcing from China

1. What is a 3-ton gantry crane?

A 3-ton gantry crane is a lifting device with a maximum lifting capacity of 3 tons, used for various industrial applications like loading, unloading, and moving heavy materials.

2. What types of 3-ton gantry cranes are available?

Common types include single girder, double girder, and adjustable height gantry cranes. Each type is suitable for different operational needs and environments.

3. What materials are used in construction?

High-quality steel is typically used for the structural components, ensuring durability and strength. Some parts may also incorporate aluminum for reduced weight.

4. Can I customize the 3-ton gantry crane according to my needs?

Yes, most manufacturers offer customization options, such as different span lengths, heights, and additional features like motorized travel or hoisting.

5. What is the lead time for manufacturing and delivery?

Generally, the lead time ranges from 4 to 8 weeks for manufacturing. Shipping time depends on the destination, but it usually takes an additional 2 to 4 weeks.

6. What safety features are included?

Common safety features include overload protection, emergency stop buttons, limit switches, and anti-collision devices.

7. Is installation and maintenance support available?

Many Chinese suppliers offer installation guidelines, manuals, and even on-site support. Additionally, they provide maintenance services and spare parts.

8. How do I ensure the quality and reliability of the crane?

Purchase from a reputable manufacturer. Look for certifications like ISO, CE, and others. Reading customer reviews and asking for a product test report also helps.

9. What are the payment terms?

Payment terms vary, but common options include T/T (Telegraphic Transfer), L/C (Letter of Credit), and partial payments (30% advance, 70% before shipping).

10. How do I handle customs and import duties?

Consult with a freight forwarder for a smooth import process. They can help with customs clearance, paperwork, and duty calculations, ensuring compliance with your country’s regulations.