30 ton crane Safety Certifications

Ensuring the safe operation of a 30-ton crane involves several key safety certifications. These certifications help to verify that the crane meets established safety standards and that operators are adequately trained.

1. OSHA Compliance (Occupational Safety and Health Administration):

– Adhering to OSHA standards (e.g., 29 CFR 1926 for construction cranes) is mandatory in the U.S. This ensures safe design, operation, and maintenance practices.

2. ASME B30.5:

– The American Society of Mechanical Engineers standard for mobile and locomotive cranes outlines safety practices for construction, inspection, testing, maintenance, and operation.

3. NCCCO Certification (National Commission for the Certification of Crane Operators):

– Crane operators must be certified by NCCCO or another accredited body, ensuring they are competent to manage crane operations safely.

4. ANSI Standards (American National Standards Institute):

– ANSI B30.5 correlates with ASME standards and provides additional guidelines on crane safety and operation.

5. API Standards (American Petroleum Institute):

– For cranes used in the oil and gas industry, compliance with API standards such as API RP 2D is necessary for offshore crane operations.

6. LOLER (Lifting Operations and Lifting Equipment Regulations):

– In the UK, LOLER requires thorough examinations of lifting equipment by a competent person to ensure safety and compliance.

7. Periodic Inspections:

– Regular inspections and maintenance reports are crucial to ensure that the crane remains in safe operating condition. This includes daily checks and annual comprehensive inspections often mandated by safety authorities.

8. Load Testing:

– Certification that the crane has undergone load testing as per manufacturer guidelines and industry regulations is important. This includes ensuring it can handle loads up to its rated capacity without malfunction.

9. ISO 9927:

– Adherence to international standards like ISO 9927 ensures consistent safety protocols across various regions and industries.

These certifications and adherence to safety standards are crucial in mitigating risks, protecting workers, and ensuring the safe operation of 30-ton cranes.

List Reference Technical Parameters of “30 ton crane”

A “30 ton crane” refers to a crane capable of lifting loads up to 30 tons. Here are some typical technical parameters to consider:

1. Lifting Capacity: 30 tons (27,215 kg).

2. Boom Length: Varies by model but generally ranges from 30 to 60 meters.

3. Jib Length: Additional jib extensions can range from 8 to 20 meters.

4. Max Lifting Height: Up to 70 meters with combined boom and jib.

5. Outreach: Can range from 20 to 40 meters depending on boom and jib configuration.

6. Swing Speed: Typically around 2-3 rpm.

7. Lifting Speed: Variable depending on load, ranging from 1 to 15 meters per minute.

8. Travel Speed: Maximum travel speed can be around 5 to 10 km/h for mobile cranes.

9. Type: Mobile, tower, overhead, or crawler cranes.

10. Power Source: Diesel engines for mobile cranes, electric motors for overhead and tower cranes.

11. Control System: Modern cranes use computerized control systems for precision operations; may include remote control for additional safety.

12. Stability Features: Outriggers, counterweights, and stabilizing systems to prevent tipping.

13. Safety Devices: Load moment indicators, anti-two blocking systems, and emergency stop functions.

14. Operating Temperature Range: Typically designed to operate between -20°C to 40°C.

15. Tire Specifications: For mobile cranes, size and type vary based on terrain capabilities.

16. Dimensions: Overall dimensions (length, width, height) depend on crane type and model.

Always consult the specific manufacturer’s data sheet for precise technical parameters.

List Product features of “30 ton crane”

Certainly! Here are the product features of a “30 ton crane”:

1. Load Capacity: Designed to lift and handle loads up to 30 tons, making it suitable for heavy-duty applications across various industries.

2. Boom Length: Equipped with an extendable boom that can vary in length, typically ranging from 30 to 50 meters, to reach significant heights and distances.

3. Mobility: Often available in mobile versions, such as truck-mounted or all-terrain cranes, ensuring flexible and convenient transport to different job sites.

4. Operational Flexibility: Some models offer telescopic or lattice booms and can be customized with jib extensions for additional reach and versatility.

5. Control Systems: Advanced models feature computerized control systems for precise load handling, which include load moment indicators, anti-sway technology, and automatic leveling.

6. Safety Features: Comes with numerous safety mechanisms such as overload protection, emergency shut-off systems, and stabilizer systems to ensure safe operations.

7. Power Options: Typically powered by diesel engines, but electric or hybrid models are also available to suit various environmental conditions and regulatory requirements.

8. Durability: Made from high-strength steel and other robust materials to withstand harsh conditions and prolonged usage.

9. Ease of Assembly: Designed for quick setup and teardown, often featuring modular components and hydraulic systems to expedite the process.

10. Ergonomics: Features comfortable operator cabins with climate control, ergonomic seating, and clear visibility to enhance operator comfort and efficiency.

11. Maintenance Features: Includes accessible service points and diagnostic systems to simplify routine maintenance and repairs.

12. Versatility: Suitable for various applications including construction, shipping, manufacturing, and heavy lifting tasks.

13. Compliance: Conforms to industry standards and safety regulations to ensure operational reliability and adherence to legal requirements.

This 30-ton crane is engineered to deliver powerful lifting capabilities, operational versatility, and safety, making it a vital asset for heavy-duty lifting tasks.

List Various Types of “30 ton crane”

Certainly! Below are various types of “30 ton cranes,” each suited for specific applications and environments:

1. Mobile Crane:

– Truck-mounted Crane: Features a crane cabin mounted on a truck, ideal for road travel and site-to-site transfers.

– All-Terrain Crane: Combines roadworthiness with off-road capabilities, suitable for diverse terrains and applications.

2. Crawler Crane:

– Equipped with tracks instead of wheels, providing stability on rough surfaces and enabling easy transport across various terrains. It’s ideal for heavy lifting and long-term projects.

3. Tower Crane:

– Used mainly in construction for high-rise buildings. It features a fixed base and a tall, lattice mast, offering height and lifting capacity.

4. Rough Terrain Crane:

– Built for off-road operations, it features four large, rubber-tire wheels and can handle uneven surfaces with ease.

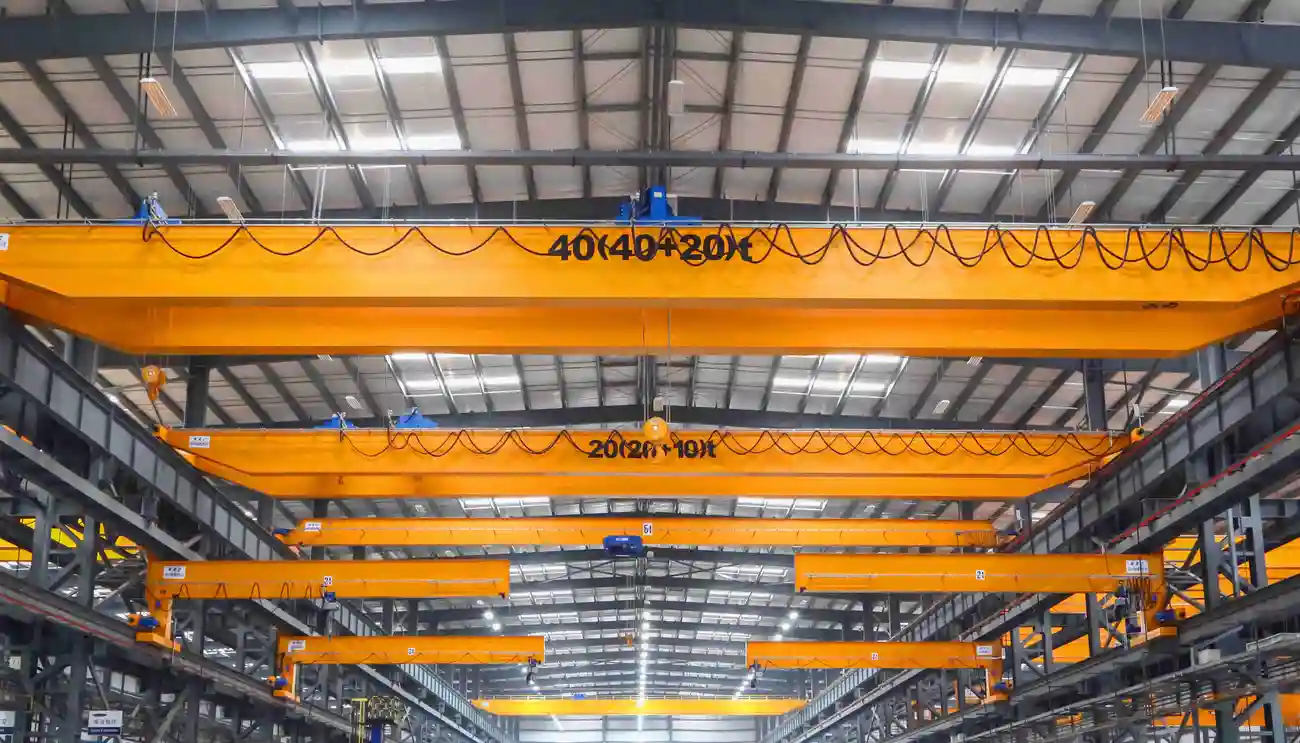

5. Overhead Crane:

– Also known as a bridge crane, this type runs on elevated tracks called runways, typically found in industrial environments like factories and warehouses.

6. Gantry Crane:

– Similar to an overhead crane but with wheels, allowing it to move directly on the ground. It’s often used in shipyards and large outdoor worksites.

7. Hydraulic Crane:

– Utilizes hydraulic systems for lifting, offering precision and ease of control. These are versatile and can be either truck-mounted or part of other crane systems.

Each type of 30 ton crane provides unique advantages depending on the operational requirements, site conditions, and lifting needs. Selecting the appropriate crane type is crucial for optimizing efficiency, safety, and cost-effectiveness for specific projects.

List Application of “30 ton crane”

A 30-ton crane is a versatile piece of heavy machinery capable of lifting substantial loads, commonly utilized across various industries. Here are some of its primary applications:

1. Construction: Frequently employed for hoisting steel beams, concrete panels, and other heavy construction materials to considerable heights. An essential tool in the assembly of high-rise buildings, bridges, and large infrastructure projects.

2. Manufacturing: Used to move heavy machinery, equipment, and large components within factory settings. Facilitates the assembly and maintenance of large-scale manufacturing operations.

3. Shipping and Logistics: Dockyards and ports utilize 30-ton cranes to load and unload shipping containers and large cargo from ships, aiding in the efficient transfer of goods.

4. Mining: Critical for lifting heavy mining equipment, extracting ores, and transporting large rock and soil samples. Enhances operational efficiency in open-pit and underground mining operations.

5. Oil and Gas: Essential on offshore platforms and refineries for lifting heavy pipes, equipment, and components. Assists in the construction and maintenance of oil rigs and related infrastructure.

6. Power Generation: Used in power plants for the installation and maintenance of heavy turbines, generators, and other critical infrastructure. Supports both conventional and renewable energy projects.

7. Railways: Facilitates the repair and installation of railway tracks, and assists in the maintenance and placement of railway cars and engines.

8. Demolition: Employed to lift heavy debris and dismantle large structures safely and efficiently, aiding in site clearance.

9. Event Management: Utilized for setting up large stages, arenas, and other heavy structures for entertainment and sporting events.

In summary, a 30-ton crane’s ability to lift and maneuver heavy loads makes it indispensable across various sectors, enhancing efficiency and productivity in complex operations.

List Buyer Types of “30 ton crane”

The buyer types for a 30-ton crane encompass a range of industries and organizations. Here are the key buyer categories:

1. Construction Companies: These firms need 30-ton cranes for lifting heavy materials, steel beams, and other construction elements. The crane’s capabilities help them complete large-scale projects efficiently.

2. Manufacturing Plants: Factories with significant in-house heavy equipment or those involved in the production of large machinery components often purchase 30-ton cranes for material handling and assembly line tasks.

3. Logistics and Warehousing Firms: Companies offering logistics solutions may require such cranes for loading and unloading heavy freight, optimizing storage, and transferring large containers.

4. Transport and Shipping Companies: Ports and shipping companies use 30-ton cranes for efficiently moving goods from freight ships to dockside storage or transport vehicles.

5. Utility Services: Utility providers, including those in power generation, water services, and telecommunications, use cranes for installation and maintenance of heavy infrastructure such as transformers, pipes, and communication towers.

6. Mining Operations: Mining companies utilize 30-ton cranes to handle large mining equipment, relocate materials, and maintain operational efficiency in harsh environments.

7. Aerospace Industry: Aerospace companies need robust lifting solutions for assembling aircraft and handling spacecraft components, making a 30-ton crane crucial for their operations.

8. Oil and Gas Sector: Cranes are essential for moving heavy drilling equipment, pipelines, and other infrastructure critical to oil and gas extraction and refining processes.

9. Rental Companies: Firms specializing in leasing equipment acquire 30-ton cranes to rent them out to various industries needing temporary heavy-lifting solutions.

10. Municipalities and Government Agencies: These entities often require cranes for public infrastructure projects such as bridge construction, roadwork, and emergency response situations.

11. Agricultural Operations: Large-scale farming enterprises might use cranes to move heavy agricultural machinery or materials, enhancing productivity in agribusiness.

Each of these buyer types values the 30-ton crane for its blend of lifting power, versatility, and efficiency in handling heavy-duty tasks across various settings.

List “30 ton crane” Project Types for Different Industries

Sure, here are some common project types that might utilize a 30-ton crane across different industries:

1. Construction:

– High-rise Building Erection: Lifting steel beams and prefabricated sections.

– Bridge Construction: Moving large structural components.

– Residential Building: Handling modular housing units.

– Infrastructure Projects: Roadway and tunnel support.

2. Manufacturing:

– Heavy Equipment Assembly: Assembling machinery components.

– Machinery Relocation: Moving heavy manufacturing equipment within or between facilities.

– Material Storage: Organizing large stacks of raw materials.

3. Energy:

– Wind Farm Installation: Erecting wind turbines.

– Oil and Gas: Positioning large pipes and equipment.

– Solar Farms: Installing large solar panels or components.

4. Shipping and Logistics:

– Port Operations: Loading and unloading shipping containers.

– Railway Maintenance: Setting large tracks or equipment.

5. Maintenance and Repair:

– Industrial Maintenance: Replacing or installing large industrial machinery.

– Utility Maintenance: Repairing or setting large utility poles and transformers.

6. Mining:

– Equipment Handling: Moving large mining equipment.

– Facility Construction: Handling structural elements for new facilities.

7. Aerospace:

– Aircraft Assembly: Lifting large components during the assembly process.

– Facilities Maintenance: Handling heavy maintenance tasks at aerospace manufacturing plants.

8. Entertainment:

– Stage and Set Construction: Lifting heavy set pieces for concerts or theatrical productions.

– Event Setup: Installing large temporary structures for festivals or sporting events.

Each industry has specific needs and requirements, but the versatility of a 30-ton crane allows it to perform a wide range of lifting and handling tasks efficiently.

30 ton crane Accessories Upgrades and Custom Manufacturing Options

When upgrading a 30-ton crane, several accessories and custom manufacturing options are available to enhance its performance, safety, and functionality.

Accessories:

1. Wireless Remote Control: Offers better maneuverability and safety by allowing operators to control the crane from a distance.

2. Anti-Collision Systems: Infrared or laser-based systems to prevent crane collisions in busy sites.

3. Load Moment Indicators (LMIs): Enhance safety by monitoring and displaying the load weight and operational status.

4. Camera Systems: High-definition cameras provide better visibility, especially in hard-to-see areas.

5. Weatherproof Covers: Protect the crane’s mechanical and electrical components from harsh weather conditions.

6. LED Lighting Kits: Improve visibility during night operations or in poorly lit environments.

7. Rigging Accessories: Shackles, slings, and spreader bars for versatile lifting operations.

Custom Manufacturing Options:

1. Boom Customization: Enhance reach and flexibility with custom-length booms or jib extensions.

2. Operator Cab Modifications: Ergonomic upgrades, climate control, and improved visibility for better operator comfort and efficiency.

3. Hoist Upgrades: Increase lifting speed and precision by installing more advanced hoisting mechanisms.

4. Track or Wheel Modifications: Adapt the crane for specific terrains with track modifications or specialized wheels.

5. Power Source Options: Custom-engineered solutions for hybrid or electric power systems to reduce emissions and improve energy efficiency.

6. Enhanced Safety Features: Custom safety interlocks, emergency stop systems, and overload protection.

7. Material Upgrades: Use of high-strength, lightweight materials to improve the crane’s load capacity and longevity.

By selecting the appropriate accessories and custom manufacturing options, a 30-ton crane can be effectively tailored to meet specific operational needs, improve safety, and enhance overall productivity.

List Quality Control and The Manufacturing Process of “30 ton crane”

Quality Control and Manufacturing Process of a 30-Ton Crane

Manufacturing Process:

1. Design and Engineering:

– Needs Analysis: Determine customer requirements and project specifications.

– CAD Modeling: Develop detailed 3D models and blueprints.

2. Material Procurement:

– Material Selection: Choose high-strength steel and other necessary materials.

– Supplier Assessment: Evaluate and verify material suppliers for quality.

3. Fabrication:

– Cutting: Laser or plasma cutting of steel plates and beams.

– Welding: Assemble components using certified welders.

– Machining: Precision machining of components such as gears and bearings.

4. Assembly:

– Pre-Assembly Checks: Inspect components for defects and compliance.

– Sub-Assembly: Assemble smaller modules like the hoist and trolley.

– Main Assembly: Integrate sub-assemblies into the main framework.

5. Testing and Calibration:

– Load Testing: Verify lifting capacity and structural integrity.

– Electrical Testing: Ensure proper functioning of control systems.

6. Finishing:

– Painting: Apply corrosion-resistant and wear-resistant coatings.

– Final Inspection: Comprehensive review before packaging.

Quality Control:

1. Incoming Inspection:

– Material Verification: Confirm materials meet required specifications.

– Document Review: Validate supplier certifications and test reports.

2. In-Process Inspection:

– Welding Checks: Non-destructive testing (NDT) like ultrasonic or radiographic tests.

– Dimensional Accuracy: Use precision tools to ensure components meet design tolerances.

3. Final Inspection:

– Functional Testing: Check operational functionality including load and stress tests.

– Safety Checks: Verify compliance with industry safety standards.

4. Documentation and Traceability:

– Records: Maintain quality control records for traceability.

– Compliance: Ensure adherence to ISO and other relevant standards.

5. Continuous Improvement:

– Feedback Loop: Collect data from end-users for quality enhancements.

– Review Meetings: Periodic quality assessment meetings for continuous improvement.

By integrating stringent quality control measures throughout the manufacturing process, the 30-ton crane ensures reliability, safety, and performance consistency.

How to use “30 ton crane”

Using a 30-ton crane involves several key steps for safe and efficient operation. Here’s a concise guide:

1. Pre-Operation Checks:

– Inspect the crane: Check for any visible damage or defects.

– Verify load capacity: Ensure the 30-ton limit isn’t exceeded.

– Safety gear: Equip necessary safety gear like helmets, gloves, and steel-toe boots.

2. Setting Up:

– Stabilize the crane: Extend outriggers fully and use cribbing for stable ground contact.

– Level the crane: Use onboard leveling tools to ensure the crane is horizontal.

3. Planning the Lift:

– Load weight: Confirm the weight of the load. It must be within the crane’s capacity.

– Lift path: Identify a clear and safe path for the load, avoiding obstacles.

– Communication: Establish hand signals or radio communication with the ground crew.

4. Lift Execution:

– Hook up the load: Securely attach slings or lifting devices to the load.

– Tension the lines: Slowly lift until lines are taut and check for balance.

– Slow lift: Gradually lift the load, monitoring stability and surroundings.

– Rotate and move: Use crane controls to maneuver the load to the desired location.

– Lower the load: Slowly lower the load into position, ensuring it remains stable.

5. Post-Operation:

– Secure the crane: Retract the boom, stow the hook, and retract outriggers.

– Inspect again: Check the crane and tackle for any damage post-operation.

– Documentation: Log the lift details and any issues encountered for records.

Safety is paramount. Ensure all operators are trained and certified, and always follow the manufacturer’s guidelines.

“30 ton crane” Comparative Analysis

A 30-ton crane is a versatile piece of heavy machinery commonly utilized in construction, manufacturing, and transport sectors for lifting and moving substantial loads. This comparative analysis will consider various types of 30-ton cranes, mainly mobile, overhead, and tower cranes.

Mobile Cranes: These cranes are mounted on wheels or tracks, offering exceptional mobility and versatility. They can swiftly move to different locations within a job site. Mobile cranes can be further classified into truck-mounted cranes, rough-terrain cranes, and all-terrain cranes. Truck-mounted cranes are ideal for urban areas due to their road mobility, while rough-terrain and all-terrain cranes are better suited for off-road conditions. However, their stability can be a concern, and they often require outriggers.

Overhead Cranes: Also known as bridge cranes, these are fixed installations within manufacturing or warehouse environments. They consist of one or two beams to which the lifting mechanism is attached. Overhead cranes are incredibly efficient for indoor applications, providing precise load handling and maximizing workspace area. They are limited by their fixed position and cannot be used outside the predetermined path.

Tower Cranes: Primarily used in the construction of tall buildings, tower cranes offer impressive height and lifting capacity. They are fixed to the ground or attached to the sides of structures and can reach significant heights and distances. Although incredibly powerful, tower cranes are not mobile and involve more extended installation and dismantling times. They also require skilled operators and substantial planning.

In summary, the selection of a 30-ton crane depends on specific project requirements. Mobile cranes offer flexibility and mobility, overhead cranes excel in controlled environments with repetitive tasks, and tower cranes provide unmatched height and lifting capacity for tall construction projects. Each type has its advantages and limitations, making situational suitability a critical factor in decision-making.

“30 ton crane” Warranty and Support

Warranty and Support for 30-Ton Crane

#### Warranty Coverage:

Our 30-ton crane comes with a comprehensive warranty to ensure your investment is protected. The warranty covers the following:

1. Duration: Standard warranty period is 24 months from the date of delivery.

2. Parts and Labor: During the warranty period, any manufacturing defects in materials or workmanship will be repaired or replaced at no cost to the customer.

3. Structural Integrity: Coverage includes the crane’s structural components, including the boom, frame, and undercarriage.

4. Hydraulic and Electrical Systems: Any issues arising within the hydraulic and electrical systems due to factory defects will also be covered.

#### Exclusions:

The warranty does not cover:

– Normal wear and tear

– Damage due to misuse, overloading, or lack of proper maintenance

– Unauthorized modifications or use of non-genuine parts

#### Extended Warranty:

An extended warranty option is available for purchase, extending the coverage by an additional 12 or 24 months. This allows for continued support and peace of mind.

#### Support Services:

We offer robust support services to ensure your 30-ton crane remains in optimal condition:

1. 24/7 Customer Support: Our dedicated support team is available 24/7 to answer any questions and provide assistance.

2. On-Site Service: Trained technicians are available for on-site repairs and maintenance, ensuring minimal downtime.

3. Scheduled Maintenance: We offer scheduled maintenance plans to help keep your crane in top operating condition and extend its lifespan.

4. Training and Consultation: Initial operator training and ongoing consultation services are provided to ensure safe and efficient use of your equipment.

#### Spare Parts:

We maintain a comprehensive inventory of genuine spare parts, ensuring quick replacement and minimal downtime in case repairs are necessary.

#### Documentation:

All necessary documentation, including user manuals, maintenance schedules, and service logs, will be provided upon delivery to facilitate proper use and upkeep.

For further information or to request support, please contact our customer service department.

List “30 ton crane” FAQ

30 Ton Crane FAQ

1. What is a 30-ton crane?

A 30-ton crane is a lifting machine capable of lifting loads up to 30 tons (27,215 kilograms). It is commonly used in construction, industrial, and transportation sectors for lifting and moving heavy materials.

2. What types of 30-ton cranes are available?

There are various types, including mobile cranes, tower cranes, overhead cranes, and crawler cranes. The choice depends on the application and terrain.

3. What are the key specifications?

Key specifications include maximum lifting capacity (30 tons), maximum height (varies by model), boom length, and overall dimensions. Ensure the crane fits your project’s requirements.

4. How is a 30-ton crane powered?

It can be powered by diesel engines, electric motors, or hybrid systems, depending on the model and use case.

5. What safety features are included?

Common safety features include load moment indicators (LMI), anti-two block devices, overload protection, and stabilizers or outriggers for balance.

6. Do operators need certification?

Yes, operators usually need specific training and certification to safely and legally operate a 30-ton crane.

7. What are the common uses?

They are used for heavy lifting in construction sites, shipyards, manufacturing facilities, and for infrastructure projects like bridges and highways.

8. What factors influence crane rental costs?

Cost factors include duration of rental, crane type, location, mobilization/demobilization fees, and any additional equipment needed.

9. Can it operate on rough terrain?

Certain models, such as rough terrain and crawler cranes, are designed to operate on uneven and rugged surfaces.

10. What routine maintenance is required?

Routine checks include inspecting the hoist, hydraulic systems, boom, cables, and safety devices. Regular maintenance helps ensure safe and efficient operation.

11. How should it be transported?

Transport typically involves a flatbed truck for mobile cranes or dismantling larger cranes for transportation by multiple vehicles.

12. Where can I rent or buy a 30-ton crane?

They can be rented or purchased from specialized crane hire companies, heavy equipment dealers, or directly from manufacturers.

13. What are the advantages of using a 30-ton crane?

Efficiently lifts heavy loads, improves productivity, reduces manual labor, and enhances safety on the job site.

Top 10 FAQ with answer about 30 ton crane for Buyer Sourcing from China

Certainly! Here are the top 10 frequently asked questions (FAQ) for buyers sourcing a 30-ton crane from China:

1. What types of 30-ton cranes are available?

– In China, you can source various types such as overhead cranes, mobile cranes, truck-mounted cranes, and tower cranes, each catering to specific industrial needs.

2. What is the lead time for delivery?

– Typically, the lead time ranges from 4 to 12 weeks, depending on the crane model, customization requirements, and the manufacturing schedule.

3. What are the key specifications of a 30-ton crane?

– Key specifications include maximum lifting capacity (30 tons), lifting height, span, speed (lifting, trolley, and crane traveling), and power supply requirements.

4. Are Chinese-made cranes compliant with international standards?

– Yes, many Chinese manufacturers comply with international standards such as ISO, CE, and ANSI to ensure quality and safety. Verify certifications before purchase.

5. What after-sales services are provided?

– Standard after-sales services include installation support, operator training, maintenance, and a warranty period (typically 1-2 years). Ensure to discuss specific service agreements with the supplier.

6. Can the crane be customized to specific requirements?

– Yes, Chinese manufacturers often offer customization options to meet specific operational needs, such as specialized lifting attachments, control systems, and power sources.

7. How does shipping and logistics work?

– Cranes are generally shipped by sea due to their size. The manufacturer arranges shipping, but buyers may need to handle customs clearance and inland transportation.

8. What is the cost of a 30-ton crane?

– Prices vary based on the type and specifications but typically range from $50,000 to $150,000. Request detailed quotations from multiple suppliers for comparisons.

9. How reliable are Chinese crane manufacturers?

– There are numerous reputable manufacturers in China. Research the company’s reputation, client testimonials, and past project examples to ensure reliability.

10. What payment terms do Chinese manufacturers offer?

– Common payment terms include a 30% deposit with the balance paid before shipment. Letter of Credit (L/C) and other secure payment methods are also often accepted.

This concise overview addresses key concerns and provides a foundational understanding for buyers interested in sourcing a 30-ton crane from China.